Lubricity Testing

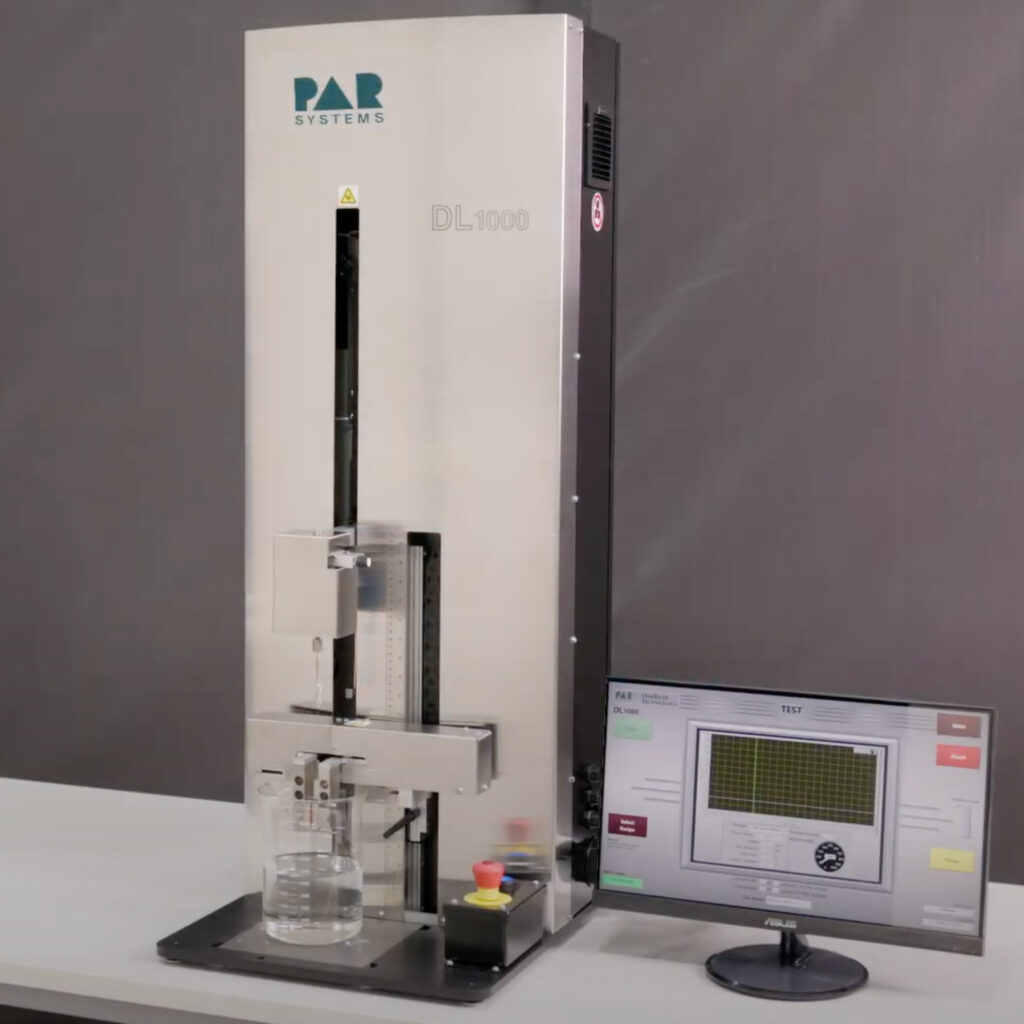

PAR Systems’ DL1000 Durability & Lubricity Test System accurately measures the durability and lubricity of medical coatings on catheters and guidewires.

Easy-to-Use and Flexible

The DL1000 is a lubricity testing system used for medical device durability testing after dip coating. This system features easy-to-use controls and flexible tooling to maximize productivity and to better suit the needs of your lab and production applications.

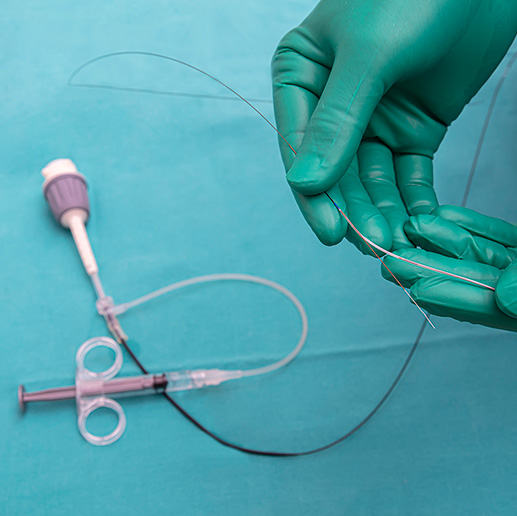

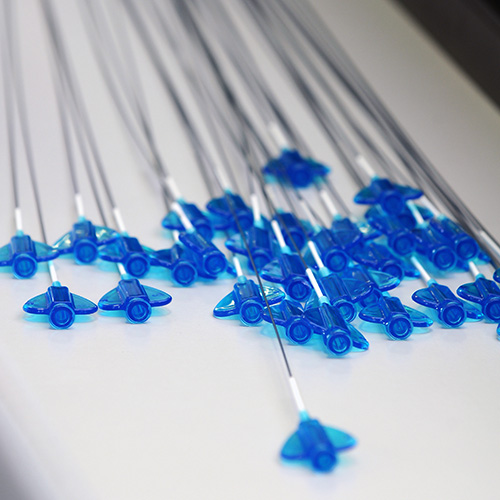

Designed for testing coated medical devices.

PAR’s durability and lubricity tester is designed to be flexible in order to reliably test catheters and guidewires in a variety of applications.

After testing, the resulting values are plotted in real-time. That raw data is both stored in compliance with CFR 21 Part 11 and used to generate a comprehensive, customizable test report to give you further insight into the performance of the coating.

Develop the perfect tests for each product. Rest assured knowing that your data is secure.

The DL1000 Features:

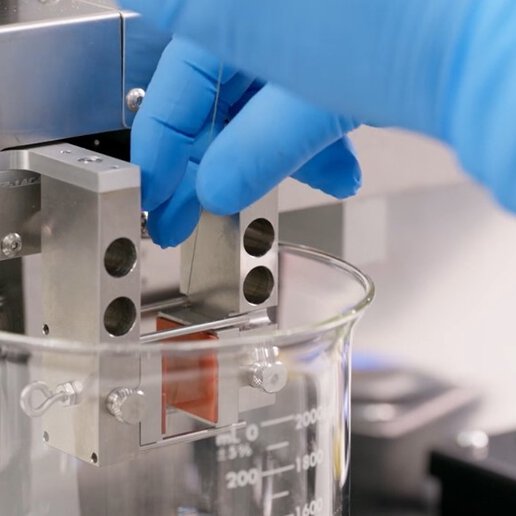

- Customizable and interchangeable gripper pad cassettes

- 6 interchangeable fixtures for optimal device holding

- Removable base plate that allows for an extended tank, heated baths, torturous path fixturing, and other customizations

Easy-to-use software and controls.

- Consistent testing via actively measured and controlled gripper forces

- Tool-less 5-point calibration of load cells in less than 10 minutes

- Highly configurable recipe setup with ‘teach’ functionality for position capture

- Data acquisition up to 125 Hz

- Secure data collection and storage per CFR 21 Part 11 and customizable summary reports

The PAR Advantage

PAR has over 20 years of experience in the design, installation, and maintenance of complex solutions for the life sciences industry. This extensive experience with these particularly challenging applications makes us the best choice to provide lubricity testing solutions for your unique needs.

Through our worldwide service organization, we also offer dedicated support from a team of local field service engineers, and our global consulting team can resolve the most complex engineering challenges.

Our expertise shows in each element we craft.

"PAR is a great company all around. From proposal to design to delivery PAR does a great job."

Jeff L.

Principal Technician, Emerson

Certified in all the right places.