In The News: PAR Systems Featured for Participation in Artemis l Launch

Jim Freeman, Chief Engineer of Friction Stir Welding at PAR Systems, was interviewed by a local news team to talk about how we supported the Artemis l mission. Jim shares his excitement for Artemis l’s success and for getting to be a part of it.

Watch History In The Making

PAR Systems was featured on the news for our participation in the Artemis l launch.

November 17, 2022

“…And lift-off of Artemis One! We rise together!…”

As NASA’s latest journey into space continues, you can hear the excitement and enthusiasm in Robert Cabana’s voice.

“The launch was absolutely outstanding,” exclaims the 73-year-old NASA Associate Administrator. “It turned night-time into daylight. It was so bright— and it just got up and left town.”

The massive 322-foot Space Launch System Rocket— burning five-and-a-half tons of propellant per second— shot into space at 12:47 a.m. central time Wednesday.

Cabana— who grew up in South Minneapolis, spoke with 5 Eyewitness News about the successful launch, and the mission to come.

He says he saw it all from the roof of the launch control center.

“I’ve seen a lot of launches, and this was better than a shuttle launch,” he says. “It was absolutely amazing. Everything was shaking and vibrating, it’s just an amazing rocket. I’d ride it.”

Cabana has had his share of time in the final frontier.

As a space shuttle pilot, he’s spent 38 days in space.

A journey that began in Minnesota

“I went to Washburn High School, public school,” he recalls. “My grandparents had a farm in northern Minnesota up near Lake Itasca. I spent my summers throwing bales and milking cows and went to school in the cities in the summer, in the school year.”

In the 1960s, he frequented MSP, which, unlike now, was still partly a naval air station, to watch the military aircraft.

A view, he says, that jump-started his dreams.

“I wanted to be a naval aviator,” Cabana remembers. “I wanted to take off and land on aircraft carriers, and I was fortunate enough to get into the Naval Academy and that allowed me to become a pilot.”

As a midshipman in the academy, he saw his first rocket launch in person.

It was enough.

“The physics honor society took a field trip down the Kennedy Space Center to see Apollo 13 launch,” Cabana says. “And I got to see a Saturn 5 take off. I thought, wow, Jim Lovell, Naval Academy graduate, naval aviator, test pilot, astronaut… maybe I could do that.”

Now, decades later, he’s keeping a front row seat as a NASA administrator.

“This is an exciting time for our nation’s space program,” Cabana exclaims. “We’re going back to the moon in a whole new way and a sustainable way.”

Sharing that excitement is Jim Freeman, the chief engineer for the friction stir welding section at PAR Systems in Shoreview.

“Been a lot of fun and a long time coming,” he smiles. “It’s pretty cool to see.”

He says the company has been working with the Artemis project for 11 years.

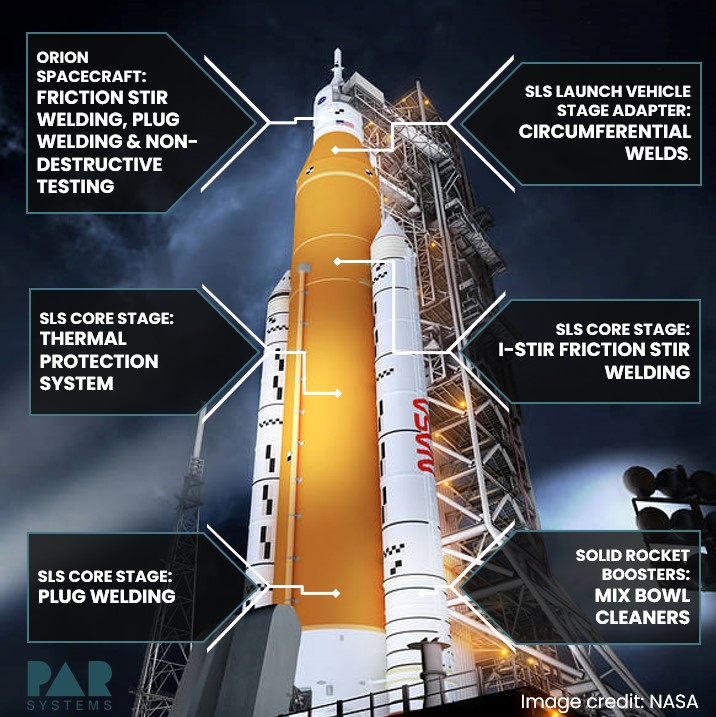

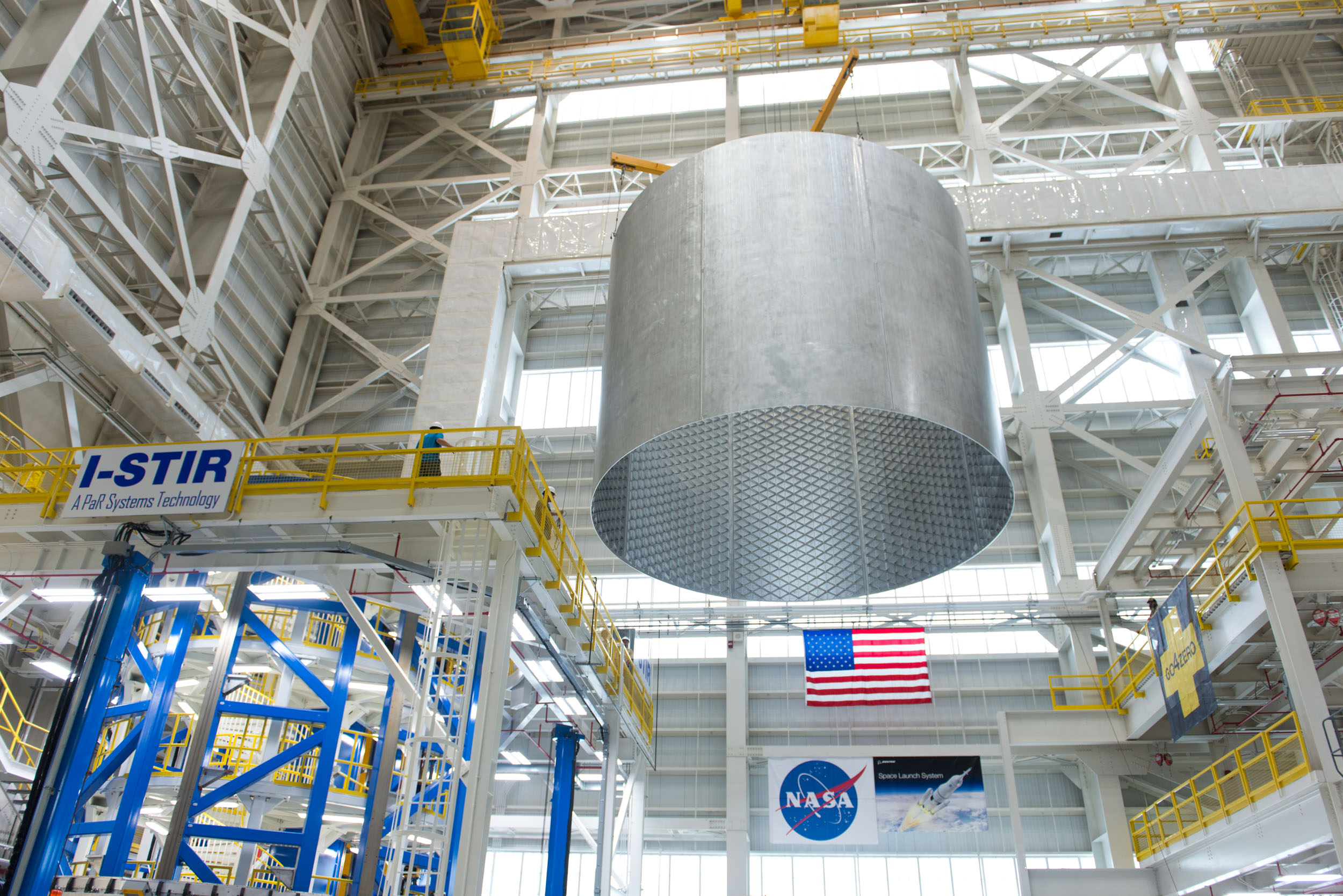

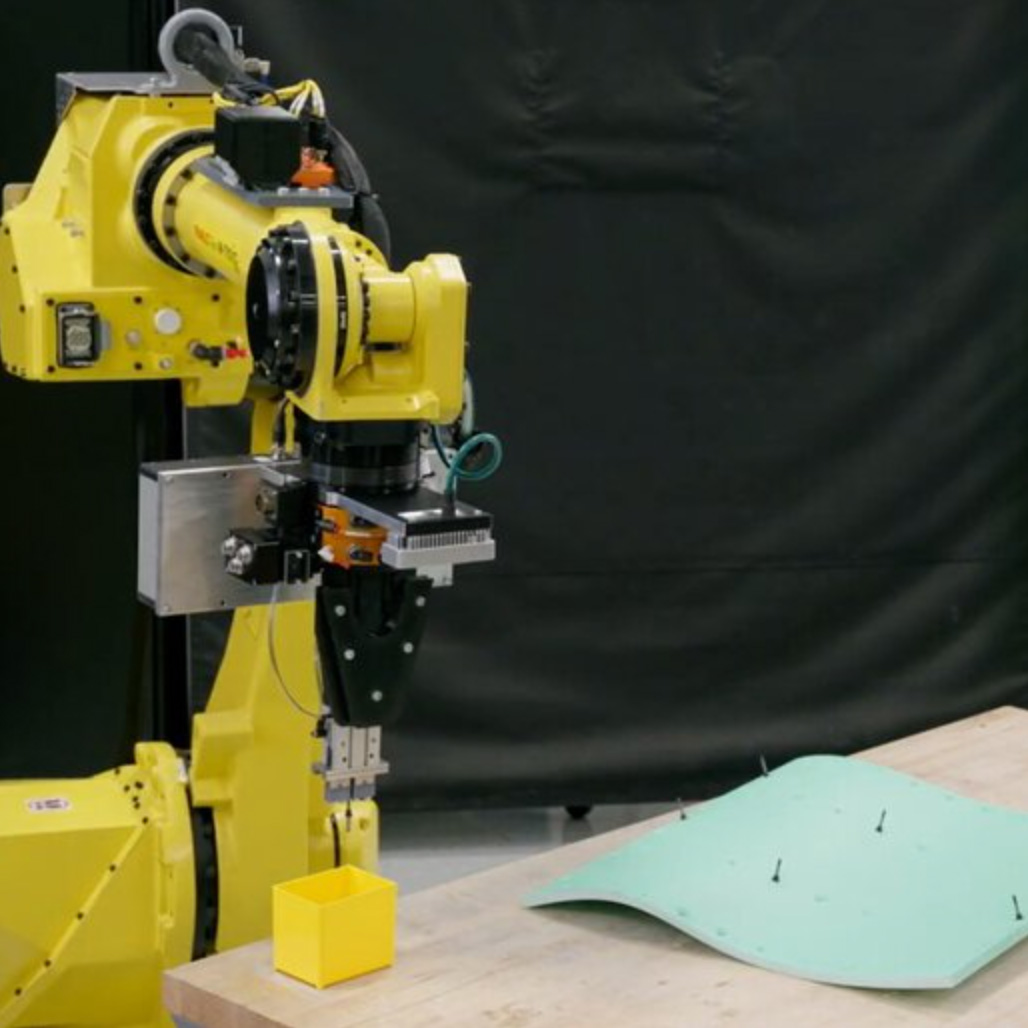

PAR Systems provides equipment and support for aluminum welding work on Artemis’s fuel tanks and the Orion capsule, and foam protection for those tanks.

“The fuel is cryogenic so it’s very, very cold temperatures to hold up to,” Freeman notes. “Those temperatures, and the high stress conditions… and aluminum is very good at doing that.”

Those high stress conditions include nearly nine-million pounds of thrust at liftoff.

The Space Launch System rocket itself weighs 5.7-million pounds.

Then there are the liquid hydrogen and oxygen fuel tanks, with temperatures hundreds of degrees below zero.

The rockets below them can reach 6000 degrees.

“This thing’s gigantic, it’s filled with fuel, liquid, right?” Freeman says. “It’s 300 feet tall, 30 feet in diameter.”

Meanwhile on board— inside the Orion capsule— are several high-tech mannequins, equipped with sensors to test for radiation, vibrations, and other issues that could affect a human crew.

“They’re actually recording the radiation environment that the astronauts will see when they fly in Orion,” Cabana explains. “We’ve got an experiment on board where we actually give voice commands to the capsule.”

NASA acknowledges the Artemis mission is not cheap.

The price tag is about $4-billion per flight.

The space agency says the unmanned Orion spacecraft will fly within 30 miles of the lunar surface, then use the moon’s gravity to fling itself into what scientists call a ‘distant retrograde orbit’— at one point some 298,565 miles from earth.

That’s the furthest a spacecraft designed for human crew members has flown into space.

Orion is expected to splash down in the Pacific Ocean, off the coast of San Diego, on December 11th.

But first— part of the testing will involve the spacecraft’s heatshield, which could reach 5000 degrees during re-entry into the atmosphere.

“The new heat shield is a different design, and we’re going to be coming back at a much higher speed, lunar re-entry velocity,” Cabana notes. “So it’s going to be key that it operates safely.”

Orion’s next journey, in 2024, will have a human crew aboard, with the goal of a third mission, landing two people on the moon sometime before 2030.

The pair of astronauts— who have not been selected— would be the first to land on the moon since 1972.

Cabana says this is just the beginning.

“All of this is in preparation for us eventually going to Mars,” he says. “We’re going to have a whole new generation, the Artemis generation, and it’s going to be awesome.”

Source: KSTP Eyewitness News.com

Image credits: NASA