Spindle Milling & Trimming

High-speed, high-precision spindle milling and trimming systems built for large-part production and long-term performance in marine, aerospace, and composite applications.

Performance and Precision in Perfect Balance

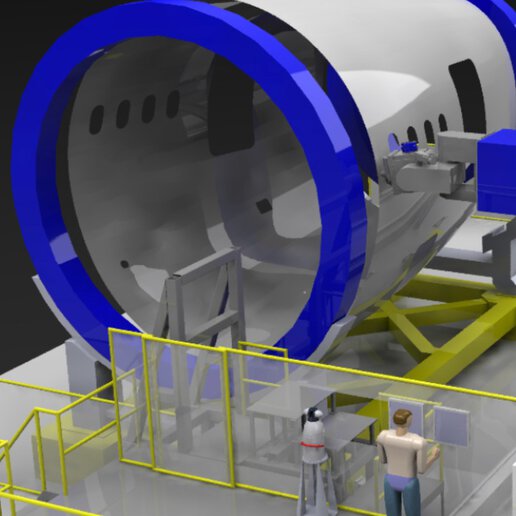

When precision and performance matter, conventional spindle trimming can be the ideal solution. From full fuselage barrels to composite panels, foam boat molds to fiberglass yacht edges—PAR delivers high-speed, high-accuracy systems designed to meet your exacting requirements.

Powerful Integrated Capabilities

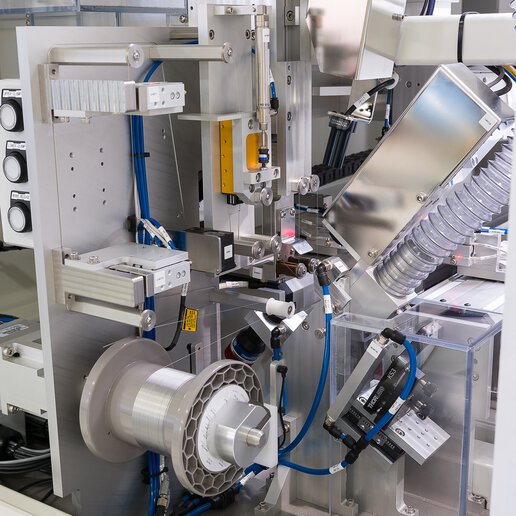

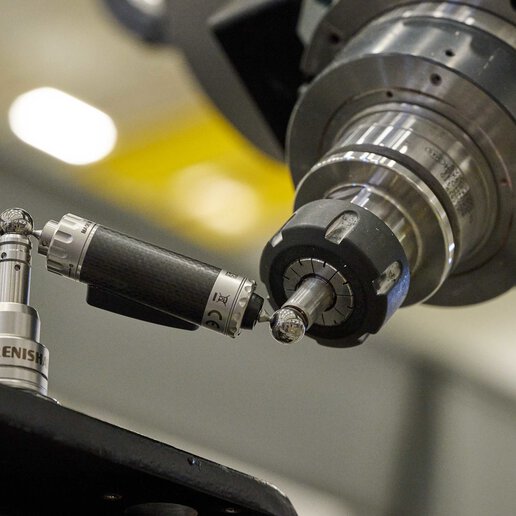

PAR spindle milling and trimming machines are engineered for precision, efficiency, and clean operation. Each system is equipped with advanced capabilities including RFID-enabled automatic tool changers, probe systems for part location and machine calibration, integrated vacuum dust collection for a cleaner workspace, and built-in inspection functionality. These features work together to deliver accurate, high-quality cuts while improving safety and reducing manual intervention. Whether you’re cutting composites, metals, or foams, our systems are designed to meet the rigorous demands of modern manufacturing.

Optimal High-Speed Cutting Solution

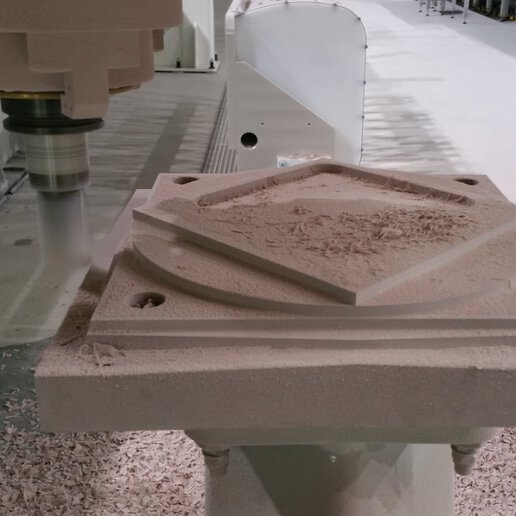

Spindle milling and trimming systems are ideal for high-speed, precision cutting—especially in challenging or constrained environments. These machines offer excellent depth control, making them well-suited for applications where only partial material removal is needed or when access to the back of the part is limited or not possible. Their versatility and accuracy make them a trusted choice for complex geometries and high-performance manufacturing needs.

Customizable and Configurable. Built for Your Needs.

PAR Systems spindle milling and trimming solutions are fully integrable into your production line and easily customized to meet your specific manufacturing requirements. Each system can be configured with either robotic fixturing for flexible, adaptive manufacturing or rigid dedicated tooling for maximum precision—depending on your application and environment. Designed for versatility, our systems handle a wide range of materials including composites, preforms, aluminum, titanium, glass, and ceramics with speed and accuracy.