Laser Platforms

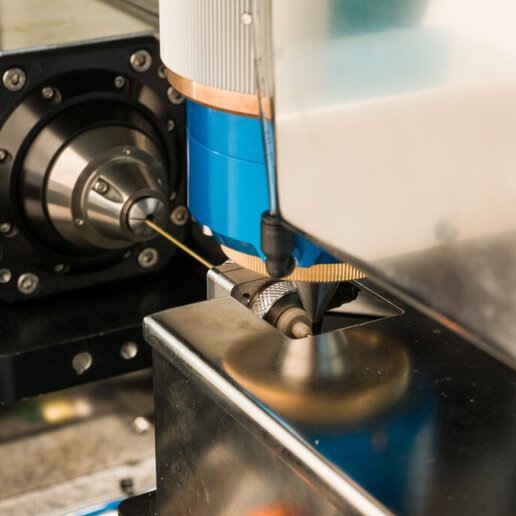

Laser platforms from PAR Systems are designed to provide a flexible and reliable solution for a variety of laser processing applications–including cutting, drilling, welding, ablation, marking, and milling.

Our laser platforms are designed to be flexible, easily configurable, and reliable in order to meet the needs of specific applications. Our platforms have the flexibility required for research and development (R&D) applications along with the reliability demanded in production settings. These platforms support a broad spectrum of laser types, including TEA, UV, CO2, Fiber, Femto, and more.

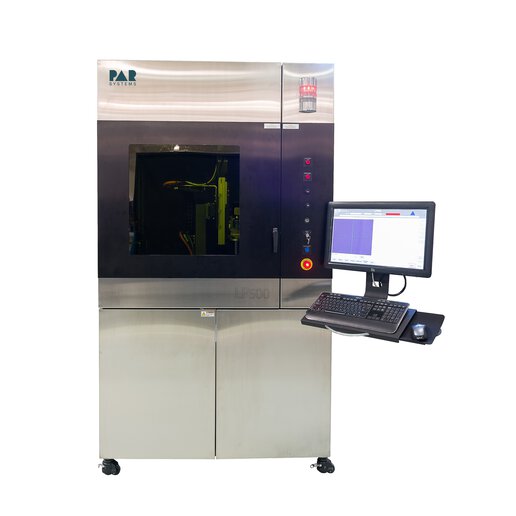

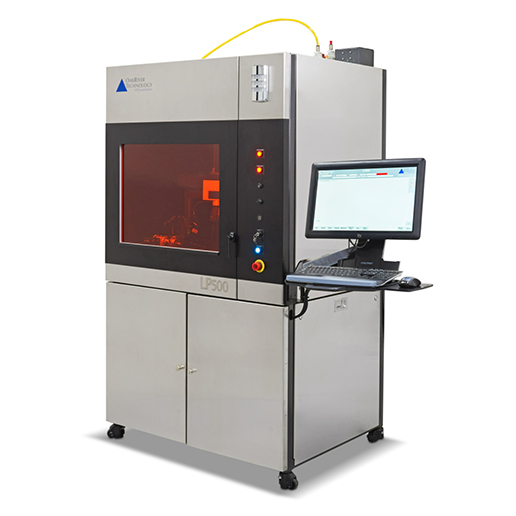

LP500 Laser Platform

The LP500 Laser Platform provides a flexible CDRH Class 1 laser platform for many of your laser processing needs. It is easily configurable to accommodate your specific application(s) with customizable product fixturing. The simple drag-and-drop programming interface provides a no-code development platform that allows users to quickly and confidently develop programs. The LP500 is manufactured with proven industrial-grade components to deliver a robust and reliable solution.

Key Specifications of the LP500:

- Configurable with 1-5 axes of motion

- Graphical interface allows users to easily develop custom sequences for their process

- 40+ configurable commands define product fixturing, manage motion profiles, prompt users for input, access vision tools, control laser output, and more

- Pulse Shaper allows the development of customized laser pulse profiles and emission sequences

Watch this video to see the LP500’s intuitive interface and processing in action.

LP50 Laser Platform

The LP50 takes the configurability of customized product fixturing and simplicity of no-code programming and wraps it into a more compact, tabletop package. The LP50 continues to be manufactured with proven industrial-grade components to deliver a robust and reliable solution.

Key Specifications of the LP50:

- Configurable with 1-3 axes of motion

- Graphical interface allows users to easily develop custom sequences for their process

- 28 configurable commands define product fixturing, manage motion profiles, prompt users for input, access vision tools, control laser output, and more

- Pulse Shaper allows the development of customized laser pulse profiles and emission sequences

The PAR Advantage

At PAR, laser integration is one of our core competencies. We have trusted laser partners across the industry, and we work with all major laser manufacturers to facilitate early-stage process development. Our laser platforms are the method by which we provide flexible, configurable solutions to bring automation to new or existing processes.

Through our worldwide service organization, we also offer dedicated support from a team of local field service engineers, and our global consulting team can resolve the most complex engineering challenges.

Our expertise shows in each element we craft.

"High quality systems and excellent systems integration. Better than others I have worked with."

Mfg. Engineer

Leading Medical Device company

Certified in all the right places.