PAR Systems

Medical Device Laser Wire Stripping

PAR Systems brings decades of experience and expertise to the field of laser ablation in the medical device manufacturing industry.

When insulation or layers of coating need to be removed from micro-scale wire for implantables or other medical device applications, PAR’s system design and proven components provide precision solutions.

There isn’t an automated laser wire-ablation challenge PAR can’t solve.

The team of skilled engineers and technicians at PAR Systems take pride in creating custom laser automation for medical device wire stripping applications that are tailored to meet any specific need. Whether it’s a standalone laser wire stripping system or an integrated automation solution, PAR has the expertise to deliver.

Incomparable. PAR is above and beyond the competition in every aspect.

Ken C.

Leading Medical Device Manufacturer

Why Work with PAR Systems

Precision and Accuracy

PAR laser ablation solutions provide best-in-class ability to precisely control the depth and area of material removal without damaging surrounding areas.

Efficiency and Speed

PAR laser ablation systems can operate continuously with minimal human intervention, significantly increasing the manufacturing throughput compared to manual processes.

Flexibility and Customization

PAR automated laser systems can be easily programmed to create complex geometries and fine details that would be difficult or impossible with other methods.

That's the PAR advantage.

PAR uses the most advanced laser ablation technology on the market and has proven experience designing complex, customizable wire stripping automation solutions built to suit any application—including upstream and downstream direct manufacturing execution software integrations.

Featured Medical Device Application Use Cases

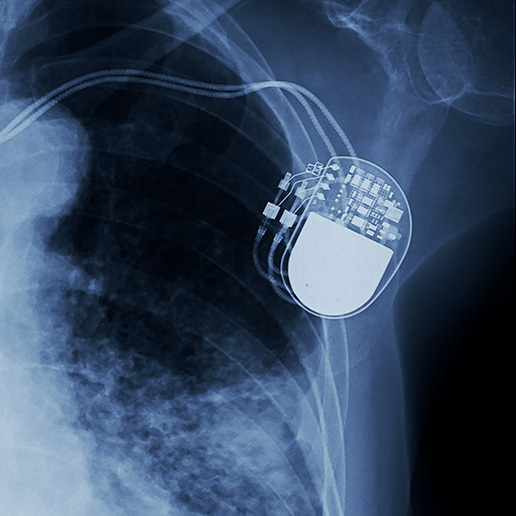

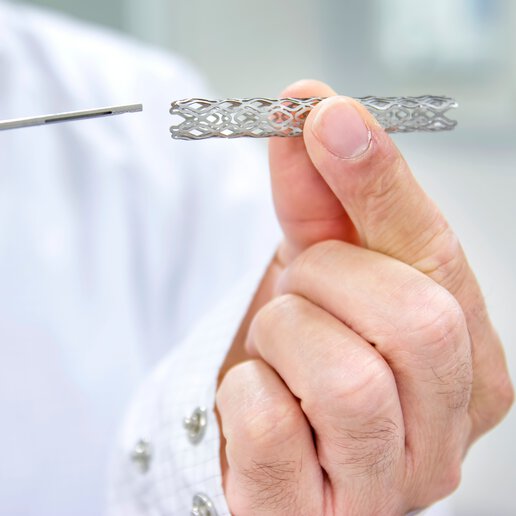

Laser wire stripping performance and accuracy are crucial in medical device manufacturing. You can trust

PAR Systems to build and support the most complex solutions across the entire range of medical devices,

from catheters, pacemakers, and neurostimulation diagnostic sensors to endoscopic tools and more.

- Micrometer-level accuracy for precise material removal

- Reliable, repeatable control with advanced control systems

- Easily follow complex curvatures

- Consistent results in complex applications

- Optimized workflows

- Improved data accuracy

- Enhanced production efficiency

- Tailored MES solutions