PAR Systems brings proprietary friction stir welding to high-tech manufacturing

August 19, 2020

Mission-critical technology increases production speed with higher quality joints, less distortions, fewer emissions; Already providing competitive benefits to early adopters

MINNEAPOLIS, Aug. 19, 2020 — PAR Systems has been known by its long-term aerospace clients such as NASA, United Launch Alliance (ULA) and many others for its contributions to applications in perhaps the most demanding environment of all: space exploration.

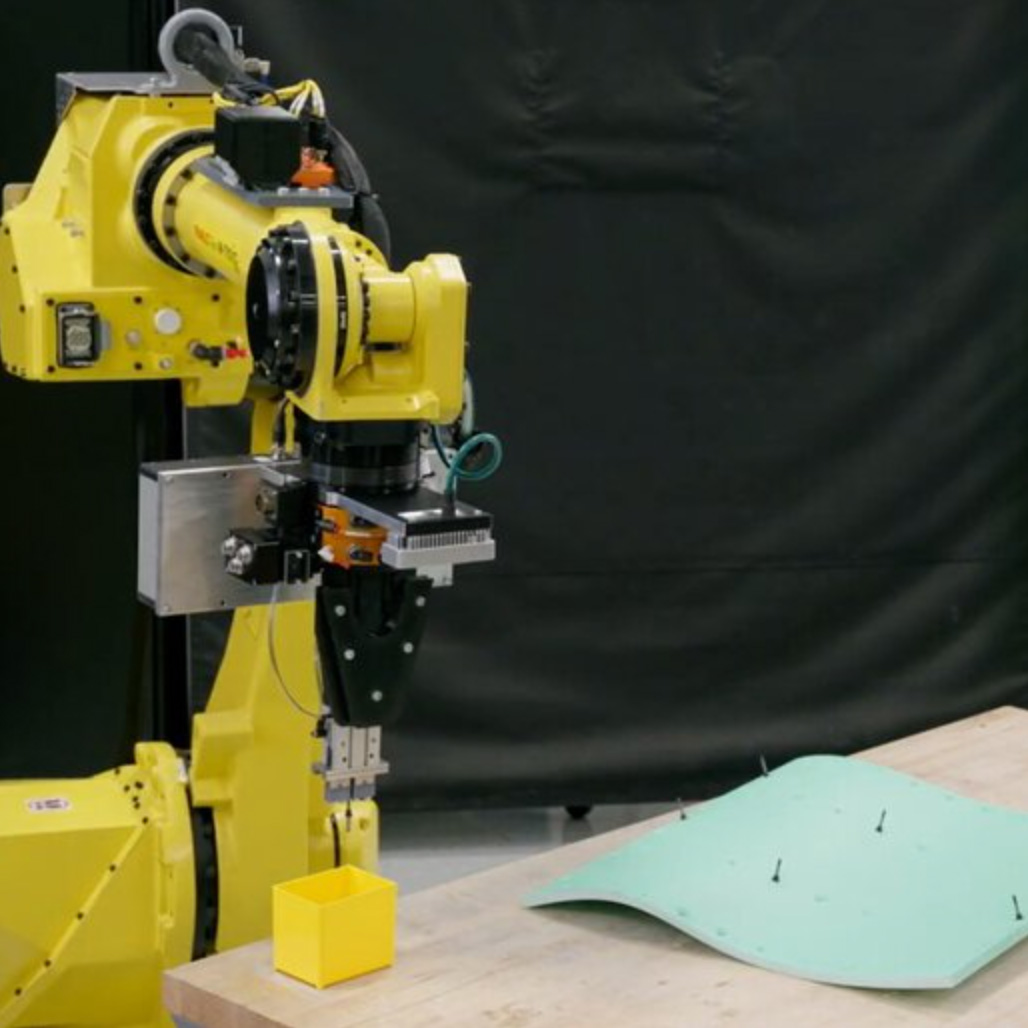

Now PAR is poised to bring its proprietary friction stir welding expertise down to earth to assist high-tech manufacturers to create lighter, stronger welds of higher quality in less time than traditional processes. PAR’s friction stir welding technology, known as I-STIR, can be used in the manufacturing processes of everything from semiconductors to computer monitors and electric vehicles to bridge decks and more.

“We see many possible applications of I-STIR for high-tech firms, and we are already working with some of them to create leading-edge solutions that provide a competitive advantage,” said Bryan Vogus, PAR’s vice president of sales for emerging markets.

PAR’s I-STIR friction stir welding solution produces higher quality welds than traditional fusion welding by using an accurate, repeatable and environmentally friendly process that stirs together two materials to create a single substance. Additionally, I-STIR can weld materials that were previously thought to be non-weldable, such as certain aluminum alloys. Steel, titanium, and other high-melting point materials are also weldable using friction stir welding.

These higher quality welds result in significant structural quality improvements. PAR’s I-STIR customers have seen joint strength improvements of up to 100 percent compared to traditional welding processes and static strength two times greater than comparable riveted joints. Large welded extrusion panels saw a tenfold reduction in distortion when using I-STIR friction stir weld technology.

PAR’s ultraclean friction stir welding process is greener than standard welding as it reduces scrap rates and provides a safer working environment than traditional welding, noted Terry Berglin, PAR’s director of business development. PAR’s I-STIR can be conducted at a lower temperature and creates fewer toxic emissions, enhancing the safety of production sites, he said.

To achieve ultimate flexibility, I-STIR has a patented self-reacting pin, which offers a high degree of precision in friction stir welding. Improving on the traditional shoulder and pin method of friction stir welding, the self-reacting pin has two shoulders to encompass the material. The second shoulder, located beneath the welding material, provides additional pressure to control the weld.

In addition to the self-reacting pin, I-STIR’s superior process control ensures the highest quality welds through careful monitoring and controls at every stage of the welding process. “One customer was able to replace over 7,000 rivets with 200 welds, employing a weld head control method that quickly adjusts based on position, speed or force feedback to maximize the quality of each weld,” Berglin said.

“We’ve been making stronger, lighter, higher quality products for clients in the aerospace and automotive industries for nearly 60 years, and we look forward to bringing these same benefits to our new high-tech manufacturing customers as well,” said Vogus.

More information about PAR’s I-STIR friction stir welding is available at https://www.par.com/capabilities/advanced-manufacturing/friction-stir-welding/.

About PAR Systems, LLC

PAR Systems, a portfolio company of the Pohlad family’s operating companies, is a world leader in providing advanced intelligent solutions for critical material handling, automation, and robotic applications that drive customer quality, safety, and productivity. Since 1961, PAR has created fully integrated systems, which are often first-of-a-kind manufacturing solutions, for a broad range of industries including aerospace, hazardous material/nuclear, life science and process automation, marine/defense, heavy material handling, and industrial. PAR Systems is headquartered in Shoreview, Minnesota, USA and has engineering and manufacturing centers of excellence around the globe. For more information on PAR Systems, please visit www.par.com.

###

Media Contact:

Kate Lilja Lohnes

Lilja Communications

952-893-7140