Laser Integration and Processing

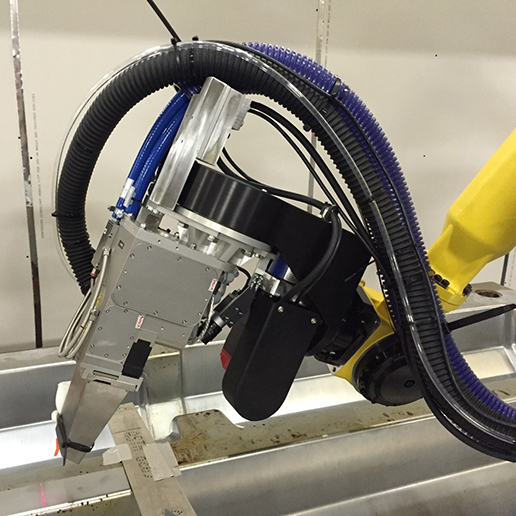

At PAR Systems, laser integration is a core competency in our process automation offering. Our laser automation capabilities include cleaning, cutting, drilling, scribing, welding, ablation, milling, inspection, and processing.

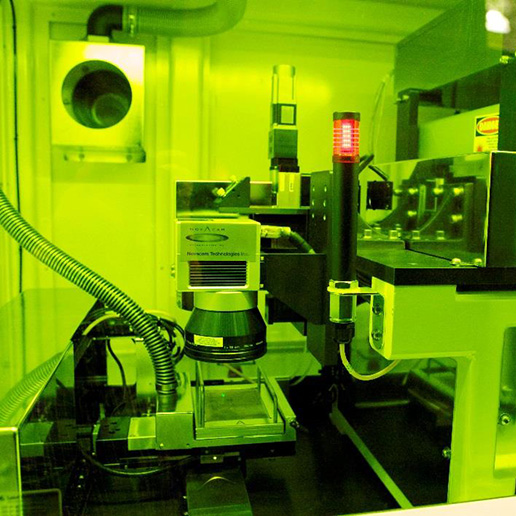

Our Laser Platforms

Easy-to-Use and Reliable

Our laser platforms are flexible, CDRH Class 1 laser platforms that are flexible and reliable.

With customizable product fixturing, these platforms were designed to be easily configurable to help design a larger laser processing system. The simple drag-and-drop programming interface provides a no-code development platform that allows users to quickly and confidently develop programs. Our platforms have the adaptability required for research and development applications and the reliability demanded in production settings.

Let Our Expertise and Experience Work for You

We work with all major laser manufacturers to facilitate early-stage process development.

PAR integrates laser processes using flexible platforms to meet a variety of your laser process needs. Our laser systems are easily configurable to accommodate specific applications and can be customized with product fixturing to adapt to unique manufacturing processes.

- Fiber

- Femto

- CO₂

- Excimer

- YAG

- TEA-CO₂

- UV

- YV04

Key Applications for Laser Integration

Laser Cleaning with CO(2) Lasers

Reduce costs & downtime.

The use of CO₂ lasers in laser paint removal is especially favorable due to the excellent absorption characteristics in the laser’s wavelength region. In addition, a laser based system has several advantages over alternative cleaning methods because molds do not have to be cooled down and can be cleaned in place. This results in substantial savings due to the decrease in down time.

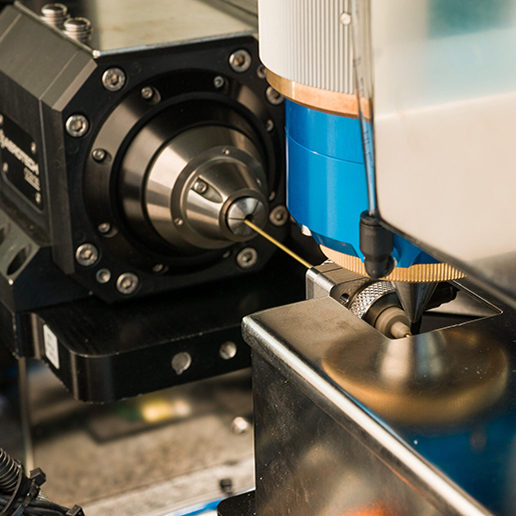

Wire Ablation

The complete package.

Our wire ablation systems are complete solutions and our package includes system layout and design (including mechanical and electrical design), controls design and programming, system assembly, delivery and testing, standard documentation package, warranty on parts and workmanship, and installation training.

Our ablation systems offer many critical and high-tech features including touchscreen HMI, HEPA filters, adjustable gear motors, servo sensors and motors, pneumatically powered die set, easy change out tooling, laser (type varies per application), custom optics, custom beam path, ablation vision technology and the latest software technologies.

More applications where PAR laser integration improves efficiency:

The PAR Advantage

Through our worldwide service organization, we also offer dedicated support from a team of local field service engineers, and our global consulting team can resolve the most complex engineering challenges.

Certified in all the right places.