Small Parts Precision Handling

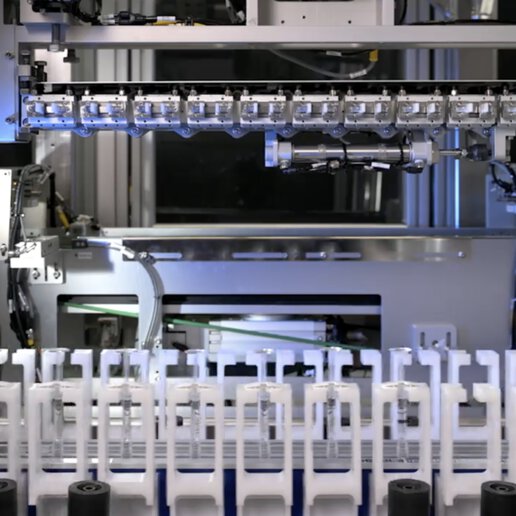

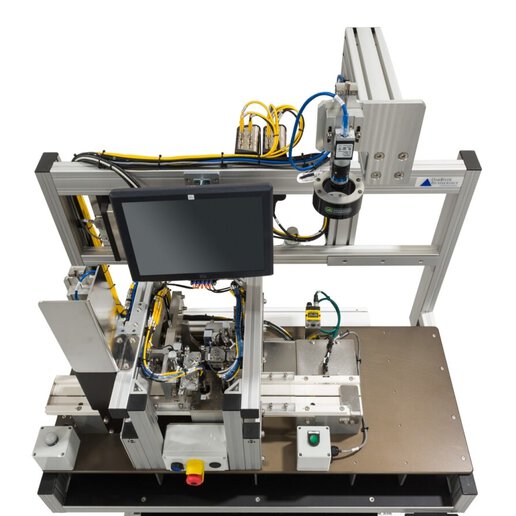

At PAR Systems, we leverage decades of experience in the design and implementation of micro parts precision handling systems. We create solutions that are suited to the unique challenges of medical device manufacturing and any other small parts handling applications.

From component feeding, laser processing and ablation, welding, to micro-dispensing, inspection, and assembly, we have designed custom systems that integrate multiple solutions to create holistic, highly precise systems for a variety of small parts manufacturing applications. We excel at applications with extremely small components and high accuracy requirements, such as spheres smaller than 300 microns in diameter placed within 5 microns of positional accuracy.

PAR Capabilities and Applications for Micro Parts Precision Handling

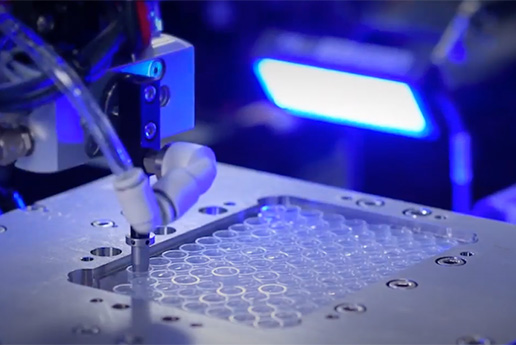

Component Feeding

PAR’s extensive experience using tray, bowl, step, and flex-feeding techniques optimizes the presentation of difficult to handle components in the assembly process. We can create multiple feeding solutions on a single system to handle unique components. In one instance, we were able to use flex feeding and robotic pick-and-place to move 350-micron outer diameter rings into a weld nest.

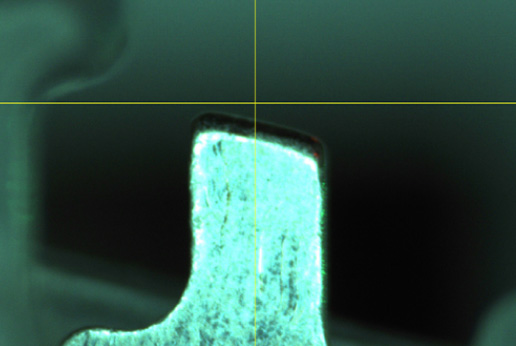

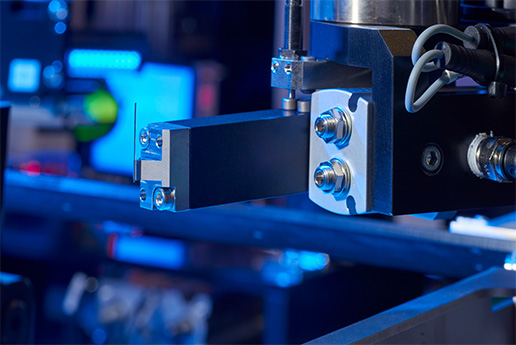

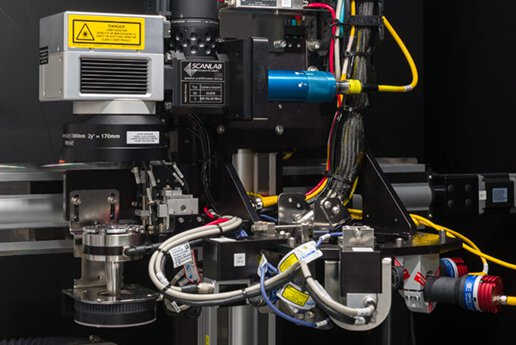

Laser Processing and Ablation

Laser processing solutions are one of PAR’s core competencies. We provide a productized approach and deliver highly customized solutions that are designed around your needs. We offer flexible, configurable laser platforms that perform ablation, welding, cutting, and more. Laser ablation for surface treatment applications is often more accurate and faster than traditional treatment methods, making it especially suitable for small parts handling applications. In one case, our systems performed the feeding, ablation, and cutting to length of 20-micron platinum iridium wire.

Forming and Heat Setting

Our methods of mold forming enable precise replication of complex geometries, which ensures consistent quality and dimensional accuracy in the produced components. Our heat setting solutions provide a controlled and uniform heat distribution, which effectively anneals, hardens, or tempers the components. This heat setting control results in improved material properties such as strength and hardness.

The PAR Advantage

Certified in all the right places.