How Friction Stir Welding Supports NASA’s First Crewed Artemis II Mission

How Friction Stir Welding Supports NASA’s First Crewed Artemis II Mission

For the Artemis II mission- the first crewed flight of NASA’s Space Launch System (SLS) and Orion spacecraft- every component must meet the highest standards for strength, reliability, and repeatability. This mission isn’t just about proving technology works, it’s about proving it works with humans onboard.

At the heart of this effort is friction stir welding (FSW)- a solid-state joining process that produces exceptionally strong, low-distortion welds with no added filler material. PAR Systems’ I-STIR friction stir welding technology continues to support the manufacturing of critical structural hardware for the SLS launch vehicle and the Orion spacecraft, building on the same proven processes used during Artemis I.

Above: NASA is working to land the first woman and first person of color on the Moon under Artemis. SLS is part of NASA’s backbone for deep space exploration, along with Orion and the Gateway in orbit around the Moon, and commercial human landing systems. SLS is the only rocket that can send Orion, astronauts, and supplies to the Moon in a single mission. (Source: NASA)

Where Friction Stir Welding Is Used on Artemis II Hardware

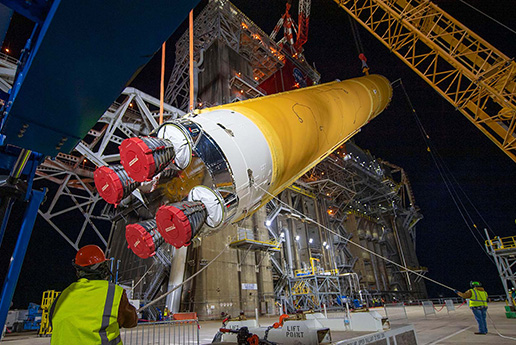

For Artemis II, friction stir welding plays a key role in the production of large, load-bearing structures that must withstand the extreme forces of launch and deep space flight. PAR’s FSW systems are used to join major components of the SLS rocket, including elements of the core stage fuel tanks, which store the liquid hydrogen and liquid oxygen required for liftoff.

These tanks are constructed from multiple subcomponents- such as barrels, domes, and rings- that must be precisely welded together to form a single, structurally sound assembly. In many cases, individual barrel and dome sections are first fabricated from welded panels before being joined into full tank structures. Friction stir welding enables these joints to be completed with exceptional strength and minimal distortion, even at the massive scale required for SLS.

PAR’s FSW technology also supports welding of stage adapter structures and structural elements of the Orion crew module, where consistent weld quality is essential for both performance and crew safety.

Image credits: NASA

Why It Matters for Artemis II

Unlike traditional fusion welding processes, friction stir welding joins materials without melting them, resulting in joints that are lighter, stronger, and more uniform. For human-rated spaceflight, these characteristics are critical.

Every pound saved in structural weight can be reallocated to payload, mission capability, or safety margin. At the same time, the integrity of welded joints must be beyond question- especially for components that experience cryogenic temperatures, vibration, and extreme mechanical loads.

“Going from an uncrewed test flight to a crewed mission raises the stakes,” says Jim Freeman, Chief Engineer for Friction Stir Welding at PAR Systems. “Our technology helps ensure the structures carrying astronauts are as strong and reliable as possible.”

From Proven Manufacturing to Human-Flight Readiness

Artemis II represents a transition point for the Artemis program- from validating systems in flight to demonstrating readiness for sustained human exploration. The friction stir welded structures supporting SLS and Orion reflect that progression: manufacturing processes that were proven during Artemis I are now being relied upon to support astronauts on a mission beyond low Earth orbit.

As NASA prepares to send four astronauts on a free-return trajectory around the Moon, PAR’s friction stir welding systems remain part of the manufacturing infrastructure that makes that journey possible- quietly enabling the strength, efficiency, and reliability required for human spaceflight.