Adhesive Dispensing

PAR Systems designs automated adhesive dispensing systems that ensure precise, efficient sealant application to meet the most stringent requirements.

PAR designs automated liquid dispensing systems that address the many challenges presented by sealant application processes. Key features and technologies of these systems provide automation and adaptability that ensure highly precise and consistent sealant application. These automated systems provide the precision necessary to meet the most stringent requirements and create monumental efficiencies.

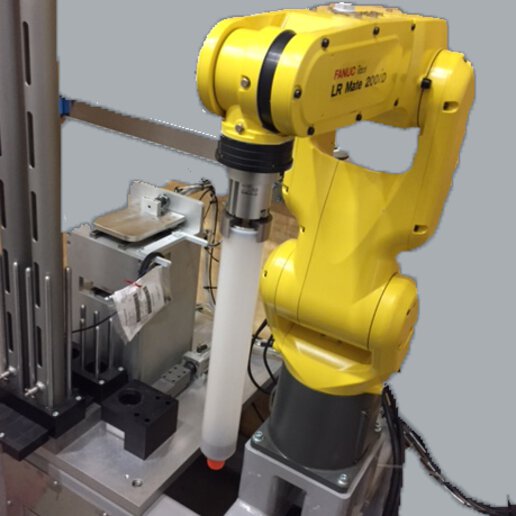

Whether configured as a single robot with auxiliary axes, or as multiple cooperative robots, our automated sealant and adhesive systems can include active seam tracking, integrated process controls, automated calibration and part localization, and more.

Features of PAR Automated Adhesive Dispensing Systems

- Servo dispenser

- Application of varying sealant beads

- Disposable fluid path modules

- Family of disposable nozzles and brushes

- Brush modules

- Robotic and rail motion systems

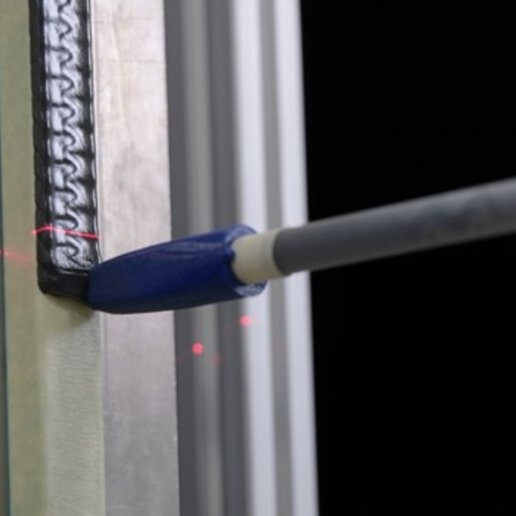

- Dispensing end effectors with laser scanners

- Automatic exchange and management of nozzles and cartridges

- Cartridge management systems or mix-on-demand systems

- Tailored solutions to support custom needs

Key Feature: Sealant Applications via Pre-mixed Cartridges or Mix-on-Demand

PAR’s end effectors have interchangeable components to automatically configure for different sealing tasks. Our end effector units can dispense using either pre-mixed cartridges or mix-on-demand (in-line mixing).

If your application uses pre-mixed frozen cartridges, PAR has an automated Cartridge Management System to ensure your thawed cartridges are automatically delivered to the robot just in time for dispensing.

Supporting Technologies

- Patented Adaptive Manufacturing/Artificial Intelligent CAM and parts management

- Real-time seam tracking and process control

- Real-time post dispense and cure inspection

- Safe error and fault handling

- Automated calibration, part localization, nozzle exchange, tool exchange, tip management, and tool and nozzle identification

Benefits of Automated Dispensing

A major challenge for sealant applications is getting the sealant in those hard-to-reach places. To meet these challenges, PAR has specially designed nozzles and tips available. Our team can tune your system with the appropriate specially designed nozzle, so it meets your specified dispensing performance and robotic motion. This ensures a consistent application, avoiding the errors that are commonly made with a manual process.

Our automated adhesive dispensing systems have a number of benefits, including:

- Significantly improves quality and consistency, while reducing costs

- Configurable fixturing eliminates the need for restraint fixtures and accommodates families of parts at reduced cost

- Capable of handling the many challenges created by variabilities associated with sealant applications

- PAR’s disposable fluid paths dramatically reduce cleaning requirements, maintenance time and costs

Our capabilities are many, our experience is deep.

The PAR Advantage

With decades of manufacturing automation experience, PAR has expert process knowledge and can deliver automatic glue dispensing machines that meet your stringent quality control requirements. Our techniques and technologies solve the many challenges created by variabilities that occur in sealant applications. This proven process provides a highly efficient and precise adhesive application that is customized to your specifications.

Through our worldwide service organization, we offer dedicated field service engineering support and a global consulting team, who can resolve the most complex engineering challenges.