Configurable, Robotic Fixtures

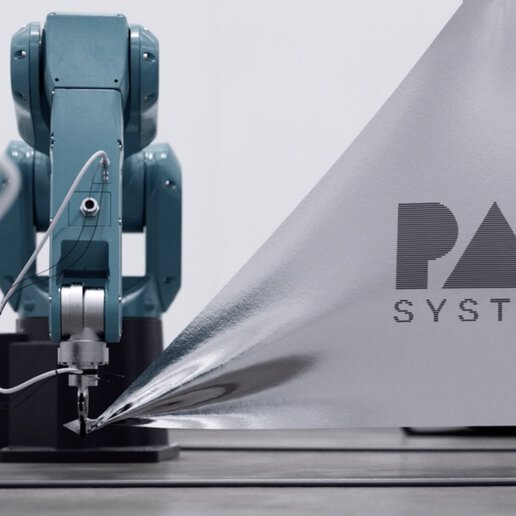

Using adaptive manufacturing strategies, PAR Systems designs and develops configurable robotic fixtures that result in impactful ROI and gains in manufacturing efficiency and productivity.

What PAR Configurable, Robotic Fixtures Offer to Manufacturers

PAR can design and develop configurable, robotic fixtures to address your full range of parts while ensuring the fixture is appropriate for your manufacturing process. Robotic fixtures are sometimes referred to as flexible fixtures because they are designed to be adjustable and adaptable to different tooling needs. However, the positioning and holding of parts remains rigid, so PAR uses the language of configurable and robotic to avoid confusion.

Configurable fixtures allow an entire family of parts to be managed with one fixture that remains within the machine footprint. They reduce or eliminate the need for dedicated tooling and the associated design, production, maintenance, storage, and handling costs.

Configurable, robotic fixture capabilities

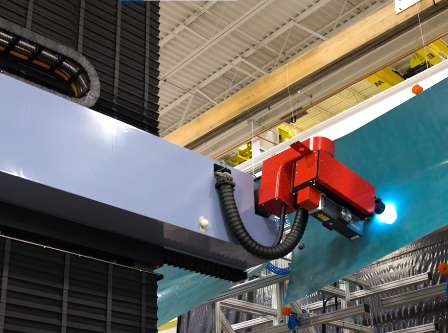

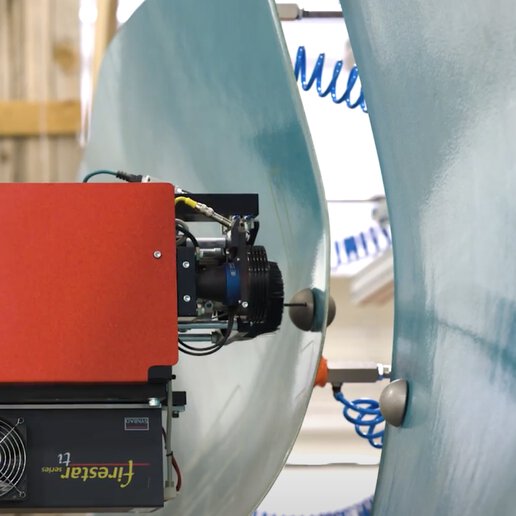

Robotic fixtures can be used for multiple manufacturing processes, eliminating dedicated tooling and making the following processes more flexible and efficient:

- Assembly

- Cutting & trimming

- Cleaning

- Inspection

- Drilling

- Additive materials

- Material removal

- Laser processing

Features of flexible manufacturing systems with configurable fixtures

Our configurable, robotic fixtures are an effective and cost-efficient solution that help manufacturers improve flexible and adaptive manufacturing processes. Features include:

- Parts and assemblies scanning and measuring to determine as-built condition

- Tool paths adjustments to match actual part/assembly

- Active seam tracking

- Accommodating contour uncertainty

- Accounting for assembly manufacturing tolerances

- Automatic calibration

- Advanced part verification

- Capability of detecting and measuring part defects

- Automatic tool loading and unloading

Benefits of Adaptive Manufacturing and Configurable, Robotic Fixtures

An adaptive manufacturing approach helps manufacturers pivot faster within manufacturing processes, improve product quality, control costs, and leverage resources better.

Read more about PAR’s approach to adaptive manufacturing.

Configurable, robotic fixtures are one important solution within a flexible or adaptive manufacturing approach. Robotic fixtures provide effective means to support a variety of parts for processing in a system. By supporting families of parts, robotic fixtures can:

- Reduce the need for storage and maintenance of dedicated tools.

- Eliminate costs of multiple dedicated tools

- Save time associated with dedicated tools.

- Eliminate lead time associated with new tools or modifications.

- Reduce safety risks from handling heavy and awkward tools.

- Eliminate tool damage from handling and storage errors.

- Provide easy accommodation of design changes and introduction of new parts, without the cost of new tools.

- Maintain quality with effective processes and adaptive manufacturing techniques

Proven strategies & techniques for tackling manufacturing challenges.

PAR has developed various adaptive manufacturing strategies that utilize various patented techniques to enable the production of critical components and assemblies with exacting tolerances despite uncertainties of location, size, contour, and other factors. From mapping as-built conditions and morphing tool paths to match, utilizing integrated process heads, to robotic and configurable fixtures. When the magnitude of the uncertainty is larger than the tolerances required, PAR patented techniques and optimized system designs provide the solution for automating the manufacturing process.

"We focus on automation so our customers can focus on the aircraft."

Jim C.

Chief Engineer, PAR Systems