Automated Sample Aliquoting System

Introduction

In the life sciences industry, precision, traceability, and efficiency are paramount when processing patient samples. PAR Systems specializes in designing and delivering custom automation solutions tailored to these unique challenges. Our recent implementation of an automated aliquoting system showcases our expertise in addressing complex customer requirements while maintaining the highest standards of quality and reliability.

Critical Technologies Used:

Key Challenges

- Timely Processing: Samples must be processed within a strict time window after receipt to maintain viability.

- Contamination Control: Ensuring sterility and minimizing cross-contamination throughout the process.

- Traceability: Accurate tracking of samples and containers, ensuring proper barcode scanning and matching.

- Precision Handling: Avoiding sample loss or errors during aliquoting, capping, and storage processes.

- Scalability: Adapting the system to handle varying sample volumes and throughput requirements.

- Operator Retention: Addressing workforce challenges in repetitive and high-precision tasks.

Considerations when Choosing a Solution

When evaluating an automation solution for sample aliquoting, customers often face several critical considerations:

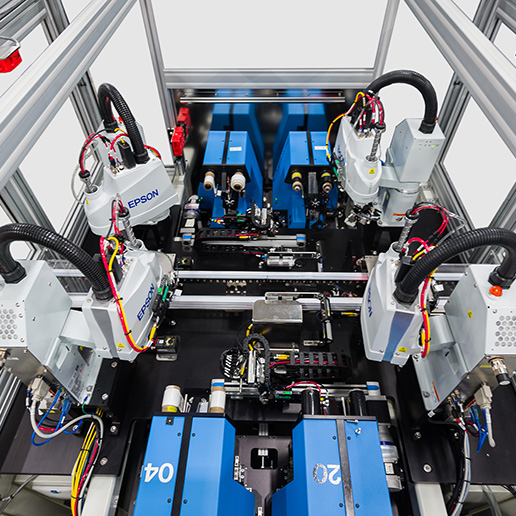

The PAR Solution

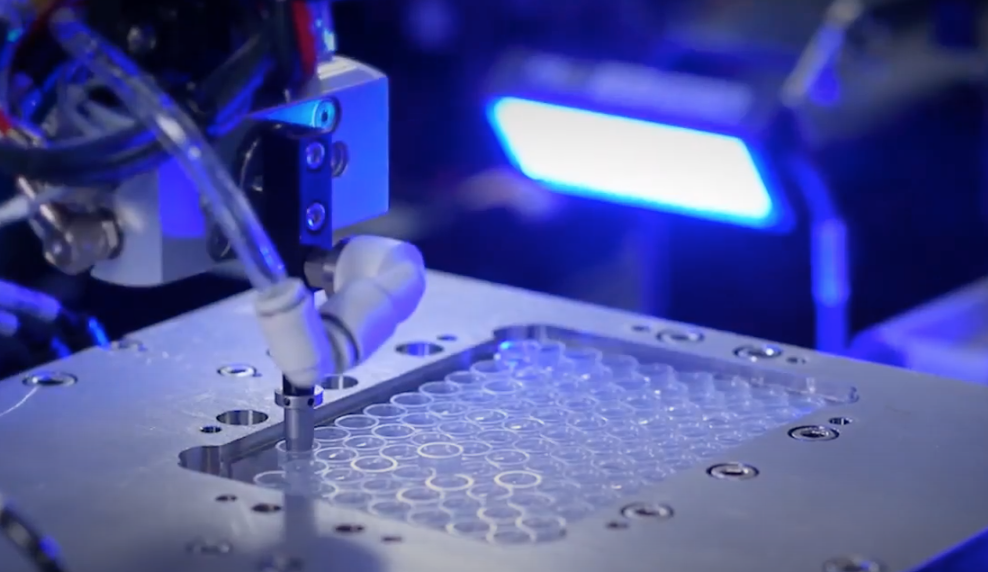

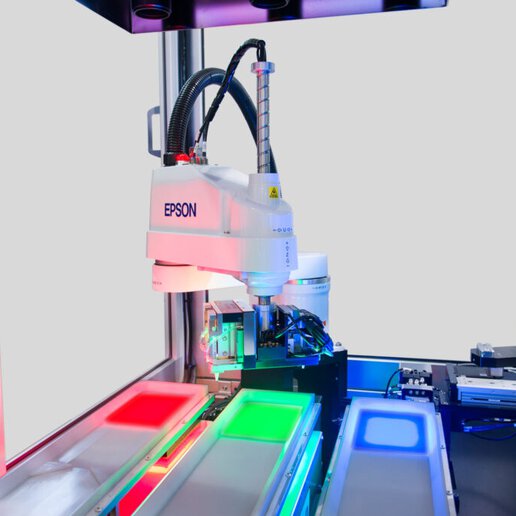

PAR Systems developed a custom automated aliquoting solution designed specifically for our customer’s requirements. The system delivers high precision, throughput, and contamination control, addressing the pain points of traditional manual methods.

Upstream Integration

- Samples arrive in containers at set intervals.

- Upstream processes include weight checks and other analyses to ensure samples are processable within the time window.

Automated Process Highlights

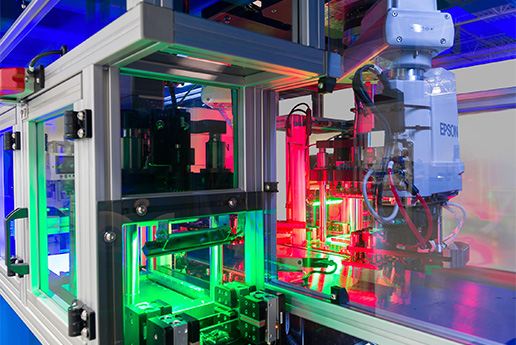

- Flexible Processing: The system automatically selects one of 12 identical cells for sample processing.

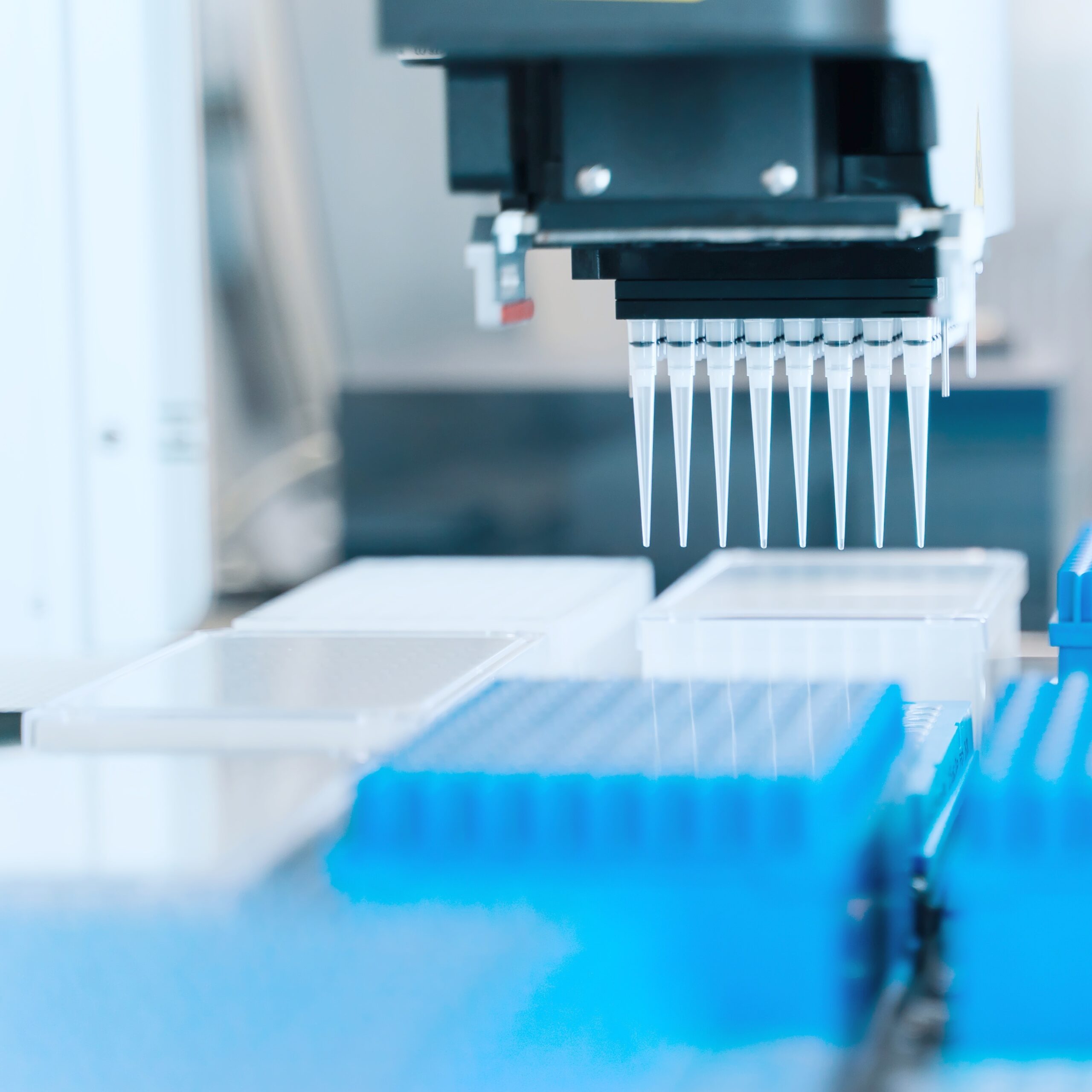

- Streamlined Workflow:

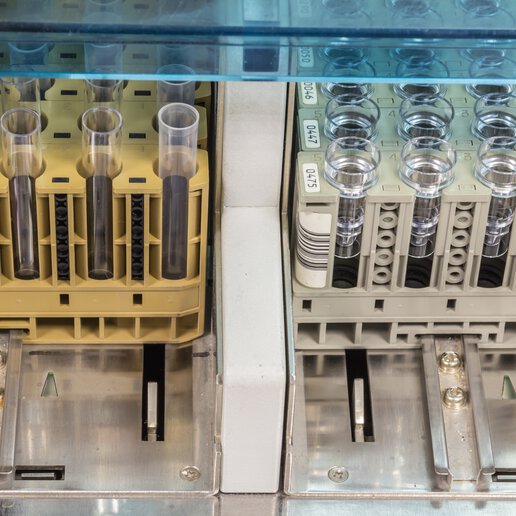

- Sample containers are opened, analyzed, and verified for processing.

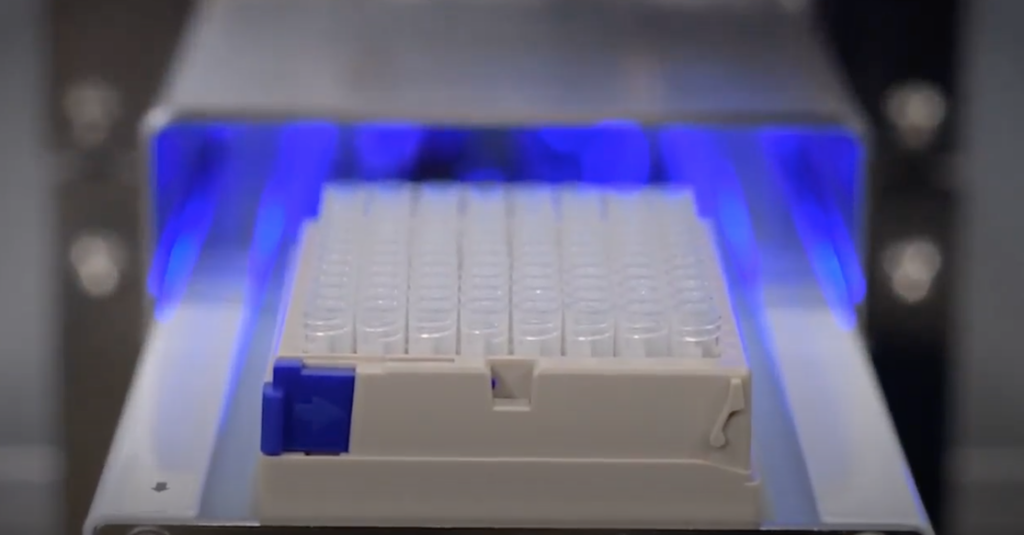

- Aliquoting is performed, filling three tubes with precise volumes.

- Tubes and containers are recapped to ensure sterility.

- Samples are transferred to the next stage of processing.

- Gentle Handling: Careful acceleration and deceleration minimize spilling, maintaining sample integrity.

- Throughput: By processing a sample every 7 seconds across cells, the system ensures high efficiency.

Advanced Features

- Contamination Control: The system was designed with stringent contamination prevention measures.

- Enhanced Traceability: Integrated barcode scanning and tracking ensure accurate sample identification and data management.

- Precision Sensors: Level sensors monitor both the sample and aliquot volumes.

PAR Systems’ automated aliquoting solution demonstrates our commitment to innovation and customer collaboration. From initial prototyping to full-scale implementation, we deliver systems that address the unique challenges of the life sciences industry, providing precision, reliability, and efficiency. Let us help you achieve your automation goals—customized to your needs.

Related Product Information

Contact Us

If you’re interested in implementing this transformative technology in your operations, contact us today!