Automated Joining Solutions

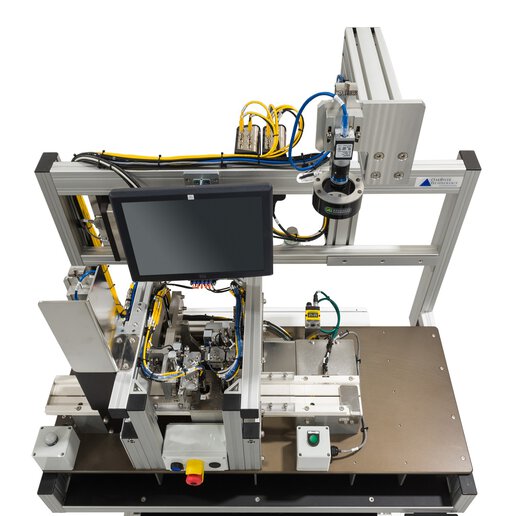

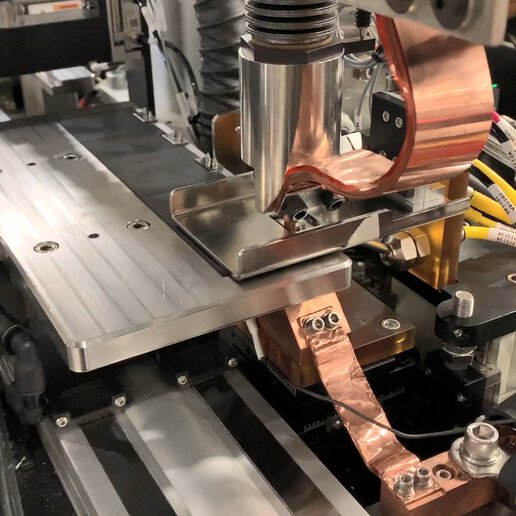

We’re experts at automating joining technologies. If you need an automated joining solution, we can design and build a joining system for your needs.

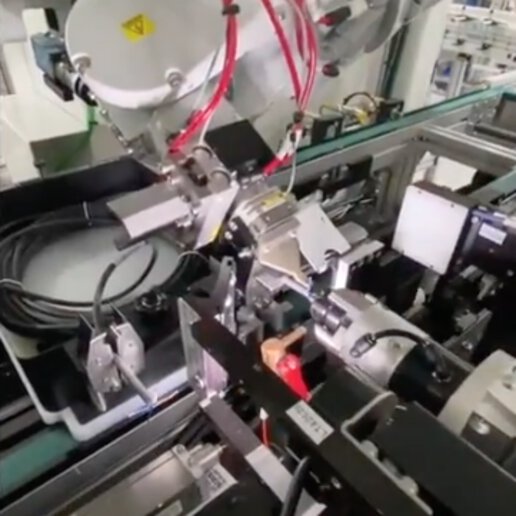

PAR Systems can automate the joining of a wide variety of materials from very small to very large, metallic to non-metallic and complex surfaces. We are experts at substrate materials, both metals and non-metals, and challenging materials such as silicones.

We have the knowledge and capabilities to help you. We have expertise with all the major joining methods and have proven our technologies of a multitude of applications and materials.

Experts at All Major Joining Methods Materials

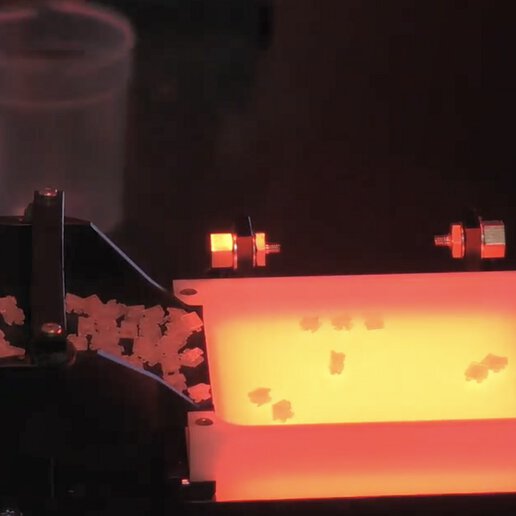

PAR can weld a wide variety of materials from thick to thin, metallic to non-metallic and complex surfaces. We are experts at substrate materials, both metals and non-metals, and challenging materials such as silicones. We are familiar with very small product features to very large material features.

- Silicone

- Plastics

- Ceramics

- Metallic

Joining Complex Paths

Put cutting-edge technology to work for your operation.

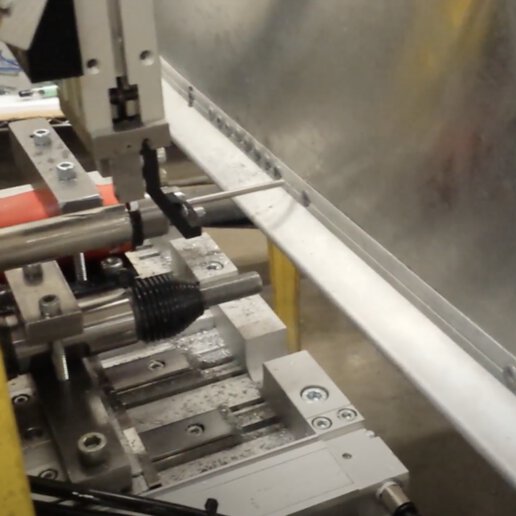

Adhesives and glues are one way to join materials together, and your manufacturing process might require it, or our team might recommend it as a joining solution. Our team can automate the gluing or adhesive application process with precision and dispense along completed paths or in fixed locations. Our systems also typically automate the curing process as well to ensure a long-lasting bond.

Joining Methods and Technology

The Par Advantage

Why PAR?

- PAR has expertise in integrating precise motion and handling of parts with automated joining techniques.

- We have the ambition to develop processes to join materials with higher precision than ever done before.

- Our expertise extends across a wide range of joining applications from sagging to welding.

Hear what our client says about our commitment to their business.

"PAR is the top consideration; we’ve built a good working relationship. They are best for maintaining and driving deadlines and communication."

MFG. ENGINEER

LEADING INDUSTRIAL SENSOR COMPANY

Certified in all the right places.