High Integrity and Specialized Cranes

Where off-the-shelf cranes lack certain capabilities, PAR Systems uses our experience with a wide range of custom solutions to manufacture cranes that meet the needs of the most challenging applications.

Our crane systems are in-use on some of the largest and most critical material handling applications in the world. We can design and build a first-of-a-kind crane when the standard cranes don’t meet your requirements.

PAR has engineered hundreds of innovative solutions for challenging environments. Our systems hoist critical payloads like space launch vehicles or aircraft manufacturing lines, work in construction sites with critical and unique requirements, such as underwater applications, environments with explosive particulate and gasses, elevated temperature situations, or conventional munitions demilitarization. Our expert team has the technology and experience to get the job done safely.

When your application requires:

- A very long lift

- High capacity

- High speed

- Extra safety

- Reach into corners of a structure

- Any feature that is not available from an off the shelf solution

PAR’s Specialty Cranes at Work

Our Specialized Crane Solutions and Technologies

Anti-Sway Crane Control

PAR Systems’ anti-sway technology, EXPERTOPERATOR™, is a hardware module that converts pendent commands into expert commands issued to motor drives. This enables all crane operators to perform like experts, eliminating hook sway and increasing efficiency and safety.

Installation of this technology is much faster than other anti-sway solutions, as it doesn’t require sensors. This also allows it to perform at any height, making it easy to install and use, no matter how challenging the application.

Crane Updates

Updating your crane’s DC drives to modern controls has many benefits. With expert help from PAR, a crane update can improve overall performance, lower necessary crane maintenance and operational costs, and conserve energy and reduce power consumption.

Our method of modernizing your crane also requires significantly less engineering and installation costs, gives you the option to keep your existing control system components, and will fit within the framework and enclosure of your existing system.

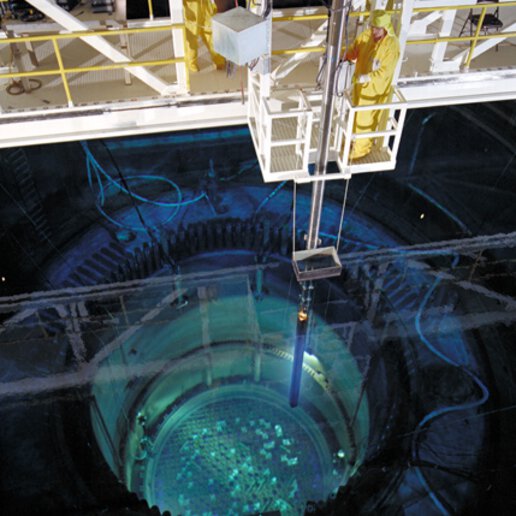

Nuclear Cranes and Equipment

With our deep expertise in complex applications and hazardous environments, we are industry leaders in designing and manufacturing specialized nuclear material handling equipment, including nuclear polar cranes.

We customize polar cranes to the needs of each customer. Here are some highlighted features within nuclear cranes we’ve created:

- Single failure proof hoist assembly

- Power rotational hooks

- Fail-safe operator controls

- Control upgrades

Our expertise shows in each element we craft.

The PAR Advantage

Innovation, Dependability, and Partnership

PAR has been in business for over 60 years. We design, manufacture, test, install, and support all of our machines and equipment for their entire usable life. This long history in innovative technology has helped us earn the trust of customers who return for second or third time replacement.

Our unique specialized crane systems and technology make it easier than ever to perform the most critical crane applications. Through our worldwide service organization, we offer dedicated support from a team of local field service engineers, and our global consulting team can resolve the most complex engineering challenges.