Commercial Aerospace Manufacturing

PAR Systems offers manufacturing equipment designed and built for complex aerospace manufacturing applications such as distortion-free waterjet cutting of complex parts, automated precision drilling systems, robotic configurable fixtures, and automated sealant dispensing systems.

Experts in Complex Production Needs for Aviation

PAR has long supported complex production in civil and commercial aviation manufacturing with advanced systems. Our expertise, innovation, and advanced technologies combine to create solutions that improve efficiency, productivity, consistency, and precision. Decades of experience in composite manufacturing, friction stir welding, and other technologies inform our solutions and provide exemplary results for our partners.

Highlighted Offerings for Commercial Aerospace and Civil Aviation

Waterjet Cutting

Waterjet cutting systems provide highly controlled, precise cutting of parts. This process eliminates the potential for material heat distortion. Our waterjet cutting systems operate in up to 6 axes of motion and can be customized to suit any application. We also provide fully integrated systems that include the capability to perform part geometry verification and automated part and tool loading.

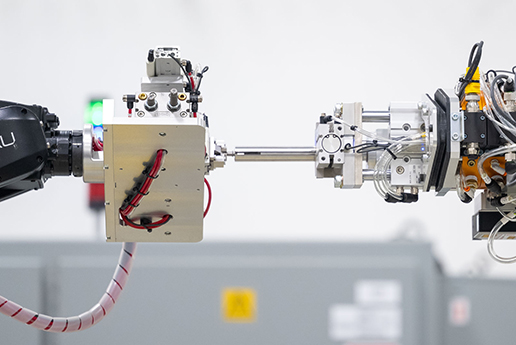

Precision Drilling

Precision drilling is critical for aerospace manufacturing. PAR offers automated systems to ensure precise drilling for determinate assembly holes, precision fastener holes, holes in wing spars and fuselage barrels, in composite skins or multiple material assemblies. PAR’s precision drilling systems include: customizable system configuration for extended work envelopes, exchangeable heads for a wide range of drilling sizes, automated tool changer and verification, and more.

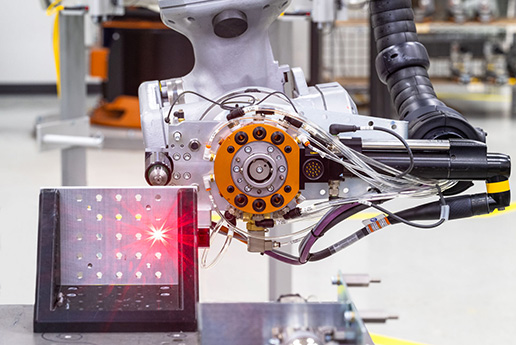

Configurable, Robotic Fixtures

Eliminate costs and reduce the time associated with the handling, storage, and introduction/removal of dedicated tools in your application. Robotic and configurable fixtures from PAR provide easy accommodation of design changes and the addition of new parts while maintaining quality, using adaptive manufacturing techniques. In one case, PAR worked with an aircraft manufacturer to create a custom fixture for a family of over 800 parts, allowing all parts to be managed within one set of robotic fixtures that remains within the machine blueprint, providing considerable time and cost savings.

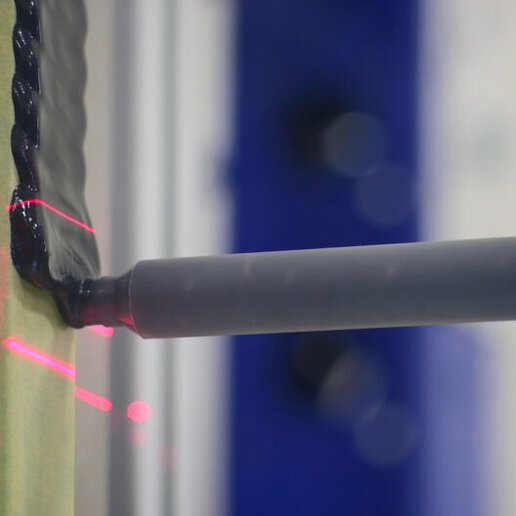

Sealant and Adhesive Dispensing

Automated sealant and adhesive systems from PAR ensure a consistent application every time and avoid the quality concerns commonly made in a manual process. Our automated systems can include active seam tracking, integrated process controls, and if required, quality verification. Our systems also can be equipped with interchangeable components to automatically configure for different sealing tasks. Our end effector units can dispense using either pre-mixed cartridges or in-line mixing, depending on the application.

Additional Aviation Manufacturing Offerings

Why PAR?

The PAR Advantage

PAR Systems offers a variety of advanced manufacturing solutions for the aerospace industry. Our waterjet cutting, precision drilling, configurable fixtures, and sealant dispense systems are all equipped with innovative, adaptive, and customizable technologies to service the unique needs of aviation manufacturing applications.

Not only that, but we continue to strive for a zero-emission flight future and use our friction stir welding technology to help our customers reach that goal.

Through our worldwide service organization, we offer dedicated field service engineering support and a global consulting team, who can resolve the most complex engineering challenges for aerospace manufacturing.

Our expertise shows in each element we craft.

Certified in all the right places.