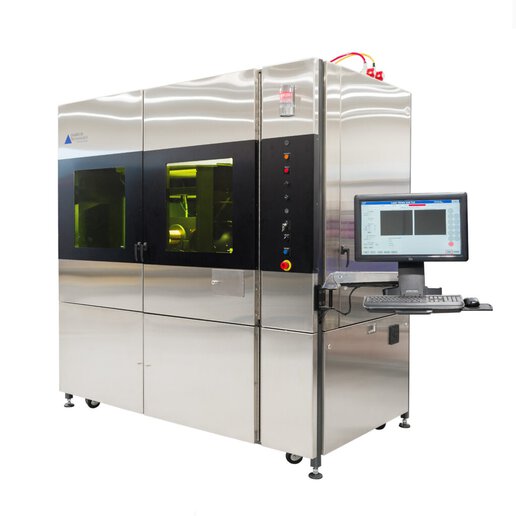

Cutting & Welding Automation Solutions

We have the experience to support your laser cutting and welding process and can integrate your unique application within a total automation solution.

We consider lasers as a technology or component within a complete solution—like a robot, a precision servo stage, a camera, or any other core element of an automated process. Our customers define the system requirements and we develop a total system to solve the need.

Laser integration is a core competency in our process automation offerings. We can deliver cutting-edge technology that makes your operation more efficient and effective.

Comprehensive Experience in Cutting, Welding, Material Variety, and System Needs

PAR can cut and weld a wide variety of materials from thick to thin, metallic to non-metallic and complex surfaces. We are experts at substrate materials, both metals and non-metals and challenging materials such as silicones. We are familiar with very small product features to very large material features. Our team can also perform in-tool inspections with integrated cameras.

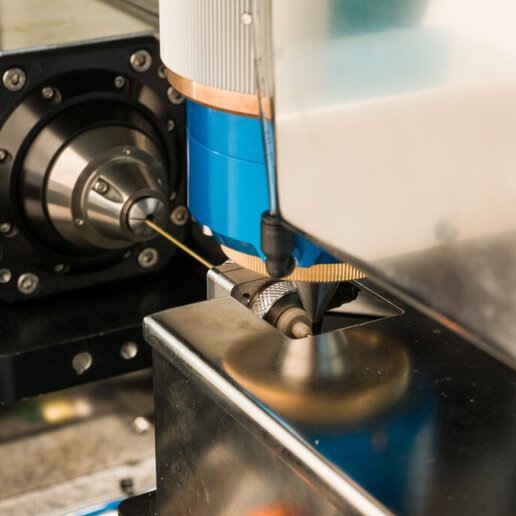

Laser Cutting

Automate your process

PAR’s laser cutting machines automate cutting with high accuracy. Automatic calibration guarantees accurate tool tip motion over the entire part envelope. Our stabilization system is designed to ensure the stability of the component while materials are being cut. PAR’s integrated process head minimizes the distance between the laser and the tool tip, eliminating the need for complex beam delivery and maximizing accessibility for maintenance.

Laser Welding

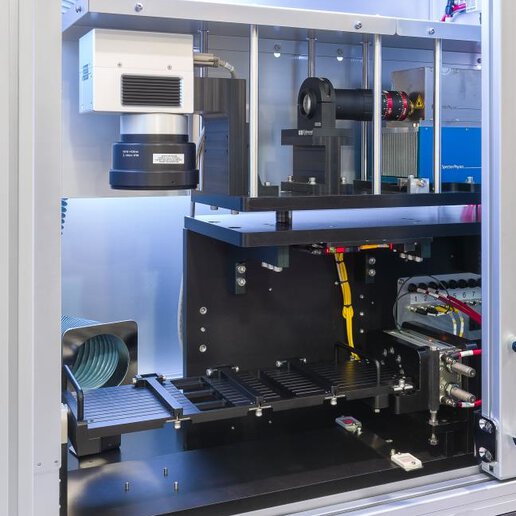

Integrating multiple technologies.

We integrate a wide variety of capabilities into our laser platforms. On top of many different laser types, these systems may have vision, galvos, part feeding, fixture handling, conveyors, and more.

Related Laser Technologies

Our expertise shows in each element we craft.

The PAR Advantage

With decades of experience, we have established ourselves as experts in laser integration and processing. We have fostered trusted partnerships across the laser industry, and we use our expertise to design and implement customized, automated laser integration solutions for our customers.

Through our worldwide service organization, we also offer dedicated support from a team of local field service engineers, and our global consulting team can resolve the most complex engineering challenges.

Certified in all the right places.