Friction Stir Welding

PAR Systems designs and develops friction stir welding (FSW) machines using I-STIR™ FSW technology–the most advanced friction stir welding technology on the market. Our FSW machines are built for our customers’ needs and allows them to take full advantage of FSW process benefits.

Take full advantage of Friction Stir Welding with I-STIR™ Systems

Friction stir welding offers:

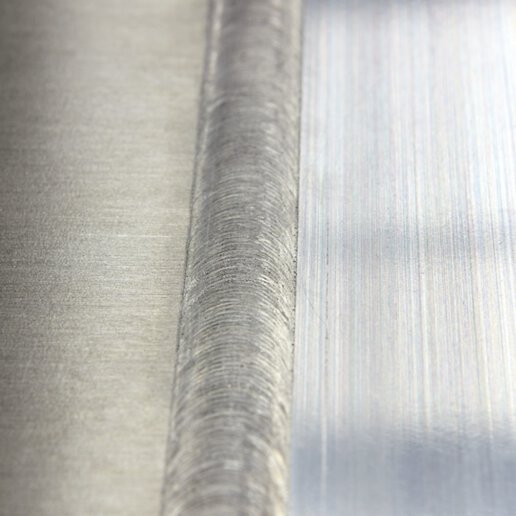

- Superior mechanical properties in the as-welded condition as compared to other joining technologies.

- Minimal distortion of joined parts compared to other joining technologies due to welding at temperatures below the melting point.

- Ability to easily weld joint geometries and complex curvatures.

- Ability to weld materials less than 1mm and greater than 75mm thick in a single pass.

- Welding of previously “un-weldable” alloys or dissimilar alloys.

- Improved safety, easy automation, and lower setup costs.

- Environmentally friendly and energy efficient–no filler material, shielding gas, or harmful emissions.

PAR’s FSW best-in-class technology:

- Incorporates independent forge and/or pin actuators with five or more degrees of freedom.

- Includes strategically incorporated sensors and a high fidelity data acquisition system that allows customers to achieve superior quality welds with the potential to eliminate post-weld inspection.

- Includes 3 modes of FSW for maximum application flexibility (i.e., fixed-pin, adjustable-pin, and self-reacting).

- Manages weld schedules, real-time execution, and data acquisition and storage production software.

- Includes world-wide support with local field service engineers.

What you need to know about friction stir welding

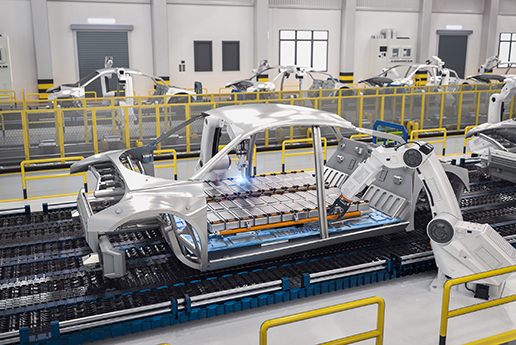

Friction stir welding (FSW) is a solid-state joining process that uses a rotating, non-consumable tool to generate frictional heat to join materials. Friction stir welding is a proven and advantageous technology in many industries including aerospace and defense. FSW is often chosen because of its superior weld quality, however, the speed of the welding process is increasingly becoming a valuable benefit.

There are many factors that will impact your friction stir weld including pin tool design, weld parameters and accuracy, spindle speed, part clamping. It is important to know what these factors are and consider them before finalizing the design of your friction stir welding equipment to achieve the best result. PAR will help you navigate these factors and build a solution right for you with our I-STIR™ FSW technology.

Why I-STIR™ Technology

PAR’s FSW machines in combination with our advanced control system allows customers to take full advantage of the process benefits while allowing the ability to deploy technology for large, complex applications.

PAR has highly-instrumented, high-fidelity solutions and a flexible control system tailored for process control and monitoring in a variety of motion systems. The combination makes PAR’s I-STIR the most advanced friction stir welding solution on the market.

Comprehensive development model

PAR has a deep understanding of complex FSW processes and FSW tooling. We employ an inter-organizational team approach and progressive three-phase program—process development and feasibility study, full development of requirements, and project build and execution—to put FSW into production as efficiently and cost-effectively as possible. The I-STIR phased program is based upon a best practices model developed through decades of producing complex, turnkey systems.

Unrivaled process control

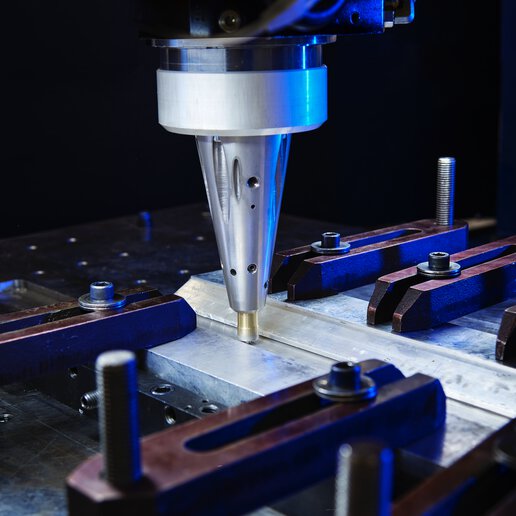

Maintaining optimal pin position, especially in nonlinear applications, is critical to producing consistent, high-quality FSW joining. As a pioneer and leader in precision force and motion control, I-STIR technology incorporates innovative mechanical, electrical, and software systems to deliver unrivaled control over all aspects of friction stir welding processes.

Advanced FSW fixturing and tool design

I-STIR technology drives the state-of-the-art of FSW tooling with innovative pin tool and forge load control technologies. PAR has developed the ability to precisely control forge and pin loads in our design and control concepts for complex curvature.

Worldwide FSW Leadership

I-STIR technology plays a leading role in fostering the worldwide development of FSW through numerous collaborations with experts in friction stir welding industry, government, and academia including University of South Carolina, Lockheed Martin, and the Institute de Soudure.

We have also secured several U.S. patents of leading edge FSW technologies including self-reacting welding head, co-exclusive NASA license for adjustable pin tool, and independent forge actuator.