PAR Systems Awarded Main Cranes System Subcontract for Chernobyl NSC

August 3, 2010

Saint Paul/Minneapolis, MN (August 3, 2010) – PAR Systems, Inc. and its wholly owned subsidiary, Ederer, LLC, have been awarded a multi-million dollar, multi-year subcontract award for the Main Cranes System by NOVARKA, a French unincorporated joint venture made up of VINCI CONSTRUCTION GRANDS PROJETS S.A.S and BOUYGUES TRAVAUX PUBLICS S.A. NOVARKA was awarded the contract in 2007 to provide the New Safe Confinement for the Chernobyl Nuclear Power Plant located in North Central Ukraine. NOVARKA’s contract includes the design, construction, and commissioning of the New Safe Confinement (NSC), which is an arch structure that will be erected adjacent to the destroyed reactor and then slid into position. The NSC environmentally isolates the reactor building and will be used for future clean-up efforts for the destroyed Unit 4 of the Chernobyl Nuclear Power Plant (ChNPP). The environmental restoration work at Chernobyl is funded by 29 donor nations to the Chernobyl Shelter Fund, which is administered by the European Bank for Reconstruction and Development.

The Main Cranes System (MCS) is being designed, fabricated, and tested by PAR Systems with engineering being performed at Ederer in Seattle, WA, and PAR Systems’ Robotics headquarters in Shoreview, MN. Fabrication and assembly will be performed in Shoreview as well as PAR Systems’ wholly-owned subsidiary Jered LLC in Brunswick, GA. PAR is also responsible for the site supervision of the crane system erection.

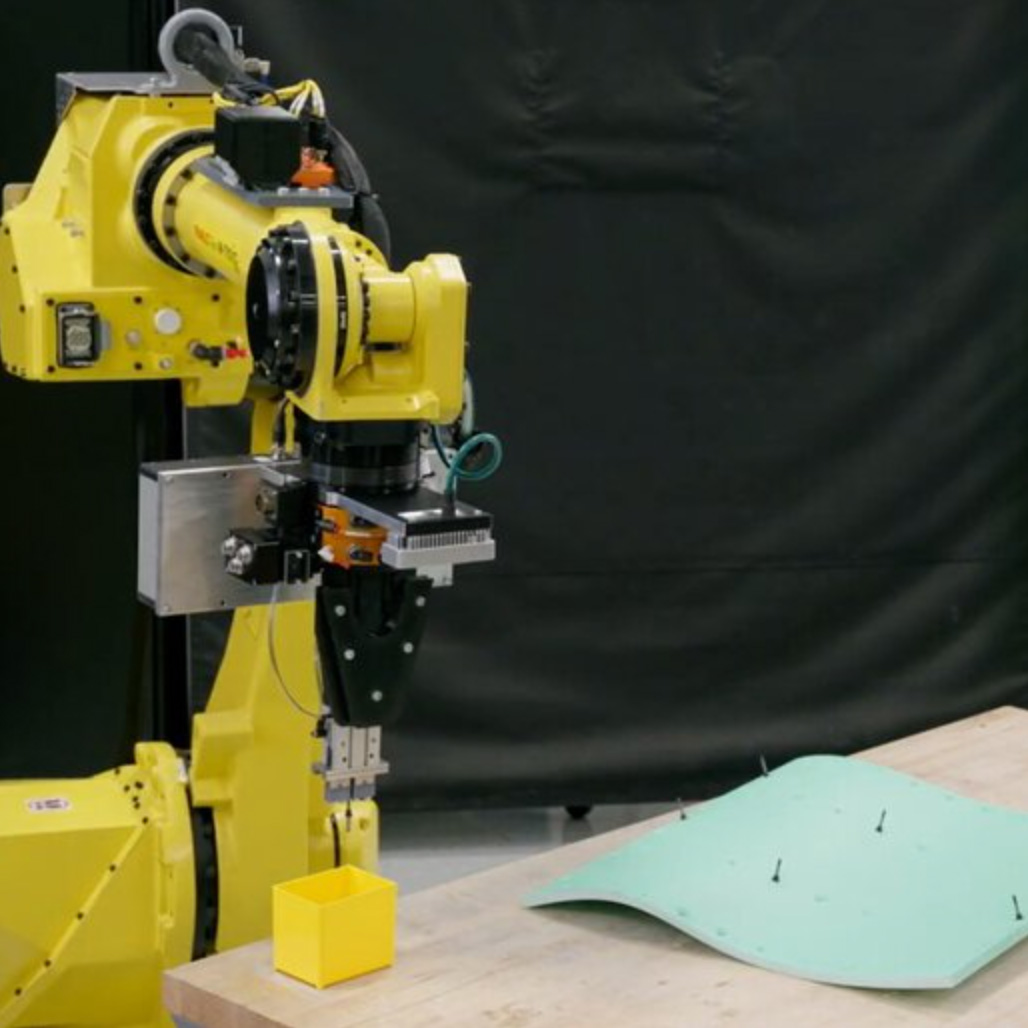

The MCS integrates overhead bridge cranes, trolleys, and a remote control and video monitoring system for operating the cranes system in a radioactive area. The MCS will be erected and operated inside the NSC building to allow site dismantle and cleanup in a controlled environment. The MCS includes two 50-tonne (55 US tons) trolley hoists that can work in tandem to handle loads up to 100 tonnes (110 US tons). A third trolley suspends a Mobile Tool Platform (MTP), which utilizes a RoboCrane® technology that was developed at the U.S. National Insitute of Standards and Technology and is licensed to PAR Systems.

About PAR Systems

PAR Systems is a leader in providing material handling and automation solutions to improve customer quality, safety and productivity. Since 1961, PAR has specialized in the design and supply of remote handling and automated systems for high radiation, high temperature, inert gas, and vacuum operations. Headquartered in Minnesota, PAR Systems serves a broad range of industries including aerospace, defense, food and beverage, hazardous material management, heavy material handling, industrial manufacturing, and life science. For more information on PAR Systems and its companies visit www.par.com.