SCADA Manufacturing Intelligence Solutions

Offering equipment-first solutions that provide reliable dashboards. We deliver data visualization that reflects reality and drives improvement.

We offer thoughtfully designed solutions that reflect reality and drive improvements. How?

- Equipment-first data models embedded into the control framework

- One cohesive engineering team builds the control architecture, equipment sequencing, and SCADA interface

- Parallel development of controls and visualization for faster time-to-insight

- Ignition® templates, scripts, and standardized transactions

- Dashboards designed around real operational behavior (OEE, downtime, rejects)

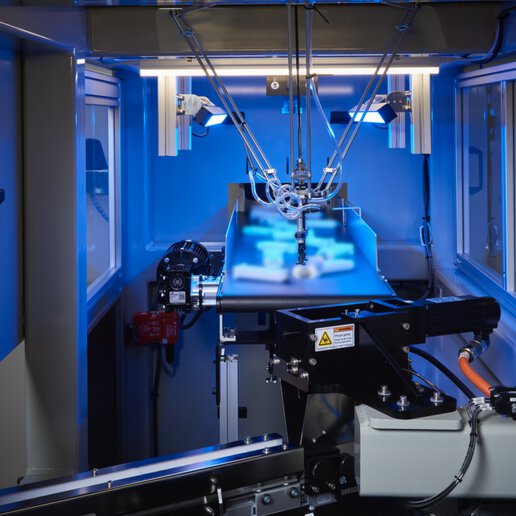

Redefining Data Visualization with an Equipment-First Approach

Modern production environments generate enormous volumes of data, but without structure and context, that data rarely becomes actionable. Too often, SCADA systems are bolted on and fail to reflect how the machine actually operates.

PAR’s SCADA and data visualization strategy helps us ensure every datapoint has a clear relationship to the process it represents.

- First, we understand how product moves through the automation system and how the machine reacts, recovers, and records information.

- Then, we embed the required logic, state tracking, and data models into the machine control framework.

Understanding Equipment Behavior for Better Data

During machine development, our engineers evaluate how data will be created, consumed, and interpreted throughout the system.

What We Model

- Faults, events, and recovery: Which faults matter and how the machine responds and returns to productive operation.

- Product and process data flow: How data moves with product through the system to preserve context.

- Disposition and fault codes: How parts are dispositioned and why, using clear reject and fault-code definitions.

What We Calculate and Trend

- Quality and performance drivers: Which parameters influence quality, throughput, and stability.

- OEE done correctly: Accurate definitions for Availability, Performance, and Quality based on real machine behavior.

- Process trending and monitoring: Which process variables are valuable for monitoring, trending, and early warning signals.

Faster Time to Actionable Data

Many manufacturers rely on one partner to deliver automation equipment and another to develop the software and analytics needed to extract value from it. This separation often creates delays between machine delivery and actionable insight. PAR eliminates that delay by developing both in parallel.

Parallel Development

Rather than treating SCADA as an afterthought, we develop the equipment control code and data visualization framework concurrently to provide:

- Accurate, complete event definitions

- Consistent data models across equipment

- Transactions aligned to operational behavior

The results?

- Shorter time between equipment startup and actionable data

- Fewer retrofits and data cleanup projects

- Higher trust in the data by operators and engineers

Intelligence Platform Built on Ignition®

As a Gold-certified Ignition Integrator, we deliver high-performance SCADA solutions built on a proven, scalable platform. Our systems extend Ignition with a robust library of standardized templates, scripts, and data models that integrate seamlessly with our machine control framework.

The PAR Advantage

By combining our machine-first engineering approach with a robust SCADA framework, we deliver systems that provide operational impact and continuous improvement.

- Gain trustworthy data.

- Improve troubleshooting speed.

- Enable Continuous improvement and root-cause analysis.

- Monitor for preventative maintenance

- Scale easily as your production evolves.