Medical Device Manufacturing

PAR Systems designs and builds manufacturing automation solutions for the medical device industry.

Engineering Specialists with Decades of Expertise

Medical device manufacturing requires specialty knowledge and the systems designed for quality, precision, and safety. Our life science experts have been designing and building medical device automation for over twenty years in multiple equipment areas including micro precision handling, medical device assembly, laser integration, dip coating, and more.

Optimize your operations with custom systems designed for:

- High throughput

- Unparalleled accuracy and precision

- Quality control

- Process efficiency

Medical Device Applications

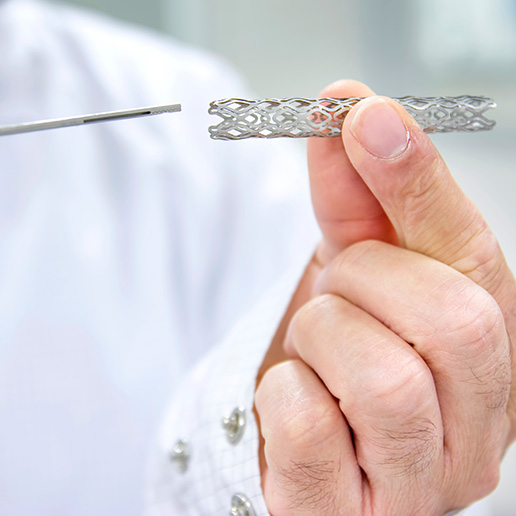

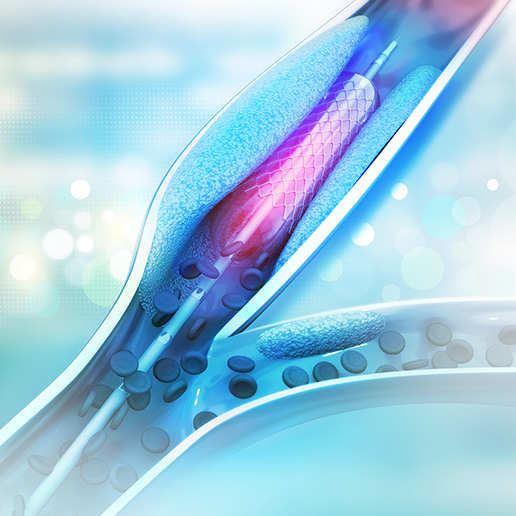

Implantables

Manufacturing implantable medical devices requires ensuring the production of high-quality products, a task that often involves complex manufacturing processes. With application expertise, we can help you implement new systems that are tailored for reliability, safety, durability, and operational efficiency. One of our specialties in automation is complex small part precision handling and assembly.

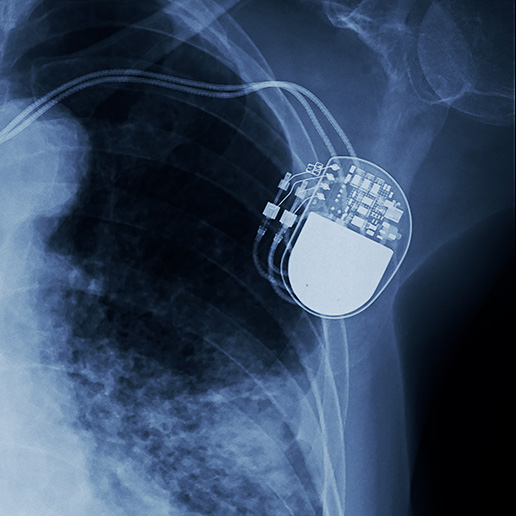

Wearables

The wearable medical device market is a high-growth area, and production needs to adjust to meet the rapidly growing demand. High quality automation solutions can help you improve throughput and efficiency while keeping quality control high. PAR can help you create automation systems in many areas of wearables production. One of our proven areas of expertise is battery manufacturing. We have years of experience building customized automation solutions for each step of battery production.

Disposables

Every therapy area has a significant need for reasonable cost, high-quality medical disposables. Strict quality control is critical and throughput needs are high. PAR offers customized smart automation systems, meticulously designed to align with your specific requirements, enabling you to improve your overall equipment effectiveness (OEE) KPI.

Learn about PAR’s dip coating and lubricity testing systems.

Common Therapy Areas

Additional Industry-Leading Capabilities

The PAR Advantage

PAR has over 20 years of experience in the design, installation, and maintenance of complex solutions for the life sciences industry. Our focused efforts ensure the best possible performance in these three key areas:

- Singulation of spheres that have diameters less than 300 microns and placement within 5 microns positional accuracy

- Singulation and processing of wires smaller than a 0.001″ OD (~25 microns)

- Flex-feeding and laser welding of metal brackets with 96 unique SKUs

- Drilling 75-micron OD holes into platinum domes via femto laser and seven-axis scanhead, with systems running at 99% yield

- Automated cable set assembly, including identification of each conductor by color, stripping, tinning and brazing to the appropriate bulkhead location

- Designed and build a robotic adhesive dispense system in five weeks (from purchase order to shipment) for COVID-related application

- Commissioned a custom bore inspection system in six weeks (including CE compliance testing) in response to a product recall for a medical device company

Our expertise shows in each element we craft.

"High quality systems and excellent systems integration. Better than others I have worked with."

Mfg. Engineer

Leading Medical Device company

Certifications and associations where it matters.