Discover how PAR Systems' custom automated aliquoting solution enhances precision, traceability, and efficiency in the life sciences industry, addressing challenges like contamination control, workforce optimization, and scalability.

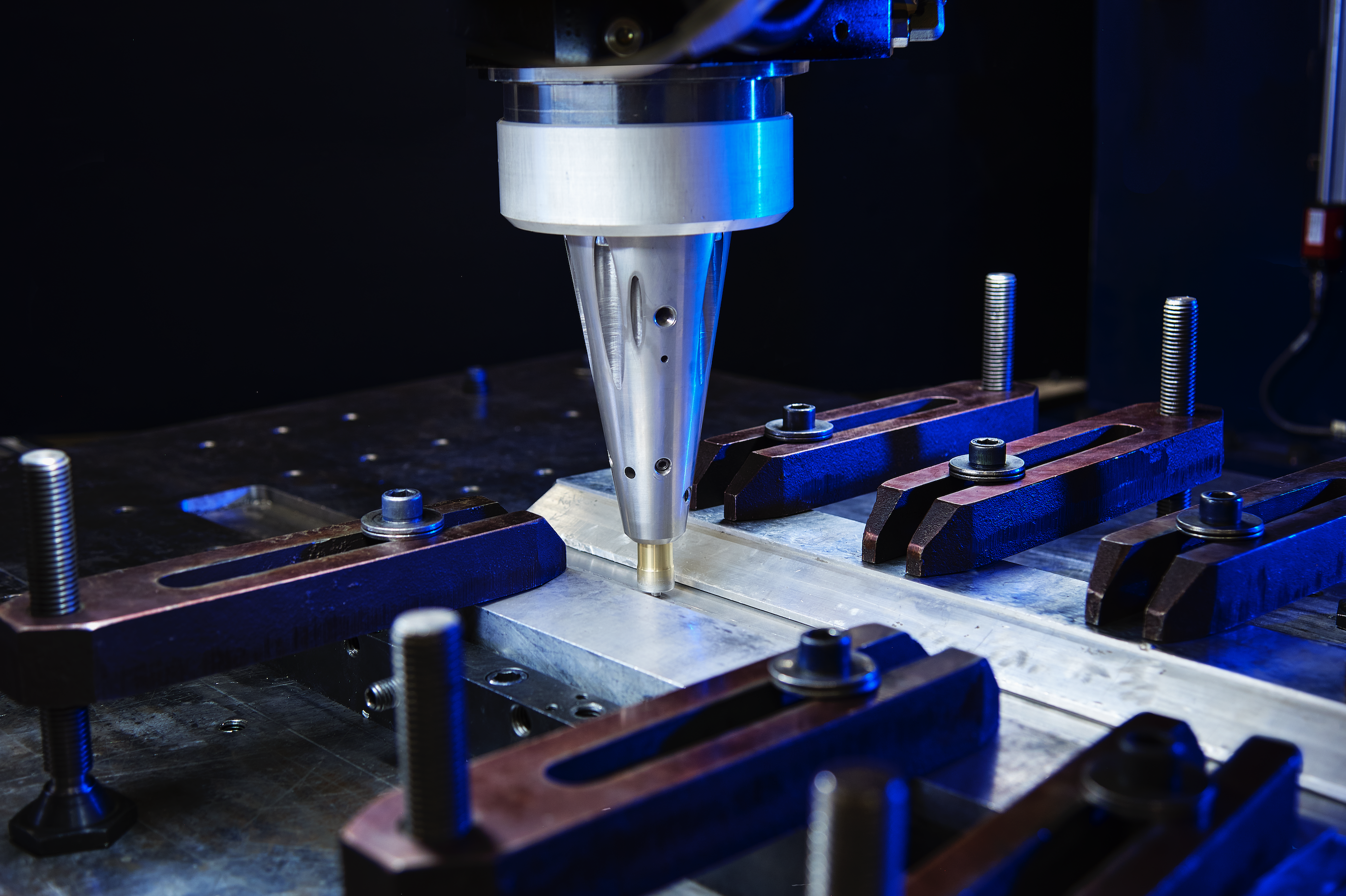

Friction stir welding is a solid state welding process that uses heat from friction to weld high-strength metals such as aluminum alloys.

PAR Systems, a leading innovator in precision robotics and automation solutions, received approval of its latest patent for an advanced manufacturing process technology that promises to revolutionize the manufacturing landscape.

Dr. Khalid Sorensen from PaR Systems will discuss advanced crane motion control at the Overhead Crane and Hoist Innovation Conference, highlighting anti-sway and safety benefits.

PAR Systems' I-STIR friction stir welding technology improves weld quality, speed, and safety, offering higher joint strength and reduced distortions for various industries.

PAR Systems was featured on KMSP-TV FOX 9 for its contribution to the Chernobyl New Safe Confinement clean-up effort, showcasing its critical role.

PAR Systems collaborated with Best Buy to create the Chloe robot, which retrieves items for customers using touch screens at their New York City store.

PAR Systems launched the I-RoboSTIR robotic welding system, utilizing Friction Stir Welding for high-accuracy, eco-friendly welds on 3D parts at high speeds.

PAR Systems launched the first 1,000 Hz TEA pulsed CO2 laser for commercial use, offering advanced laser solutions for industries like aerospace, physics, and healthcare.