First 1,000 Hertz Transversely Excited Atmospheric Pressure Pulsed CO2 Laser

March 6, 2014

First Ever 1,000 Hertz transversely excited atmospheric pressure (TEA) pulsed CO2 laser built for commercial applications was launched in January ’14. The laser was designed in-house by South African Laser manufacturer PAR Systems’ Center of Excellence (COE) for sdilasers™, based in Pretoria.

PAR Systems is one of only a few manufacturers in the world offering fully industrialized pulsed carbon dioxide lasers. In contrast to the well-known continuous wave (cw) low pressure CO2 lasers, transversely excited (TE) CO2 lasers are operated at atmospheric and higher gas pressures, emit short bursts of energy with durations of about 100 nanoseconds and peak powers of tens of megawatt at relatively high repetition rates. TE CO2 lasers find application in a number of highly specialised industrial and scientific processes, including the aerospace industry, atmospheric physics, isotope separation and accelerator technology.

Previously TEA lasers offered at atmospheric pressure provided pulse energies of up to 5 Joule with pulse durations of 60 – 150 nanoseconds and a maximum repetition rate 600 Hz. These lasers can be made to emit energy on a large number of individual fixed laser lines spanning the wavelength range from 9 – 11 µm in the mid-infrared. Using the agile grating control system – also a proprietary component developed at PAR Systems – fully integrated into the laser control, single pulse wavelength selection is possible at repetition rates up to 100 Hz.

PAR’s scientists and engineers in co-operation with the Laser Research Institute (LRI) at the University of Stellenbosch, have developed enhancements such as the sidearm catalyst, solid state switch and corona pre-ionisation now standard on the new 1 kHz TEA laser.

A sidearm catalyst system to recombine the small amounts of CO and O2 created in the discharge and prolong the gas lifetime. In applications where extremely long gas lifetimes of more than 1 billion laser shots are needed this systems saves on operating costs and reduces or eliminates frequent gas load changes.

A solid-state (IGBT) switched laser excitation circuit with a PaR-patented circuit topology, which replaces the conventional thyratron-based high voltage switching units. The circuit has already demonstrated long-term reliable operation in excess of 5 billion laser shots and PaR now estimates that this solid-state switch will prove to have a life in excess of 10 billion laser pulses.

A novel corona pre-ionisation technique replacing conventionally employed spark pre-ionisation improves laser stability, extends gas lifetime and long-term reliability.

The result of this partnership between industry and research institutions holds promise for many additional new developments presently being considered.

The company has exported pulsed CO2 lasers into as many as ten countries world-wide for diverse applications in science and industry such as:

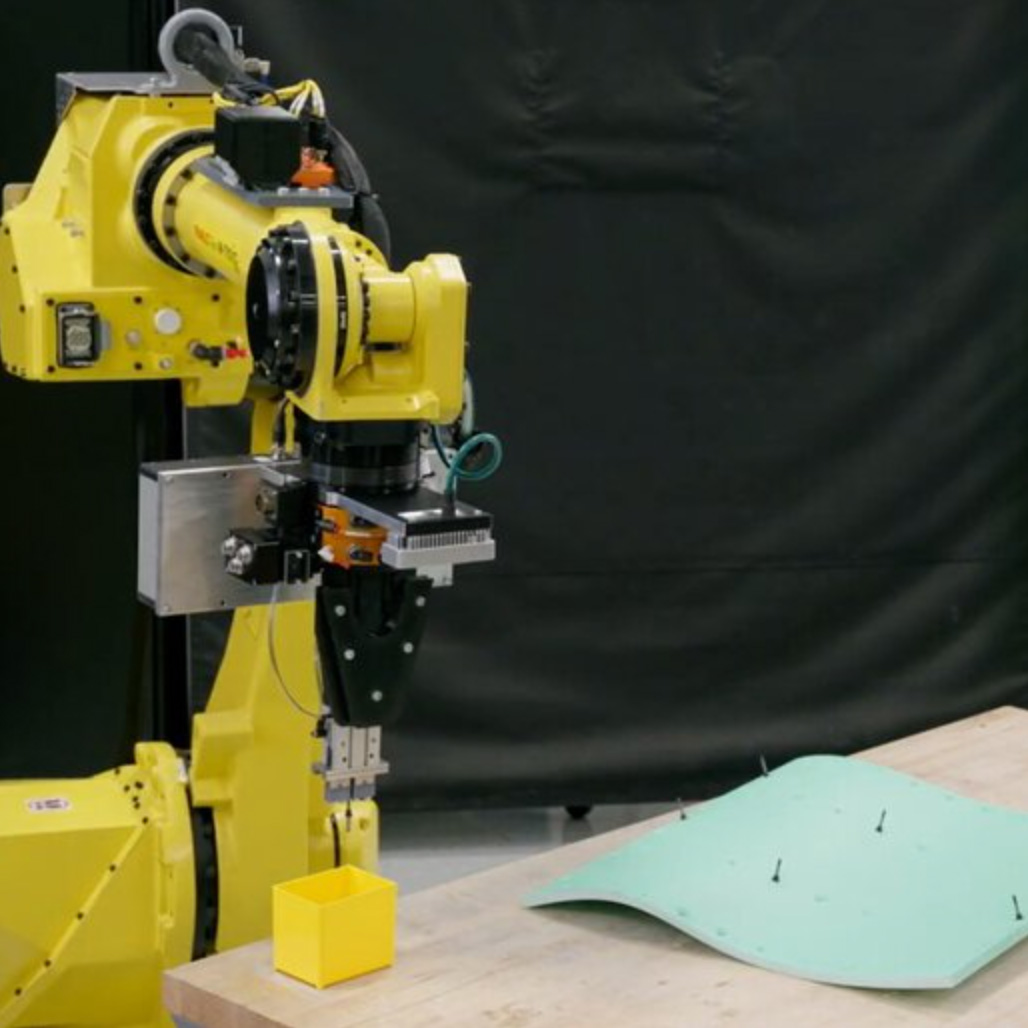

- Non-Destructive Testing (NDT) in the aerospace industry

- Light Detection and Ranging (LIDAR, DIAL) in atmospheric physics

- Extreme Ultraviolet (EUV) generation for photo lithography

- Paint stripping of composite and other surfaces in the industry

- Laser Isotope Separation (LIS)

- Wavelength shifting using Raman cells

- High energy physics

- Picosecond pulse amplification

- IR spectroscopy

- Cancer treatment research

Clients using PAR’s atmospheric and high-pressure CO2 laser systems include Brookhaven National Laboratory (BNL); Lockheed Martin aerospace, NASA, Kelly Space Technologies and the University of California Los Angeles (UCLA) in the USA; Airbus in France, the Chinese Space Agency; and several other big brand names around the world.

PAR Systems Center of Excellence for sdilasers™ was formerly known as Scientific Design & Integration (SDI) Lasers (Pty) Ltd. It is now a fully owned subsidiary of PAR Systems Inc. headquartered in Minnesota, USA. PAR Systems is a world leader in providing advanced engineered equipment, systems, and services for critical material handling and automation applications. PAR Systems creates custom-engineered manufacturing solutions for a broad range of industries including aerospace, marine, nuclear, heavy material handling, industrial manufacturing, and life sciences. This deep experience in providing custom engineered systems for complex applications allows PAR Systems Center of Excellence for sdilasers™ to provide fully integrated laser system solutions along with delivering state-of-the-art lasers.