Waterjet Trimming

Advanced waterjet cutting systems engineered for precision, adaptability, and complex part geometries—delivering clean, high-performance results without heat or tooling.

Producing Highly Contoured Parts of Great Complexity

Waterjet cutting and trimming is a perfect solution when materials are susceptible to distortions from other cutting methods. Suitable for cutting many types of materials, our systems can operate in up to six axes of motion and are designed for a variety of sizes, industries, and applications.

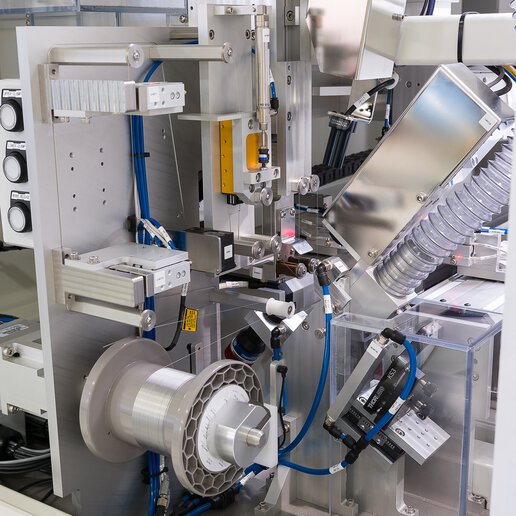

Not Your Ordinary Waterjet

PAR’s adaptive waterjet cutting systems deliver high-pressure plumbing up to 60,000 psi and provide high-precision cutting that is often the primary process for trimming parts.

Our waterjet solutions can be configured for cutting underwater, minimizing noise and improving cleanliness, or fitted with catchers to allow perimeter cutting of parts on integrated configurable fixtures to reduce tooling costs.

Fully Integrated Systems

PAR provides fully integrated systems that include part geometry verification and automated part and tool loading systems. All of our waterjet systems are built with high-pressure intensifier pumps for extreme reliability, and utilize specialty nesting and CAM software to give you the drafting, estimating, programming, reporting, support and maintenance you expect. Water pressure, cutting speed, desired finish, nozzle size, orifice size, garnet and horsepower can be adjusted to optimize your application.

Customized & Configurable

PAR’s waterjet trimming systems are designed and built to each client’s specific needs and applications and are available in variable sizes and configurations. Systems are available both in standard sizes and custom-built sizes including large footprints for unique applications such as commercial aircraft materials.

Optional Add-ons

Optional equipment upgrades that can enhance the functionality of our waterjet trimming systems include:

- Water reservoir

- Chiller for closed-loop cooling

- Self-cleaning tank

- Overflow drain filtration

- Filtration systems for closed loop cutting

- 4-sided enclosures with safety and sound abatement features