Dip Coaters

Bring hydrophilic coating in-house with automated dip coating systems designed for catheters, guidewires, and long, tight-tolerance medical components- supporting single- or multi-layer processes with integrated UV curing.

Designed for Bringing Medical Device Dip Coating In-House

Our automated dip coating systems are purpose-built for medical device manufacturing, enabling consistent, repeatable coating processes within a compact footprint. A proprietary collapsible tube configuration supports long, tight-tolerance parts without bending- allowing full-length coating while reducing floor space requirements. Semi- or fully-automated operation improves quality and reduces operator variability, while dual-batch processing increases throughput. Intuitive controls support safe, efficient day-to-day production.

DC200 Dip Coating Machines

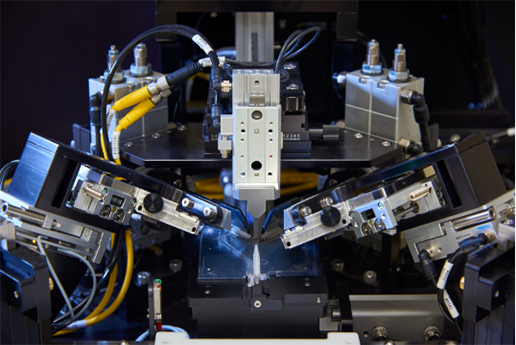

The DC200 Hydrophilic Coating Machine is an automated dip coating platform designed for low-particulate, low-friction lubricious coatings on catheters, guidewires, and other long medical devices. Supporting single- or multi-layer processes with multiple coating solutions, the DC200 enables repeatable, production-ready coating within a compact footprint.

A dual-batch architecture runs load/dip/dry operations in parallel with UV cure, maximizing throughput without sacrificing process control. PAR Systems’ proprietary collapsible tube configuration allows long, tight-tolerance parts to be coated without bending- reducing risk to the device while minimizing floor space requirements.

Simplified loading and unloading, combined with an automated and configurable process, help protect delicate products while supporting safe, efficient in-house production.

The DC200 offers:

-

Automated handling and precision motion control to improve coating consistency and reduce operator variability

-

Patented collapsible tube configuration that supports long, small-diameter medical devices without bending, while maintaining a compact system footprint

-

Dual-batch processing architecture to increase throughput by running dip and UV cure operations in parallel

-

Multi-solution containment to support single- or multi-layer hydrophilic coating processes

-

Intuitive controls and enclosed operation for safe, efficient day-to-day use in medical manufacturing environment

Key DC200 Product Features

- Up to 4 precision extract zones via servo driven motion

- Removable cassettes for easy loading and unloading

- Individual part rotation

- UV Filtered Windows

- Software Automatic and Maintenance Modes

- Intuitive software controls with visual cues for all key machine states

Customizable Features for Every Application

The DC200 is equipped with an array of customizable features and can be built and programmed to meet specific needs of one or more applications. Solution containment of multiple coating solutions gives flexibility to the coating processes. The DC200 is also equipped with recipe-driven software that enables customizable process control parameters, and the standard DC200 can be customized to accommodate longer part or coat lengths, larger part diameters, or larger batch sizes.

From Dip Coating to Lubricity Testing

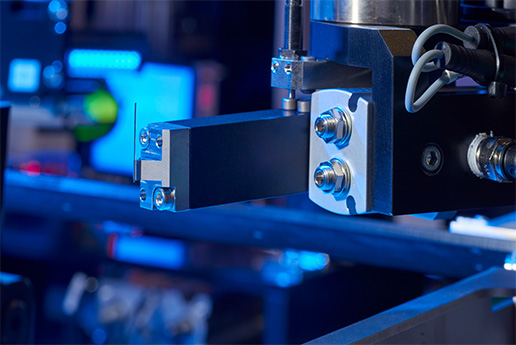

Interested in reliable, accurate lubricity testing in a flexible, easy-to-use system? Our durability and lubricity testers can help you ensure the quality of coatings on a variety of medical devices.

The PAR Advantage

PAR has over 20 years of experience in the design, installation, and maintenance of complex solutions for the life sciences industry. This extensive experience with these particularly challenging applications makes us the best choice to provide dip coating equipment for your unique needs.

Through our worldwide service organization, we also offer dedicated support from a team of local field service engineers, and our global consulting team can resolve the most complex engineering challenges.

Our expertise shows in each element we craft.

"PAR Systems has excellent customer service, solves issues quickly."

Leading Med Device Manufacturer

Certified in all the right places.