Medical Device Manufacturing

Empowering innovation in medical device manufacturing through tailored automation solutions that ensure safety, precision, and efficiency.

We Understand the Complexities of Medical Device Manufacturing

At PAR Systems, we know that behind every medical device is a human life — and that precision, cleanliness, and consistency aren’t just goals, they’re mandates. With over 20 years of experience designing custom automation for regulated life science environments, we bring the technical depth and process understanding needed to build equipment you can trust.

Our systems are built to solve the unique challenges of medical device manufacturing — including:

- Micro-scale precision handling for intricate components

- Seamless integration into cleanroom environments

- Compliance with ISO 13485 and related standards

- Complex assembly, laser integration, and dip coating processes

- Reliable quality control through inspection and testing automation

Optimize your manufacturing with custom automation designed for:

- High throughput without sacrificing precision

- Unmatched accuracy and repeatability at scale

- Tightly integrated quality control and traceability

- Process efficiency that supports scale-up and regulatory readiness

Delivering Results Across the Medical Device Industry

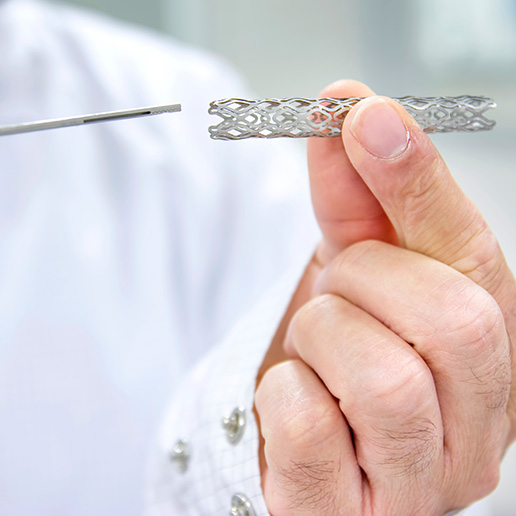

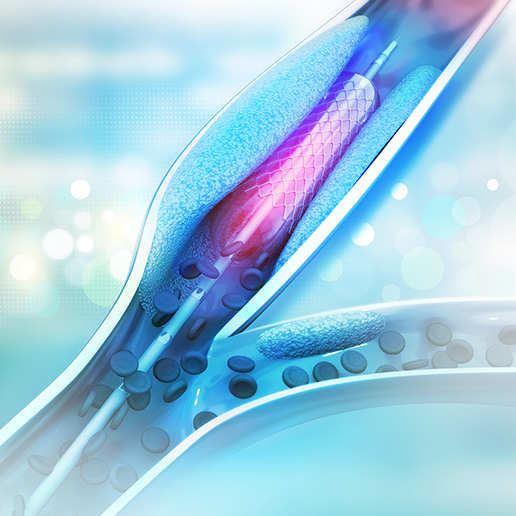

Implantable Devices

Implantable medical devices are among the most highly regulated and challenging products to manufacture due to their complexity, form factor, and exceptionally high performance and reliability requirements.

PAR Systems delivers custom automation systems that support the precision manufacturing needs of these devices while adhering to their strict regulatory requirements.

Diagnostics & Lab Automation

Diagnostics manufacturing and laboratory workflows demand tightly integrated systems that bring together devices, consumables, sample handling, and data—often at high throughput and under strict regulatory requirements.

PAR designs custom automation platforms that support diagnostic device manufacturing, lab automation, and disposable diagnostic consumables when standard equipment and fixed workflows fall short. Our solutions deliver repeatable performance, robust traceability, and seamless integration across laboratory and point-of-care diagnostic applications.

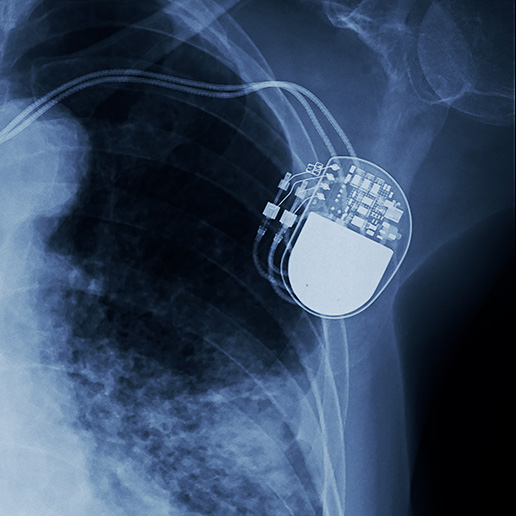

Wearable Devices

Wearable devices are changing how patients monitor and react to their health by providing continuous, real-world measurements outside of clinical settings.

PAR delivers scalable automation solutions for wearable devices, ranging from single-operator workstations to fully integrated high-volume production lines, enabling manufacturers to ramp from early production through full-scale commercialization.

Disposables

Disposables play an important role in modern healthcare by providing sterile, single-use components that reduce infection risk and support efficient clinical workflows.

PAR builds high-volume automation systems capable of supporting a wide range of disposable medical products for commercial or lab environments.

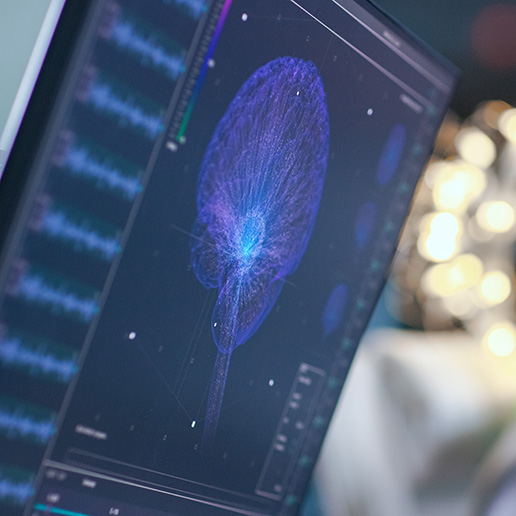

Manufacturing Intelligence

Modern medical device manufacturing depends on more than precision equipment- it requires intelligent software and trusted data to ensure quality, compliance, and scalability. From real-time production monitoring to validated data systems, manufacturers must maintain visibility and control across increasingly complex manufacturing environments.

PAR Systems delivers manufacturing intelligence solutions that connect automation, software, and data across medical device production. Our platforms support SCADA and MES integration, device and process-level software, and end-to-end data traceability- enabling manufacturers to make informed decisions, maintain regulatory confidence, and scale production with clarity.

Common Therapy Areas

Additional Industry-Leading Capabilities

The PAR Advantage

PAR has over 20 years of experience in the design, installation, and maintenance of complex solutions for the life sciences industry. Our focused efforts ensure the best possible performance in these three key areas:

- Singulation of spheres that have diameters less than 300 microns and placement within 5 microns positional accuracy

- Singulation and processing of wires smaller than a 0.001″ OD (~25 microns)

- Flex-feeding and laser welding of metal brackets with 96 unique SKUs

- Drilling 75-micron OD holes into platinum domes via femto laser and seven-axis scanhead, with systems running at 99% yield

- Automated cable set assembly, including identification of each conductor by color, stripping, tinning and brazing to the appropriate bulkhead location

- Designed and build a robotic adhesive dispense system in five weeks (from purchase order to shipment) for COVID-related application

- Commissioned a custom bore inspection system in six weeks (including CE compliance testing) in response to a product recall for a medical device company

Our expertise shows in each element we craft.

"High quality systems and excellent systems integration. Better than others I have worked with."

Mfg. Engineer

Leading Medical Device company

Certifications and associations where it matters.