Precision Drilling

PAR Systems designs optimal drilling solutions for the aerospace industry that are equipped with automatable features for improved efficiency and performance.

Advanced Manufacturing Techniques Increase Production Efficiency

PAR utilizes many advanced manufacturing techniques and technologies to ensure the most efficient and effective precision drilling possible.

Optimal Drilling Solutions for Aerospace Operations

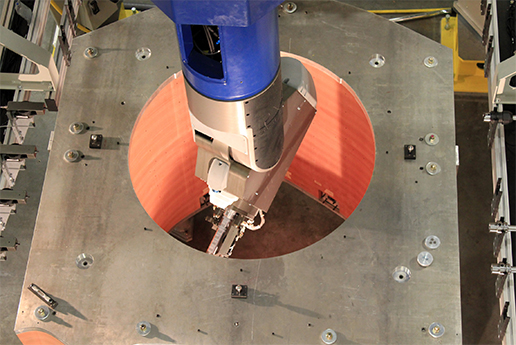

Precision drilling is a critical requirement for aerospace operations. Whether drilling DA holes or precision fastener holes, in composite skins or multiple material assemblies, PAR Systems provides optimal drilling solutions with automatable features that improve efficiency and deliver superior performance.

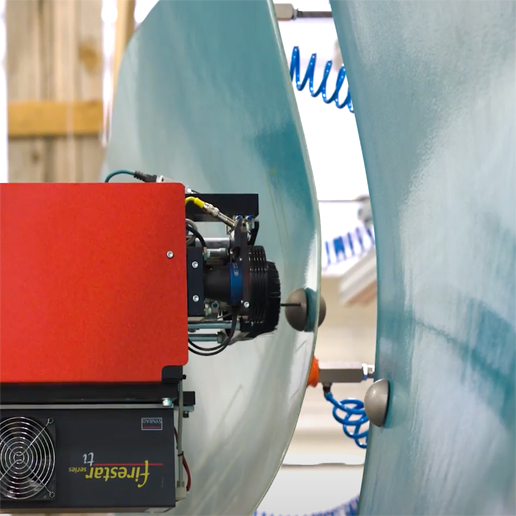

From wing spars to fuselage barrels, to flight control surfaces, PAR can provide the solution to ensure you meet your program needs.

Key Features of PAR Drilling Systems

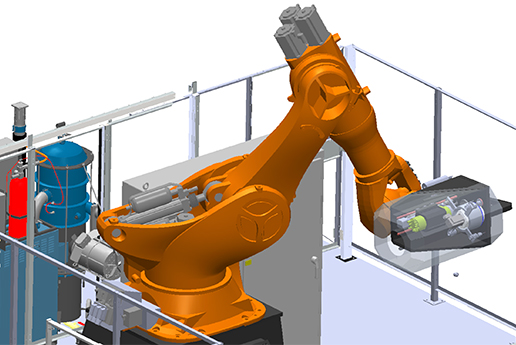

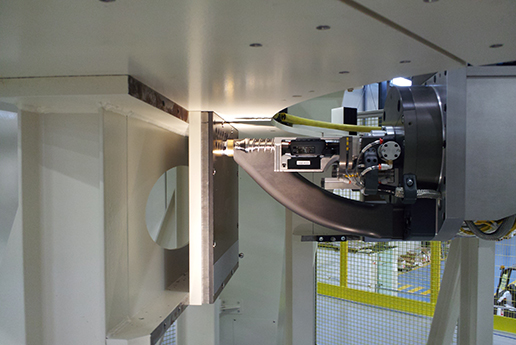

Precision drilling systems from PAR operate with spindle and laser drilling processes configured to suit the needs of your application. They are supported by advanced technologies deliver high-quality results suited to your applications. Key features of our drilling systems include:

- Accurate positioning of holes in multiple material stack-ups

- Adjusted drilling parameters (speed, feeds, etc.) based on material and material stack-ups

- Patented multifunction end effectors enable multiple operations in a single configuration

- Precision counter-sinking in metals and composites

- Automated tool loading and unloading

- Optional automated hole inspection

- Flexible fixturing and fixtureless part restraining

Precision Drilling Benefits Include:

- Customizable system configuration for very long work envelopes

- Quick tool changes for a wide range of drilling sizes, from large hole drilling to small hole drilling

- Automated tool changer, RFID tool verification, and coupon drilling for calibration

- Advanced manufacturing technologies identify “as presented” part configuration and understand part variances to create tool paths that accommodate differences from nominal model

- Multiple work stations accommodate manual operations adjacent to automated or collaborative machine operations

Why Automate Drilling?

Precision drilling is a critical requirement for many assembly operations, especially in aerospace drilling applications. Automated systems reduce manual effort, increase efficiency and offer technologies to improve production–such as inspection tools–to ensure high-quality, consistent hole drilling.

Whether drilling determinant assembly holes or precision fastener holes in composite skins or multiple material assemblies, PAR designs precision drilling systems equipped with advanced technologies to bring automation into any drilling application.

Additional Capabilities of PAR Systems Technologies

The PAR Advantage

Experience. Automation. Innovation.

PAR has decades of experience automating challenging manufacturing processes. We have an expert team of design engineers dedicated to aerospace applications, and our expertise is in custom automation systems. We design, implement, and support precision drilling systems for a variety of challenging applications, and support those systems with innovative technologies that bring automation to drilling operations.Through our worldwide service organization, we offer dedicated field service engineering support and a global consulting team, who can resolve the most complex engineering challenges for precision drilling applications.