Decontamination & Ablation

PAR Systems designs and builds decontamination and ablation systems for removing coatings, debris and residues on parts and materials.

Our engineering experts have decades of experience with accurate ablation technologies and motion systems. We use a robust system design and highly reliable components to deliver high precision solutions designed to meet the specific tolerances for your application at maximum productivity levels.

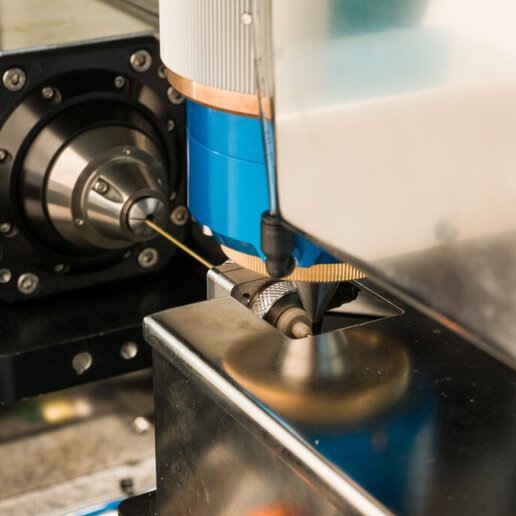

Micro Precision to the Thousandths of an Inch

How precise can we get? We can remove coatings as thin as a thousandth of an inch without damaging the wire below.

PAR can integrate multiple lasers into a single system to meet dimensional and edge quality requirements. If you need to ablate multiple sides of a part at once, we have a beam path design solution for that. Our wire-handling machines can spool to spool, cut to length, and perform wire handling options all in one integrated system.

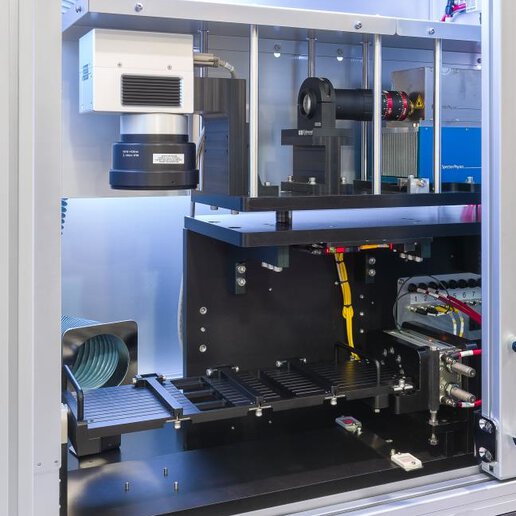

Designing for the Toughest Laser Challenges

We don’t limit ourselves to what we’ve done before. We are problem solvers and are willing to find a solution to your laser challenges. You may be searching for a laser that can process difficult materials and might not be able to find a commercial solution. PAR can design a laser solution for you.

PAR’s team has expertise in automating any laser processes and our team can help navigate to the right laser solutions for your applications.

The PAR Advantage

Industry-leading engineering.

Why should you trust PAR for a laser decontamination or ablation system? We have decades of automation and laser integration experience, along with impressive engineering talent. We have expertise in developing ablation systems using a variety of technologies including FlashJet, laser ablation, CO₂ blasting and plasma. We have a state-of-the-art facility and we work with many of the largest medical device manufacturers and we are ISO9001 and 13485 certified to meet the most stringent quality standards.

Related Laser Technologies

Our expertise shows in each element we craft.

The PAR Advantage

With decades of experience, we have established ourselves as experts in laser integration and processing. We have fostered trusted partnerships across the laser industry, and we use our expertise to design and implement customized, automated laser integration solutions for our customers.

Through our worldwide service organization, we also offer dedicated support from a team of local field service engineers, and our global consulting team can resolve the most complex engineering challenges.

Certified in all the right places.