Advanced Manufacturing Systems

PAR Systems designs, implements, and maintains advanced manufacturing systems built to produce critical components in challenging manufacturing environments.

PAR has patented approaches to producing critical components with exacting tolerances in challenging and uncertain manufacturing environments. If you produce high value products that require tight tolerances yet exhibit significant uncertainty of location, size, or contour, PAR’s advanced manufacturing systems can help.

Our automated cutting and trimming systems, robotic and configurable fixtures, high-precision friction stir welding solutions, and expert consulting and service provide solutions for the most challenging applications–from design, to implementation, production, and maintenance.

Our Systems

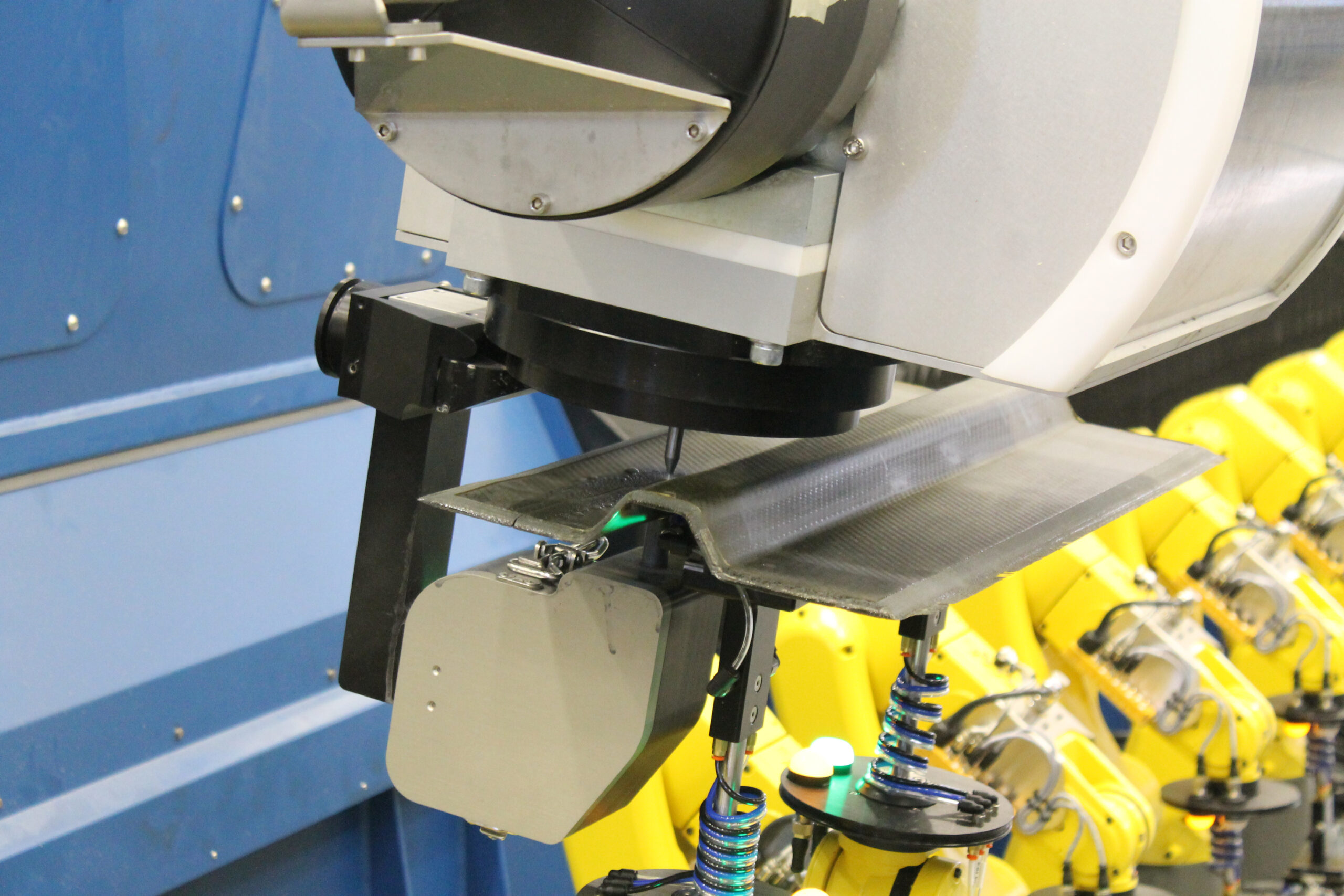

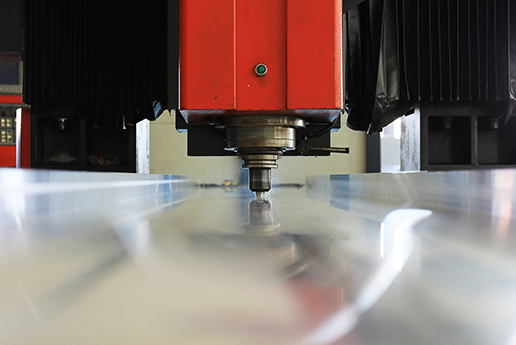

Cutting & trimming

Customized to improve quality & productivity.

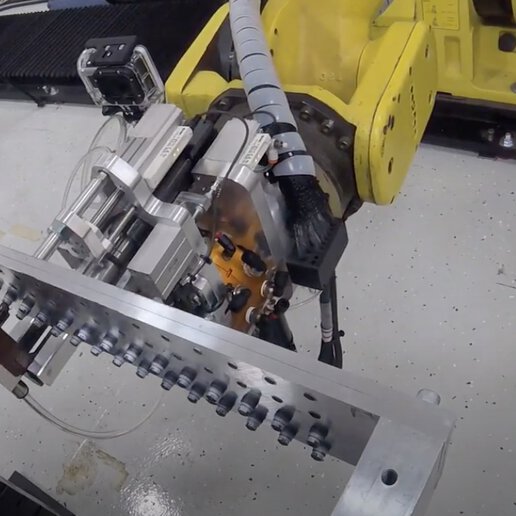

PAR’s automated cutting and trimming systems provide customized, high-tech solutions to maximize productivity, whether cutting composite parts, metallic components, or other materials. Our expertise with advanced waterjet cutting, spindle trimming, and ultrasonic cutting paired with our design expertise in system engineering, deliver a fully automated system that provides significant quality and productivity advantages.

Robotic & configurable fixtures

Proven techniques for tackling manufacturing challenges.

Configurable fixtures can eliminate dedicated tooling and the associated design, production, maintenance storage, and handling costs. From mapping as-built conditions and morphing tool paths to match to utilizing integrated process heads, PAR has developed various Adaptive manufacturing strategies that utilize patented techniques to enable the production of critical components and assemblies with exacting tolerances. Our solutions result in impactful ROI and gains in efficiency and productivity.

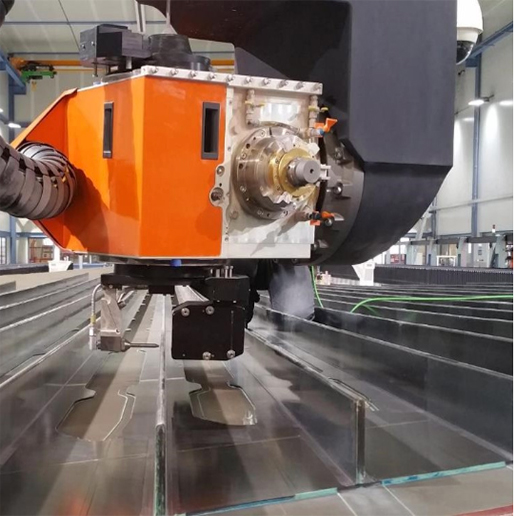

Friction Stir Welding

The superior welding solution.

Take advantage of the many benefits of the friction stir welding process with PAR’s machines and advanced control system. Our expertise and innovative methodology make deployment simple, even for large, complex applications.

PAR has highly-instrumented, high-fidelity solutions and a flexible control system tailored for process control and monitoring in a variety of motion systems. The combination makes PAR’s I-STIR™ technology the most advanced friction stir welding solution on the market.

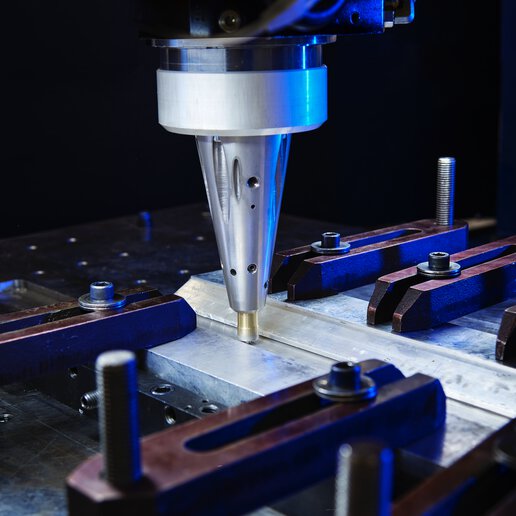

Drilling and Defastening

Precision and automation for critical requirements.

Precision drilling is a critical requirement for assembly operations. Whether drilling determinant assembly holes or precision fastener holes in composite skins or multiple material assemblies, PAR provides precision drilling expertise. Our defastening systems automatically locate and remove fasteners. This same automated defastening system can then produce fastener holes in the replacement skin that correspond with the existing substructure.

Service and Support

A global network of support and expertise.

Our global consulting team can work directly with you to resolve the most complex challenges with advanced manufacturing. In addition, our experience across processing, handling, assembly, and testing makes us experts in maintaining your equipment–whether we helped you design it or not. We can help with spare parts needs, equipment upgrades, install and training services, and much more to make your systems run right, from start to finish.

PAR Systems’ Advanced Manufacturing Technologies at Work:

The PAR Advantage

Let us work with you to create a solution for your most challenging manufacturing applications. From design, to implementation, production, and maintenance, our advanced manufacturing systems enable you to:

Save time and money

- Significantly improve cycle time, reduce costs, and improve productivity

- Eliminate the need for different tooling for each part or assembly and accommodates families of parts

- Eliminate costs of dedicated tools associated with: Design/Build, Qualification, Handling, Storage, and Maintenance

- Save time associated with introduction and removal of dedicated tools

- Eliminates skin damage from disengagement during fastener removal

Make processes more efficient

- With multi-part loading, different parts can be cut more efficiently by combining common processes

- Integrated process head allows multiple process tools to be integrated into a single end effector or machine

Create for a safer work environment

- Automated fastening eliminates operator fatigue and repetitive use injuries

- Eliminate risks to personnel from handling heavy and awkward tools

- Eliminate dust from cutting and trimming environments