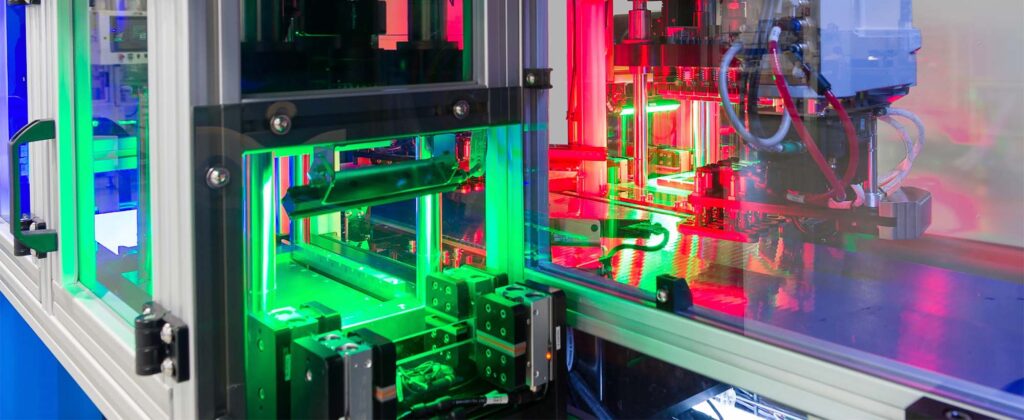

Discover how PAR Systems' custom automated aliquoting solution enhances precision, traceability, and efficiency in the life sciences industry, addressing challenges like contamination control, workforce optimization, and scalability.

PAR Systems, a leading innovator in precision robotics and automation solutions, received approval of its latest patent for an advanced manufacturing process technology that promises to revolutionize the manufacturing landscape.

PAR Systems built four FANUC robotic dispensing systems in five weeks, enabling a PPE manufacturer to produce 20,000 respirators weekly, aiding COVID-19 efforts.

PAR Systems partners with Winnebago Industries to install pedestal routers in Forest City, improving motorhome manufacturing efficiency with FANUC robots.

PAR Systems collaborated with Best Buy to create the Chloe robot, which retrieves items for customers using touch screens at their New York City store.

PAR Systems earned AS9100 Rev C certification, demonstrating its commitment to quality, safety, and reliability in meeting the aerospace industry's rigorous demands.

PAR Systems leads automation growth with innovative solutions for industries like aerospace, including support for the 787 Dreamliner and F-35 aircraft production.

- Previous

- 1

- Next