Automated Fastening & Defastening

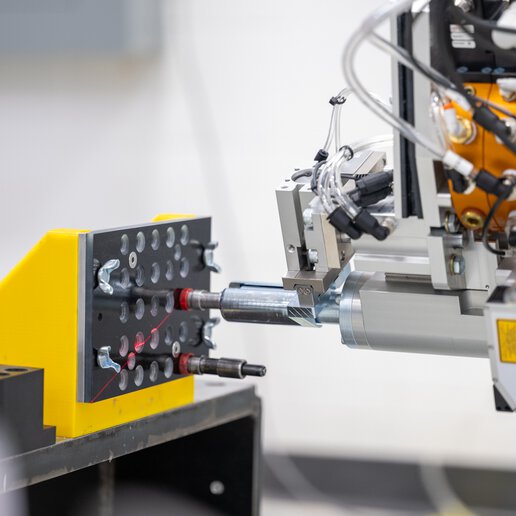

PAR Systems designs and implements automated fastening and defastening systems that allow for accessibility in challenging applications while providing high quality installation.

Advantages of Automated Fastening Systems from PAR

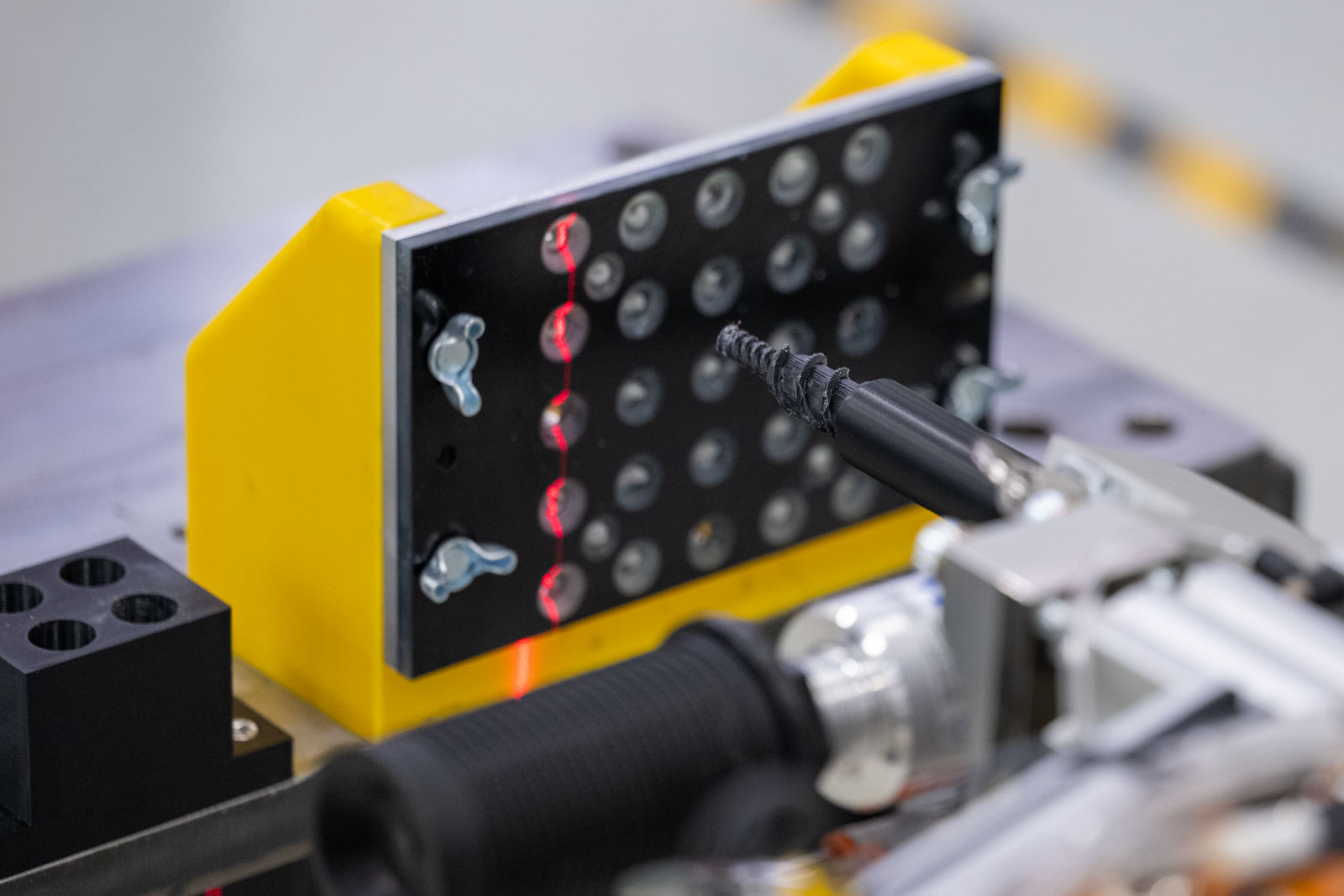

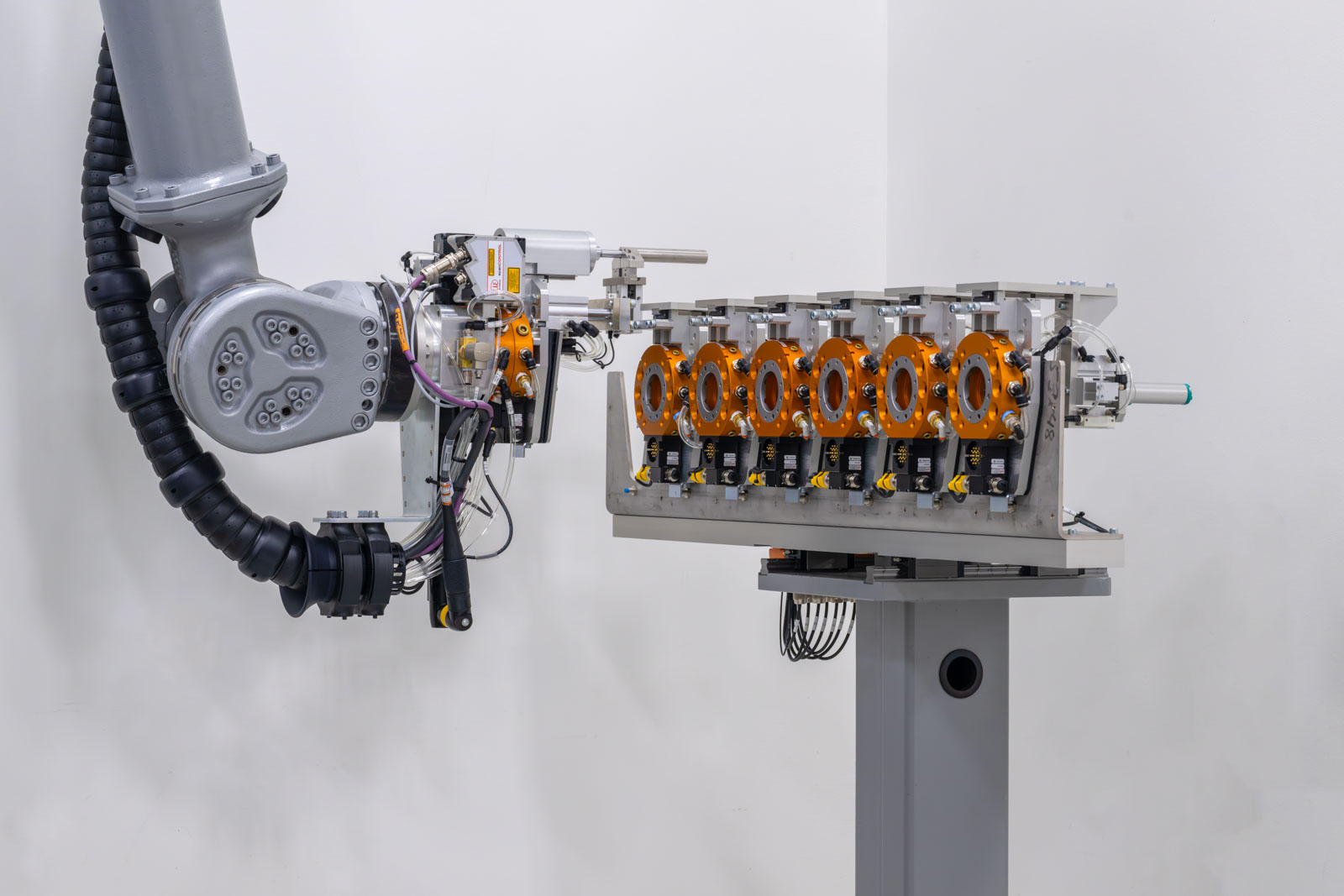

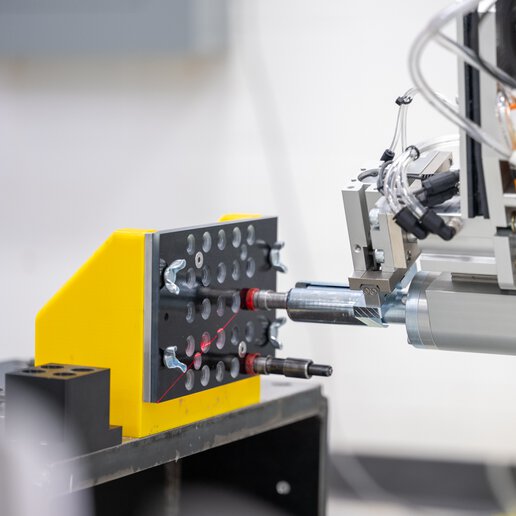

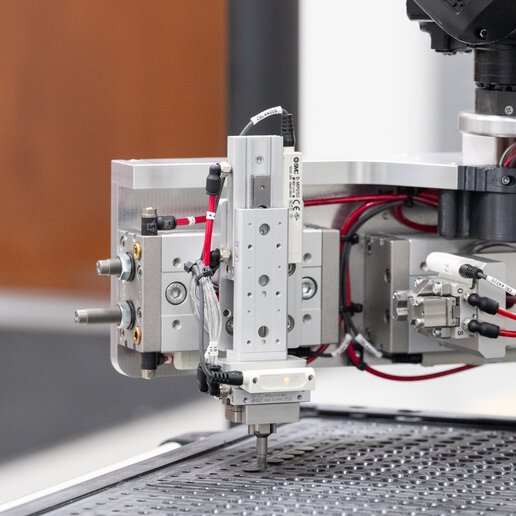

PAR integrates proven tools into automated end effectors along with appropriate sensors and intelligence to perform as a fully automated precision fastening system. Systems may include multiple cooperative robots or single sided motion systems with C-style end effectors for work along edges.

Technical features of our fastening systems:

- Two-sided (nut and bolt) fastening (spin, align, fastener vector, engage bit onto fastener)

- Fastener delivery, handling, and preparation activities

- Hole clearing

- Stack thickness measurement

- Application of sealant to fastener prior to insertion

- Enabled auto-loading of fastener ship-sets

- Single-layer and cassette design for efficient and flexible fastener access and storage

- Maximum flexibility to adapt to variations in manufacturing specifications

- Single end effectors for two-sided fastening (both fastener and nut sides)

- Coordinated actions between multiple robots: Fastener Handling Robot and Fastener Installation Robot, as well as between Fastener Installation robots on each the fastener and the nut sides

- Adapted to off-nominal parts using adaptive manufacturing techniques

- Robust end effectors which integrate with existing tooling

Key Feature: Accessibility in Challenging Applications

PAR’s fastener installation equipment and processes allow for tools that can reach into tight areas and around obstructions. We make it possible to install fasteners where other automated fastening systems typically cannot.

Automated Precision Fastening Systems

- Significantly reduce man-hours and costs, while improving productivity

- Solve many challenges created by variabilities that occur with incoming materials

- Combine multi-function processes in a single work cell, including scanning, prepping, and painting, reducing manual operations while maximizing space on the manufacturing floor

- Optimize accessibility in confined spaces

Why Automated Fastening

Automating Defastening Processes with PAR Systems

Defastening is a critical requirement for many Maintenance, Repair and Overhaul (MRO) operations, especially in aerospace applications. Automating this process produces higher quality defastening processes and improves efficiency.

Advantages of Automated Defastening Systems from PAR

PAR develops and installs defastening systems that automatically locate and remove fasteners for wing assembly and maintenance. This same automated defastening system can then produce fastener holes in the replacement skin that correspond with the existing substructure.

The PAR Advantage

Innovation. Adaptability. Partnership.

We design, manufacture, test, install, and support all of our systems for their entire usable life. Our automated precision fastener and defastener systems are designed to be flexible for challenging applications, ensuring any fastening or defastening application can experience the benefits of fully automated operations. Through our worldwide service organization, we offer dedicated support from a team of local field service engineers, and our global consulting team can resolve the most complex engineering challenges.