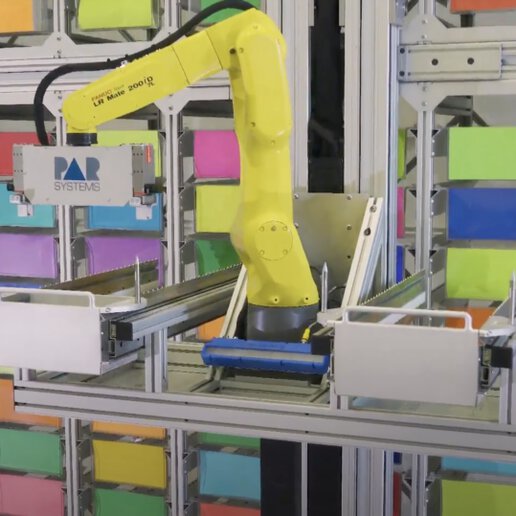

Smart, Scalable Material Handling Solutions

PAR Systems delivers intelligent material handling automation designed to meet the demands of high-throughput operations. From end-of-line packaging to palletizing and order fulfillment, our systems are engineered for speed, flexibility, and reliability across a wide range of product types and packaging formats.

Our Material Handling Systems

Order Fulfillment

Speed and accuracy are critical in order fulfillment. PAR’s fulfillment systems automate picking and packing to handle seasonal peaks, reduce errors, and meet today’s demand for rapid, reliable delivery. Our solutions are designed to scale with your operation, making it easy to adapt to changing product lines or volume growth.

Case Packing

For products that don’t fit the mold, PAR delivers innovative case packing systems that are custom to your application. Whether it’s delicate devices or oddly-shaped consumer goods, our robotic systems pack with precision, speed, and gentle handling. Each system is optimized for footprint and throughput, helping you maximize efficiency without compromising on product integrity.

Palletizing

We design custom palletizing systems that safely and efficiently stack products of all shapes and sizes—including fragile, irregular, or mixed-load items. Our palletizers are built to integrate with upstream packaging lines and downstream shipping systems, creating a smooth and intelligent flow of goods. With vision-guided robotics and adaptable end-of-arm tooling, our systems handle complex stacking patterns and variable loads with ease.

Integrating with all the right partners.

Trusted by the Brands You See Every Day

From motor oil bottles to snack packs, our systems are at work behind the scenes moving the products people use every day. Our automated handling solutions help some of the world’s most recognizable consumer brands deliver with confidence and consistency.

Why Choose PAR for Material Handling Automation?

- Proven experience including with CPG, food & beverage, and e-commerce clients

- Custom end-of-arm tooling for difficult-to-handle products

- Vision-guided robotics for precise orientation and placement

- Designed for rugged, high-speed production environments

- Scalable systems that grow with your operations

- Responsive service and support from design through deployment