Friction Stir Welding in the Aviation Industry

Friction stir welding (FSW) is an advanced joining process that welds high-strength alloys together. Friction stir welding in the aviation industry, in particular, is used to address a key priority–to reduce the weight of planes while delivering the same or better technical performance. Not only does friction stir welding of airframe structures reduce the weight of a plane by eliminating the need for rivets or additional joining material, it is also a cost-effective and highly-efficient joining process.

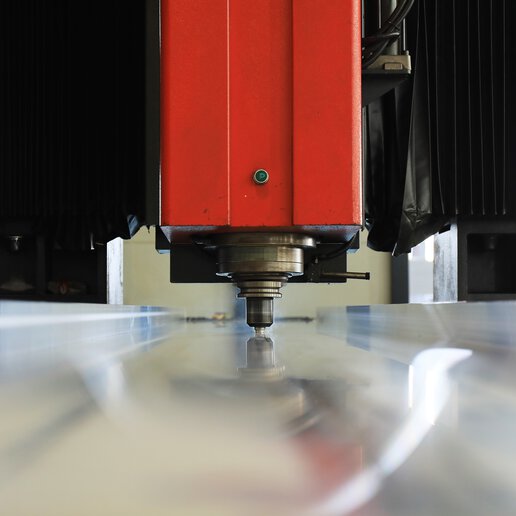

Friction stir welding is a type of welding that uses frictional heat to join parts together in their solid state–that is, without reaching the materials’ melting point. The comparatively low temperature produced is both energy-efficient and prevents the workpiece from warping or shrinking during the welding process. The metal is plasticized and joined together at the molecular level, resulting in a very strong, high-quality weld.

FSW has been widely adopted in the aeronautics industry for joining high-strength aluminum alloys that were previously considered unweldable. After historical success in the space and defense industries, the Federal Aviation Administration (FAA) approved FSW as a joining process for commercial aircraft. FAA approval has allowed the commercial aerospace industry to take advantage of cost savings through part count reduction, improved material buy-to-fly ratios (BTF), faster production times, and an environmentally friendly process that doesn’t require consumables.

How Friction Stir Welding is Used

Using FSW to join aluminum alloy stringers to wing skins and fuselage structures significantly reduces weight by eliminating material overlap and thousands of rivets. A leading aircraft manufacturer estimated weight savings of up to 1 kilogram per meter by substituting rivets with friction stir welding!

The first application of friction stir welding in commercial aerospace was by a US-based jet manufacturer that joined airframe structures without the use of rivets. PAR Systems partnered with the customer to design and build a custom friction stir welding gantry system capable of welding an entire aircraft frame in only 8 hours. The continuous weld improved structural rigidity while reducing weight of the jet. By replacing 60% of rivets with friction stir welding, assembly times were 10X faster. The computerized control of the FSW process created accurate and repeatable welds, virtually eliminating time-consuming rework.

For this manufacturer, using FSW to construct their airframes saved over 16,000 hours of labor that directly impacted the affordability of the aircraft.

Aeronautical Benefits of Friction Stir Welding

Big Opportunities for Cryogenic

Fuel Tanks

FSW provides a practicable opportunity for the safe use of hydrogen fuel in the commercial aerospace industry. Creating cryogenic tanks with solid state joining results in no rivets or gaskets, creating a gas tight seal without leakage for the long term (as demonstrated in collaborative research done between Boeing and NASA). In addition, fewer welding defects, improved material properties thanks to friction stir processing and additive manufacturing, improved stability, and lower residual stresses produced with FSW improves the corrosion resistance of cryotanks.

Additional applications for FSW in the aeronautics industry include the production of:

- Fuselage panels

- Wing skins and wing ribs

- Chord supports

- Body skins

- Bulkheads

- Aircraft floors

- Structure assemblies

- Beams

- Electronic enclosures

- Air tanks

- Kerosene- and naphtha-type jet fuel tanks

Replace Rivets to Reduce Weight and Part Count

FSW replacement of rivets gives the structure a solid continuous joint with more structural rigidity and reduced weight. A leading aircraft manufacturer estimated weight savings of up to 1 kilogram per meter by substituting rivets with friction stir welding!

FSW joints can eliminate rivets in plate-stringer configurations and eliminate rivets and overlapping material in overlapping plate joints by friction stir welding a butt joint.

Reduction of Raw Materials

The buy-to-fly ratio is used in the aerospace industry to describe how much material is wasted in a manufacturing process. By definition the BTF ratio is the weight of the raw material purchased divided by the weight of the final part. Joining two pieces of material using FSW significantly lowers the BTF ratio compared to subtractive manufacturing processes like milling where the BTF ratio is often higher than 10- meaning only 10% of the material purchased remains in the final part.

Improve Structural Integrity & Reduce Parts in Floor Panels

Pressurized structural panels have a long assembly process that requires many fasteners and components. Using FSW to join parts reduces assembly time and parts processing- while creating a reliable bond that stands up to the forces and durability of flight. Because molecules are actually stirred together, FSW creates a much stronger bond and longer life than rivets or traditional fusion welding.

In Process Quality Assurance

With a friction stir welding solution designed by PAR Systems, key process parameters and machine feedback are recorded. These valuable insights have enabled customers to avoid post-weld x-ray or ultrasonic testing.

Design, Manufacturing and Operational Benefits:

Weight Savings

Through the elimination of rivets, fasteners, and sheet-overlap designs.

Join New Alloys

Previously unweldable aluminum alloys are 1/3 the weight of steel.

Higher Reliability

Higher strength and improved fatigue performance compared to riveted joints.

Environmental Benefits

Reduced environmental hazards, energy usage and waste.

Reduced Fuel Consumption

Weight savings up to 1 kg per meter of FSW means flying farther while decreasing costs.

Lower Maintenance Costs

Through more robust parts and easier testing.

Extended Part Life

Superior weld strength and corrosion resistance results in higher quality welds.

Easy Recycling

Save time when no deconstruction or sorting is required to recycle entire parts of a single material.

The PAR Advantage

At PAR Systems, we understand the priorities of the Aviation industry, and design and build custom friction stir welding systems to better service those priorities. Our patented I-STIR technology can achieve superior quality welds with the potential to minimize or eliminate post-weld inspection. We also provide production software to manage weld schedules, real-time execution, and data acquisition and storage. Visit our friction stir welding page to learn more.