Deep Space Exploration

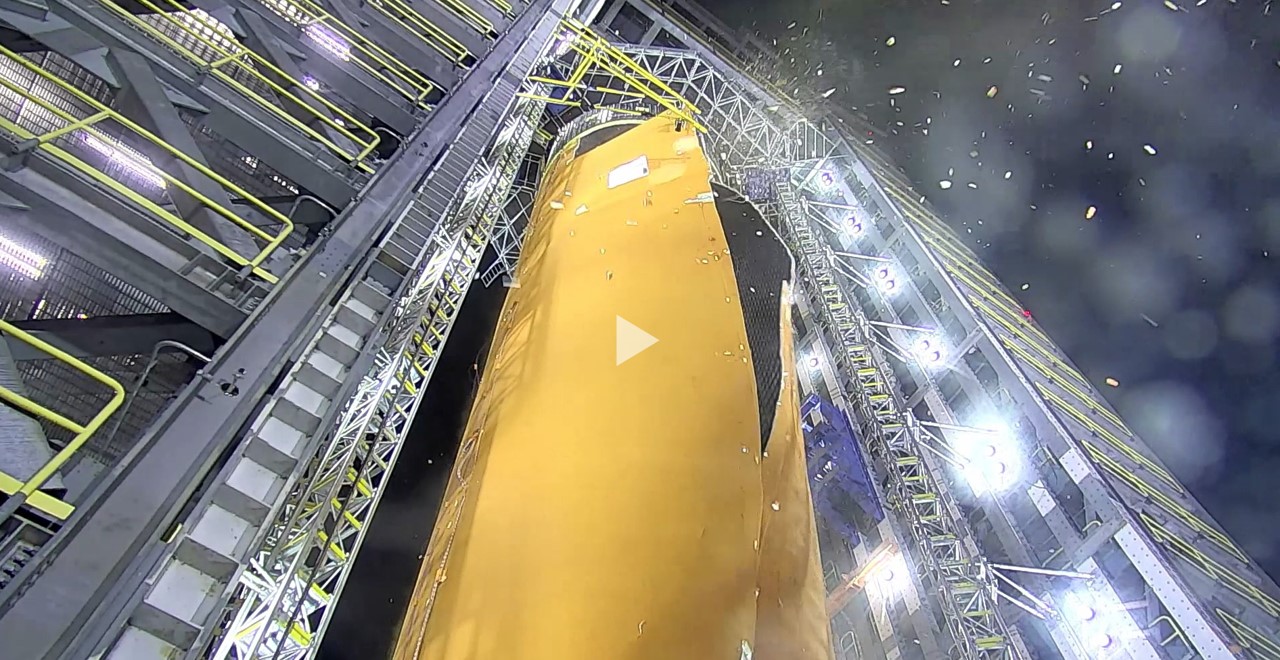

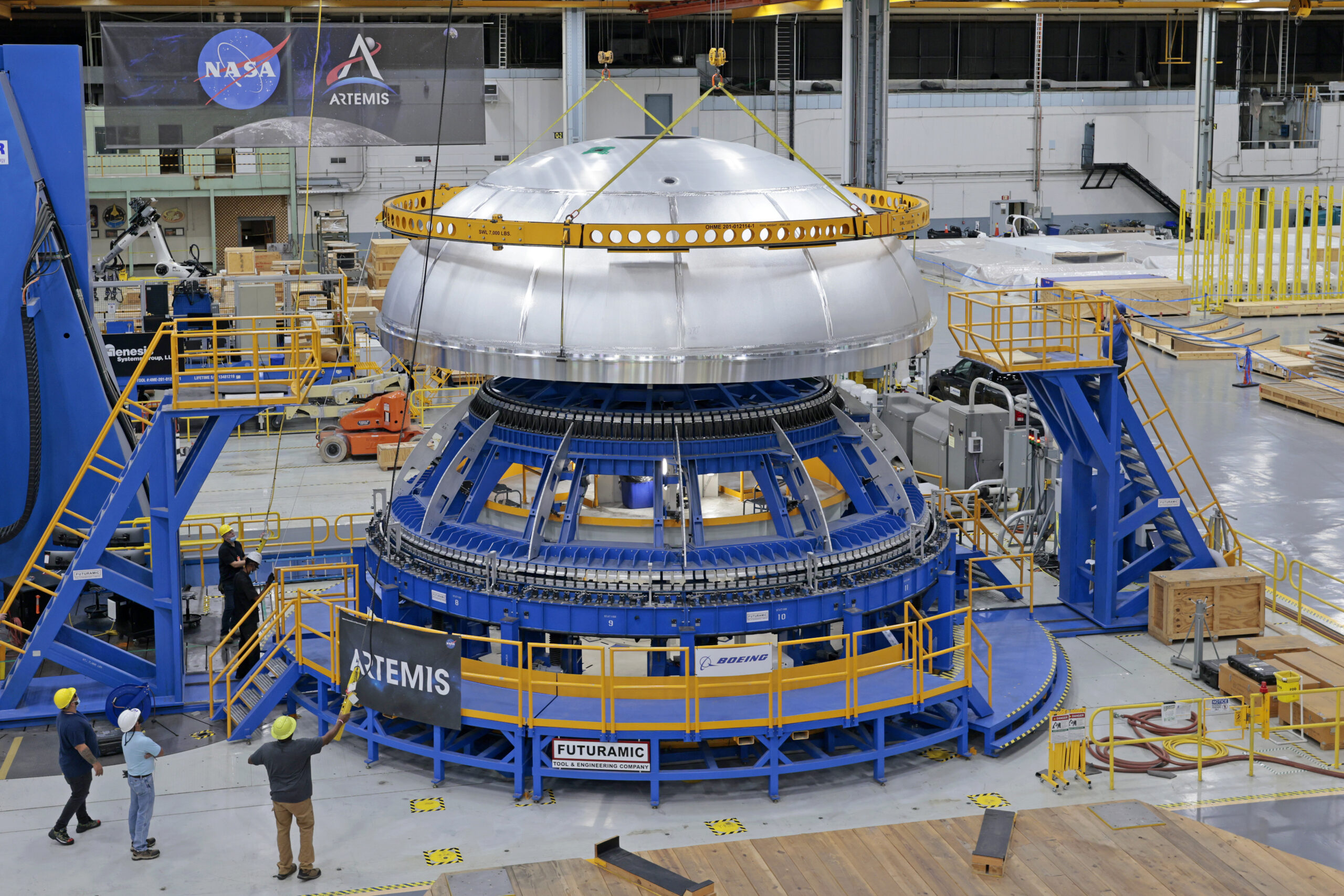

Artemis I

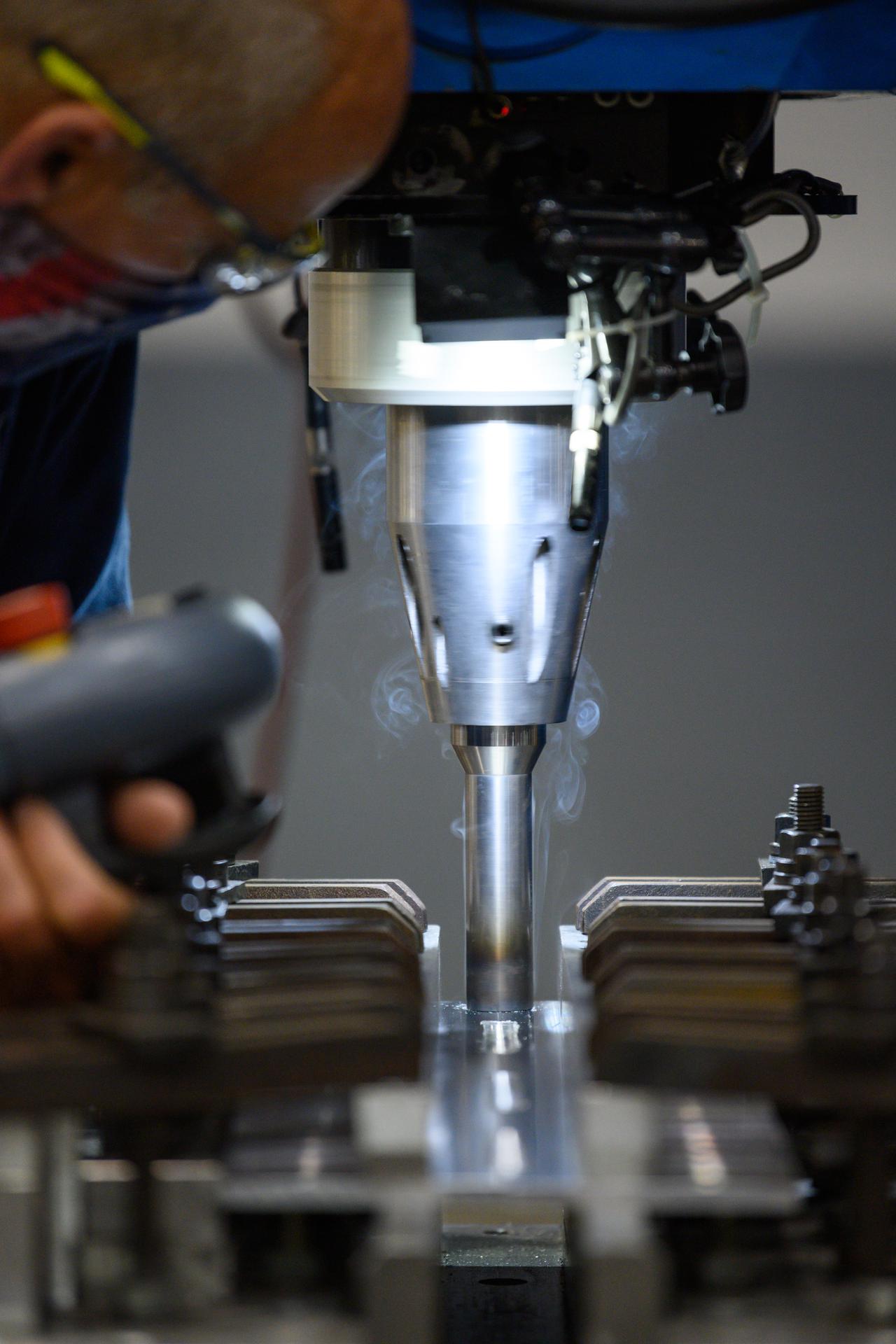

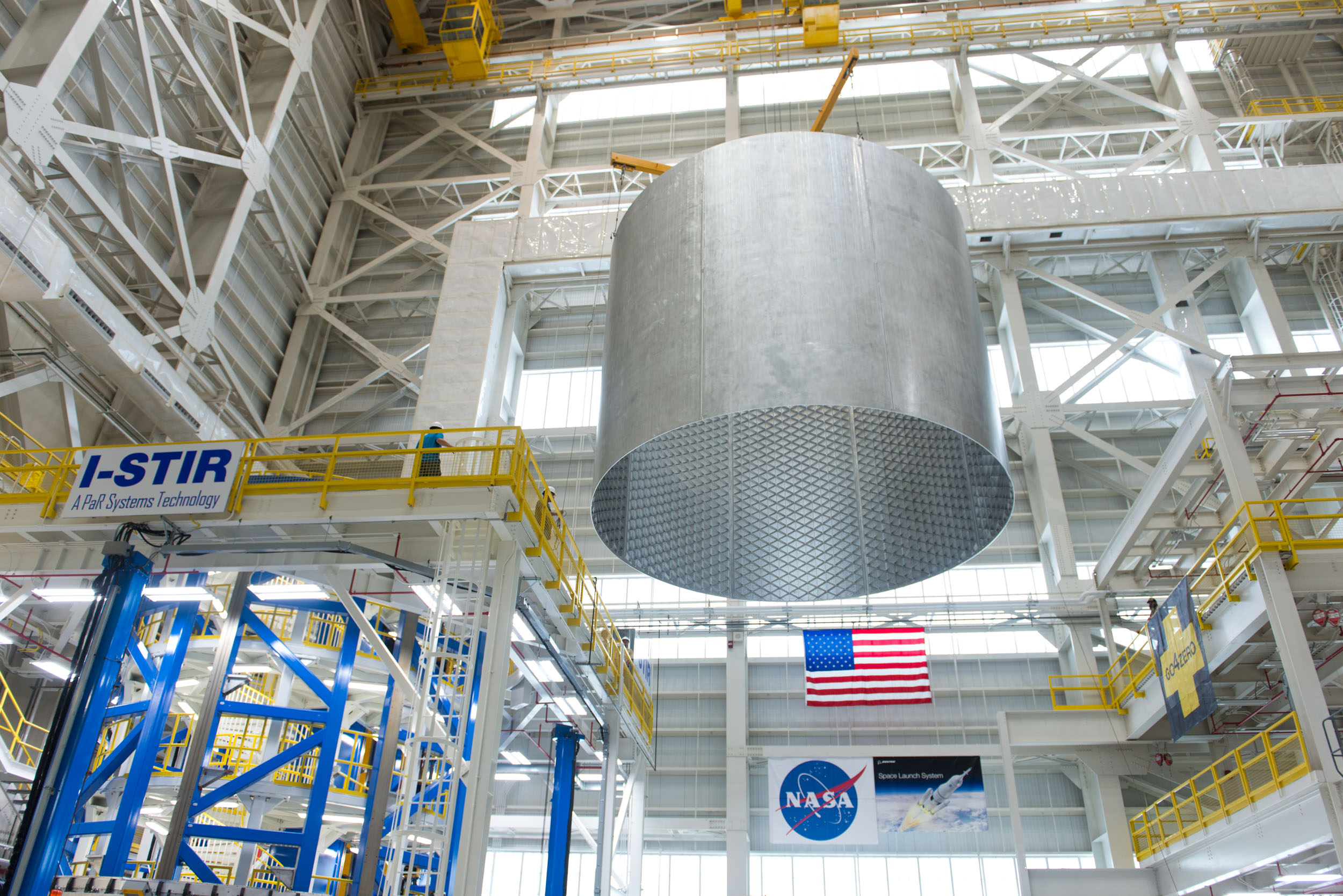

NASA’s Space Launch System is the most powerful rocket ever built and will launch the world’s only spacecraft designed to carry humans to deep space. The launch of Artemis l marks a powerful moment in NASA’s history, and we’re proud to be a part of it.