PAR Systems

Maximize Safety and Operating Efficiency with PAR Anti-Sway Crane Systems

PAR EXPERTOPERATOR™ anti-sway crane control system allows for the movement of payloads in a swing-free manner, allowing crane operators to reduce payload swing by 85-95%

PAR anti-sway crane control protects your operators and bottom line.

Investing in an anti-sway crane system enhances workplace safety and provides financial advantages by reducing downtime and maximizing productivity.

Increase Productivity & Cycle Time by up to 40%

EXPERTOPERATOR™ is an advanced motion control system. PAR’s motion control software uses unique algorithms that enables crane operators to more easily, quickly, and safely control the movements of payloads. EXPERTOPERATOR™ anti-sway crane control system has been proven to:

- Increase safety of personnel and equipment

- Improve cycle time by up to 40%

- Reduce operator training time

- Provide more accurate load placement

- Reduce crane maintenance and extend crane life

Read about how anti-sway crane technology has been used in the automotive manufacturing industry.

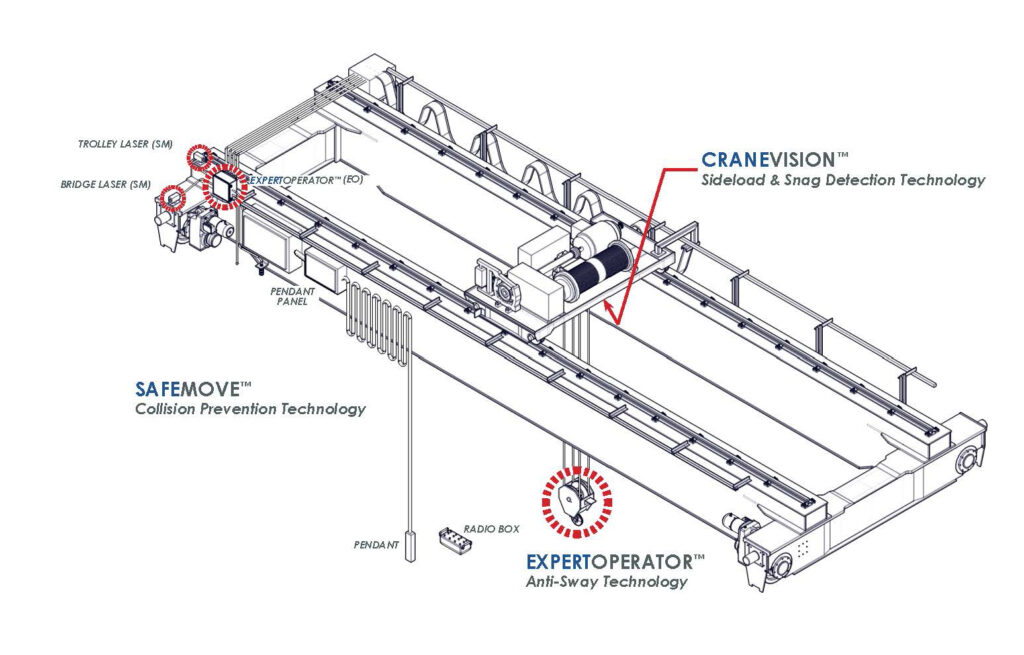

EXPERTOPERATOR™ Motion Control Modules

SAFEMOVE™, CRANEVISION™, AUTOMOVE™

See how it works.

The PAR anti-sway control system integrates into your existing crane platform with typical installation time of one day.

EXPERTOPERATOR™ is most effective for applications that require high throughput and precise manipulation of loads to meet production demands and prevent collisions with sensitive equipment and personnel.

Benefits of EXPERTOPERATOR™

- No Adjustments Needed: For height, sling length or load.

- Increased Safety and Collision Prevention: Load sway prevention reduces risk of equipment damage and personal injury.

- Minimized Downtime: This retrofit solution integrates into your existing hardware platform with typical installation time and of one day.

- Increased Productivity: Hundreds of operator studies demonstrate that cycle time improves by 10% to 40%.

- Maintenance Reduction: EXPERTOPERATOR is the only anti-sway crane technology that does not require sensors of any kind, even with complicated rigging configurations.

- No Operator Inputs Required: The sensorless system’s predictive algorithm seamlessly adjusts to any hook height, eliminating the need for manual height inputs.

- Compatibility: Seamlessly works with existing VFDs, radio and tethered pendants with continuous or multi-step functionality.

- Increased Accuracy: Accurate load placement is simple because operators focus on positioning rather than swing correction.

- Minimal Training: Novice operators perform as well as their experienced counterparts, reducing the need for extensive training.