Automated Assembly

Component Feeding

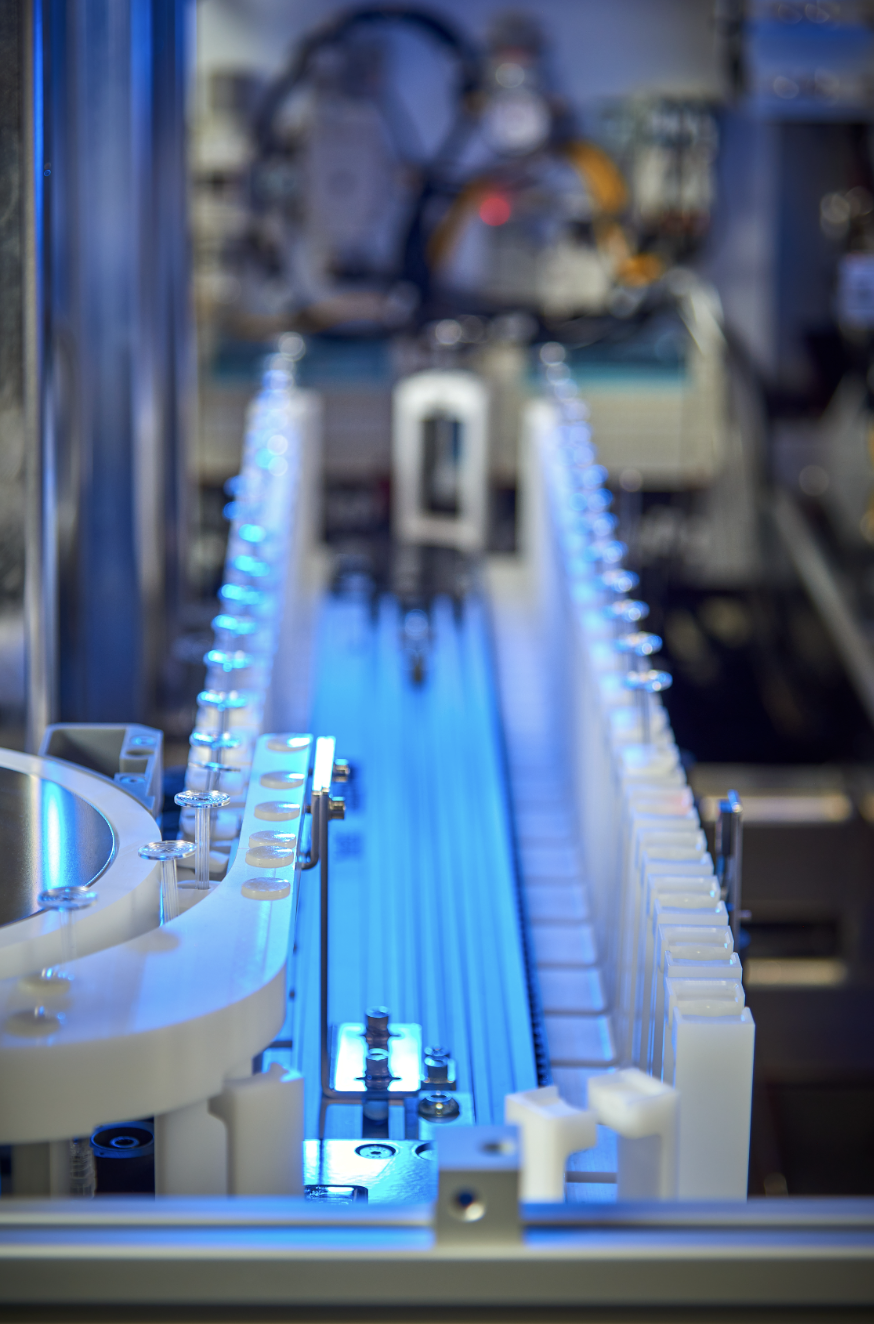

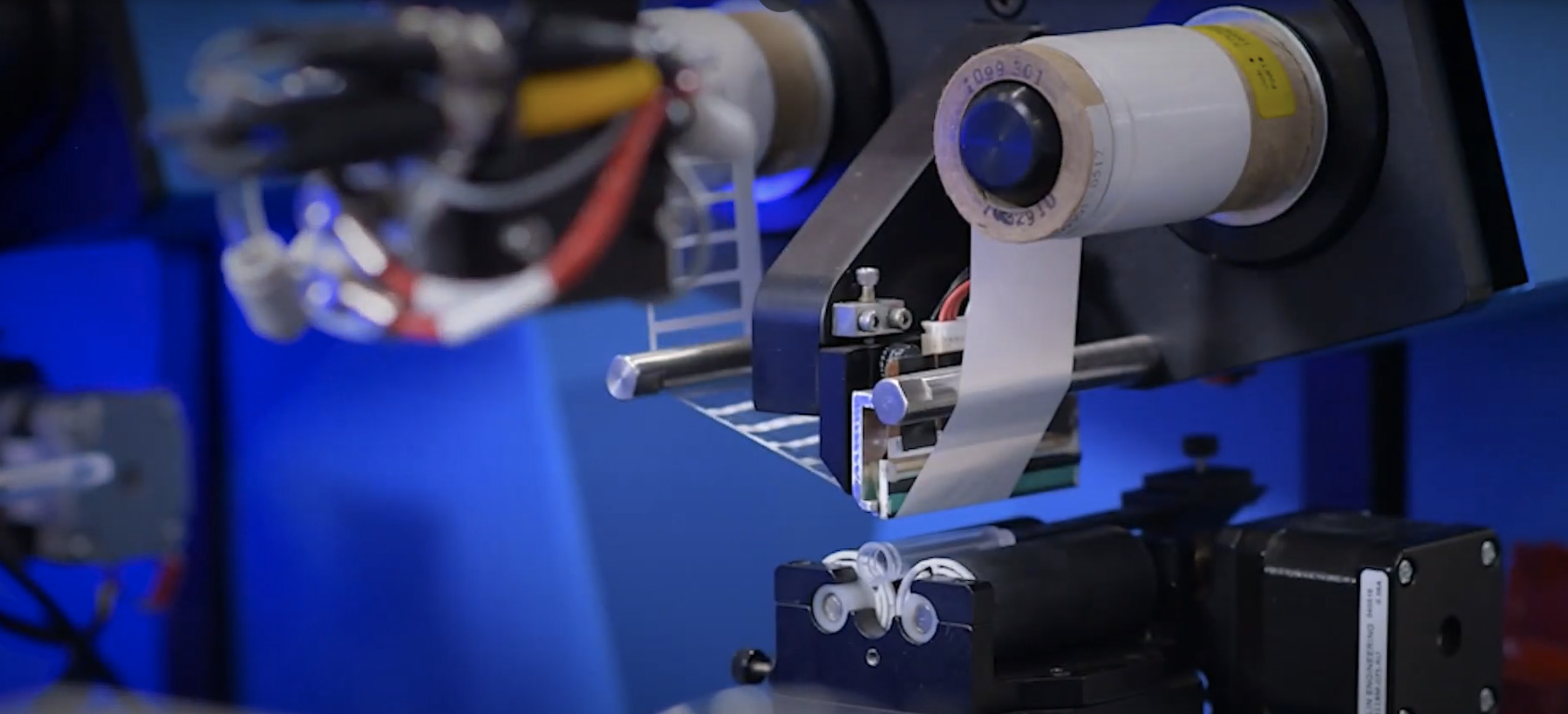

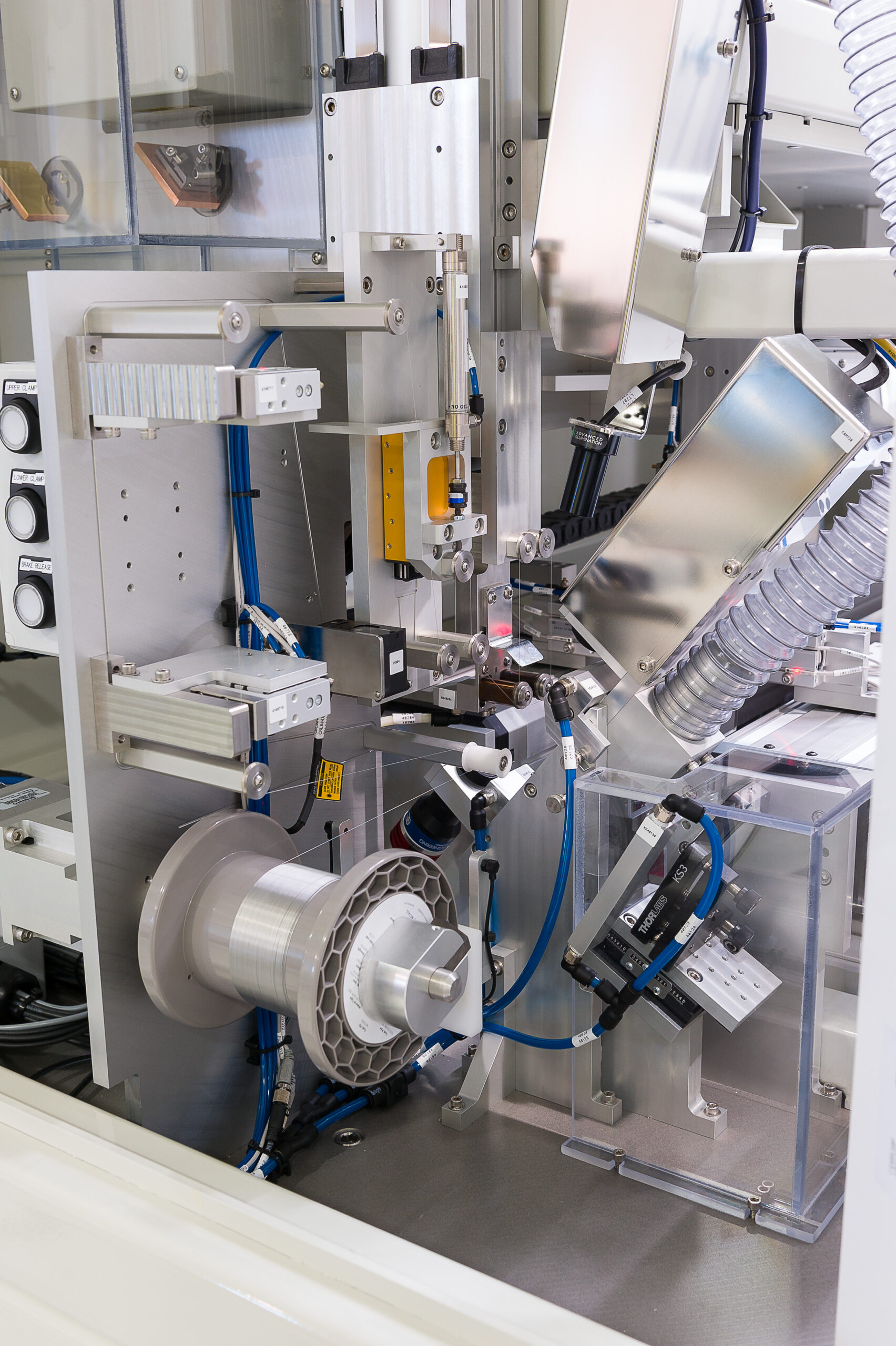

Component feeding is often a core function of assembly automation and one that PAR Systems specialize in. Our automated feeding capabilities include material and parts feeding, web and wire handling, and flex feeding.

PAR’s extensive experience using bowl, step, and flex-feeding techniques optimizes the presentation of difficult to handle components from bulk in the assembly process.

Efficiency starts with automated feeding

Material and Parts Feeding

Flex Feeding

Wire Feeding

Web Handling and Winding

The PAR Advantage

Automated component & part feeding experience:

We automate the handling of components from very small precision parts destined for medical devices to very large parts destined for rockets and for many things in between. We also have capability to automate component and part feeding amongst a wide range of materials.

Put cutting-edge technology to work for your operation.

See how our clients have leveraged our commitment to precision.

Our whole team had such a positive experience with you and your company. Your investigation was critical to leading us to the base component.