For over 60 years, PAR Systems has been at the forefront of engineering, automating life-saving medical device assembly, safely handling hazardous materials like decommissioning Chernobyl, launching rockets into deep space, and enabling the development of next-generation nuclear power.

We collaborate with the world’s leading visionaries, offering everything from proof-of-concept studies to fully integrated automation systems, backed by ongoing service and support. Watch our corporate video, The Power of How, to learn more:

.

.

Join Us in Making History.

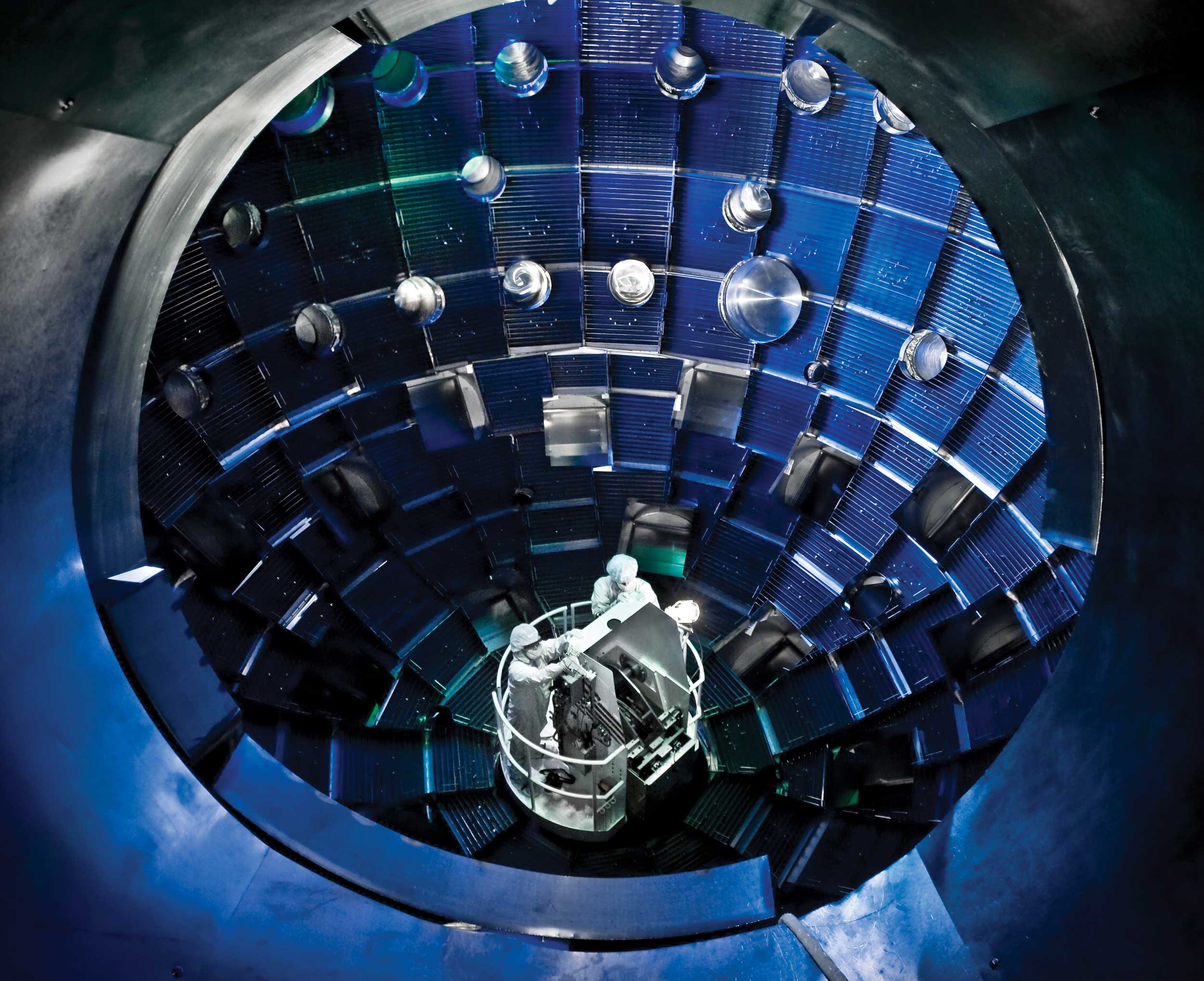

We bring our customer’s innovations to life. We partner with world-renowned innovators- delivering and supporting automation and handling solutions for even their most critical applications, Learn more about some of our groundbreaking projects like NASA’s Space Launch System, the Chernobyl clean-up effort, and cutting-edge innovations in nuclear fusion, medical device automation, and advanced manufacturing.

Our Core Industries.

Life Sciences

PAR Systems delivers cutting-edge automation solutions for the life science industry, specializing in precise small parts handling, laser integration, and assembly automation to achieve micro-scale precision enhance quality and machine efficiency.

Aerospace

We deliver world-leading aerospace manufacturing technologies—friction stir welding, automation systems, configurable fixtures, and precision cutting—to maximize productivity, enhance precision, and bring our customers’ innovations to life.

Nuclear

PAR Systems, a global leader for over 60 years, designs specialized equipment for hazardous nuclear environments, solving complex challenges in operating plants, research labs, decommissioning, and more with intelligent, tailored solutions.

Why Join Our Team?

- Innovate with Passion: Be part of a global team celebrated for its drive to invent and create groundbreaking solutions.

- Grow with Experts: Receive training and development from industry-leading professionals who are at the top of their fields.

- Foster New Ideas: Thrive in a culture that encourages innovation and embraces fresh perspectives.

- Live Our Values: Work in an environment rooted in strong, shared company values that guide everything we do.

- Support Your Well-being: Experience a workplace that genuinely cares for the health and well-being of its people.

- Enjoy Top-Tier Benefits: Benefit from cutting-edge perks designed for our full-time, regular employees.

Making a Difference Together.

At PAR Systems, we believe in making a positive impact not just through our innovative solutions but also by giving back to our community and supporting the environment. We’re committed to fostering a culture of responsibility, sustainability, and community engagement.