PAR Systems Ships Largest Remote Robotic Nuclear Crane to Chernobyl

June 16, 2015

PAR Systems, Inc. Ships Largest Remote Robotic Nuclear Crane to Chernobyl for Reactor Cleanup

Remote Robotic Nuclear Crane Utilizes Advanced TensileTruss® Technology to Facilitate Destroyed Radioactive Reactor Cleanup Efforts

SHOREVIEW, MN, June 16, 2015 – PAR Systems, Inc. (https://www.par.com/), a world leader in specialty cranes, aerospace manufacturing, material handling, automation, and robotic solutions since 1961, announced today that its Shoreview based Cranes & Environmental Business has successfully completed factory testing and shipped the world’s most sophisticated remote robotic nuclear crane, the Main Cranes System (MCS). The MCS will be used exclusively for the cleanup efforts of the destroyed nuclear reactor at the Chernobyl Nuclear Power Plant in Ukraine. PAR Systems is providing their patented TensileTruss® technology which enables a rigid lightweight extendible Mobile Tool Platform (MTP), along with a full suite of specialized technologies, for robotic cleanup. This TensileTruss® technology was also provided by PAR to support the cleanup activities at the Fukushima nuclear site in Japan.

The Chernobyl nuclear power plant accident that occurred on April 26, 1986 destroyed Unit 4. After the accident, stabilization of the damaged reactor was necessary to minimize long term radiological impact on personnel and the environment. A temporary confinement building, the Object Shelter, was designed and constructed between May and November 1986 for containment, but is now considered unstable.

Construction of the New Safe Confinement Structure (NSC) located over the 30 year old Object Shelter will protect the environment from radioactive contamination during cleanup. The NSC will be fitted with PaR’s robotic cranes systems which will be used to deconstruct the Object Shelter, remove nuclear materials from the reactor core and finally for the removal of the reactor and other contaminated structures.

The MCS is enormous in size, measuring in at 96 meters long, which is longer than a Boeing 777, or if stood on end, taller than the Statue of Liberty. The MCS is made up of the four major components: two 96 meter (315 feet) bridges, a classic carriage hoist, a secure carriage hoist, and a Mobile Tool Platform (MTP) utilizing TensileTruss® technology. The MCS major components required extensive engineering and reliability analysis to ensure the MCS could operate in the harsh radioactive environment.

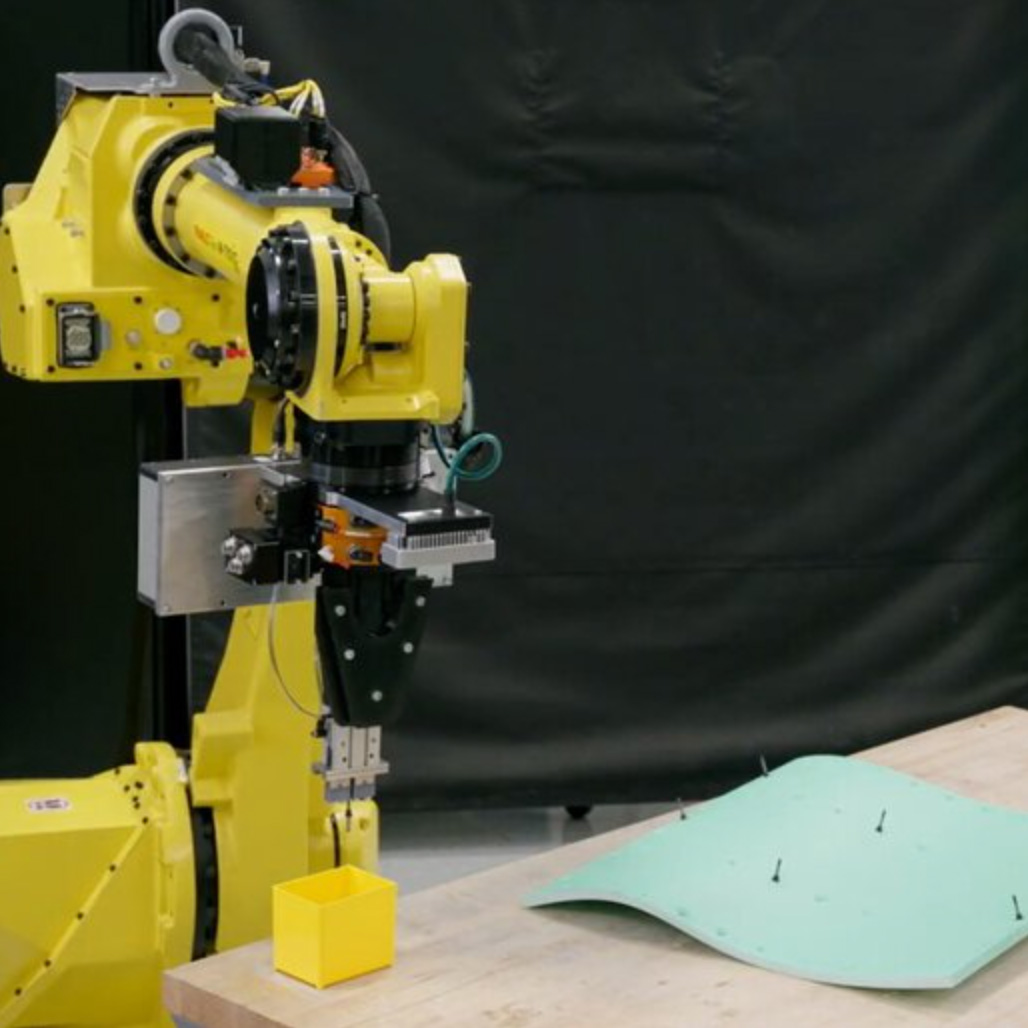

These components were designed and serve the purpose of safely cleaning up the decommissioned Reactor 4 in Chernobyl. The bridges were built to span the reactor building to ensure the full robotic cleanup. The underhung bridges were designed so that two fully loaded carriages may be on the same bridge at the same time, or driven into a maintenance or storage garage. The Classic Carriage hoist is used to transport cleanup tools and other materials throughout the cleanup site. The Classis Carriage hoist has a lifting capacity of 50 tonnes (55 tons) and a vertical lifting distance of 73 meters (240 feet). The Secure Carriage has a lifting capacity of 40 tonnes (44 tons) and is used to transport materials, or personnel. The Mobile Tool Platform (MTP) employs a custom designed TensileTruss® that serves as a stable tool delivery platform to support remotely operated high-capacity demolition tools as well as a vacuum and waste container to collect the debris. The MTP is comprised of two triangular platforms with independent wire ropes used to manipulate the lower platform. TensileTruss® technology is much more than the standard anti-sway technology used in the crane industry, due to its own inherit structural rigidity. Hoists on the MTP precisely control the tension of each wire rope, so that the lower platform can handle significant horizontal loads and torques generated by tool usage. The MTP can handle 1.5 tonnes (1.7 tons) of side load capacity at an extension of 44 meters (144 feet) without sway, which would be impossible to achieve with a standard hoist. The MTP allows for remote work to be completed that is remarkable due to the elevation and radioactive environment. The total vertical extension of the MTP is 70 meters (230 feet) enabling it to reach from just below the ceiling of the NSC all the way to the ground.

PAR Systems’ sophisticated crane system will be instrumental in safely cleaning up of one of the world’s worst nuclear accidents at the Chernobyl Reactor 4 site. The structural elements being dismantled will be large and heavy, so this massive and thoroughly engineered MCS is required for the safety of the citizens and the environment. PAR Systems is honored to have accomplished this great achievement of shipping the MCS that will soon be in use after several years of designing and testing this enormous system to operate for the life of the project.

About PAR Systems

PAR Systems, a portfolio company of MML Capital Partners (www.mmlcapital.com), is a world leader in providing advanced intelligent solutions for critical material handling, automation, and robotic applications that drive customer quality, safety, and productivity. Since 1961, PAR has created fully integrated systems, which are often first-of-a-kind manufacturing solutions, for a broad range of industries including aerospace, hazardous material/nuclear, life science and process automation, marine/defense, heavy material handling, and industrial. Headquartered in Minnesota, PAR Systems has global engineering and manufacturing centers of excellence. For more information on PAR Systems, visit www.par.com.

###