NASA’s SLS Artemis Moon Mission and PAR Systems’ Specialized Cranes

NASA’s SLS Artemis Moon Mission and PAR Systems’ Specialized Crane Systems

December 1, 2022

Building a rocket is incredibly complicated and requires lots of critical lifting operations of heavy, high-value materials. Several of the specialized crane systems used to support NASA’s Artemis program were built by PAR Systems. Our cranes play a critical role in the production of this spacecraft and are utilized in many phases of the rocket’s production, most notably for stacking of the final rocket assembly, but also for hoisting of various stage assemblies and testing of NASA’s Space Launch System (SLS) rocket systems for the Artemis mission throughout the manufacturing process.

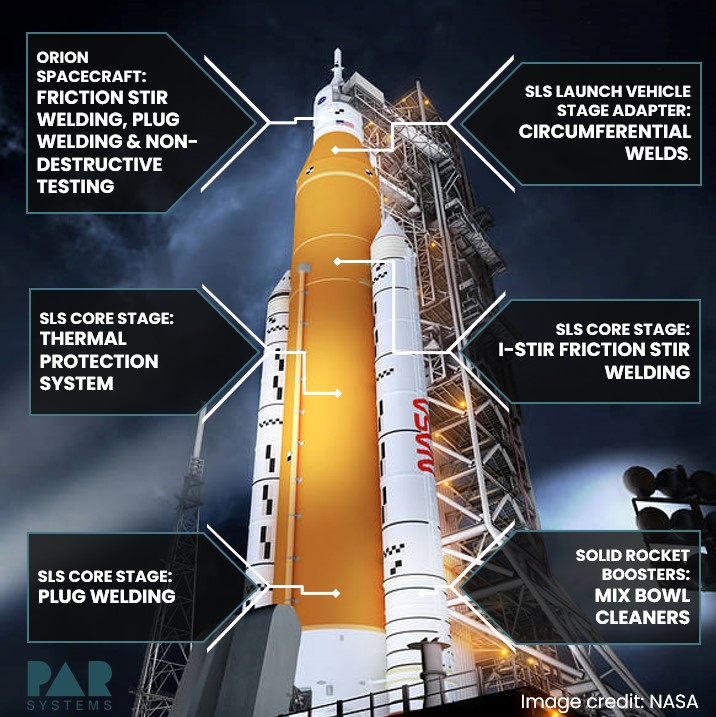

So, what goes into the making of the Space Launch System (SLS) rocket and it’s Orion spacecraft? The SLS rocket consists of a multitude of components including its core stage, solid rocket boosters, stage adapter, engine, propulsion stage, the Orion crew module, service module, and various other components and adapters. Many of these components are extremely heavy, massive in size and require complex lifting and maneuvering techniques throughout the rocket-building process. That’s where PAR’s specialized crane systems come in.

(Article continued after image below)

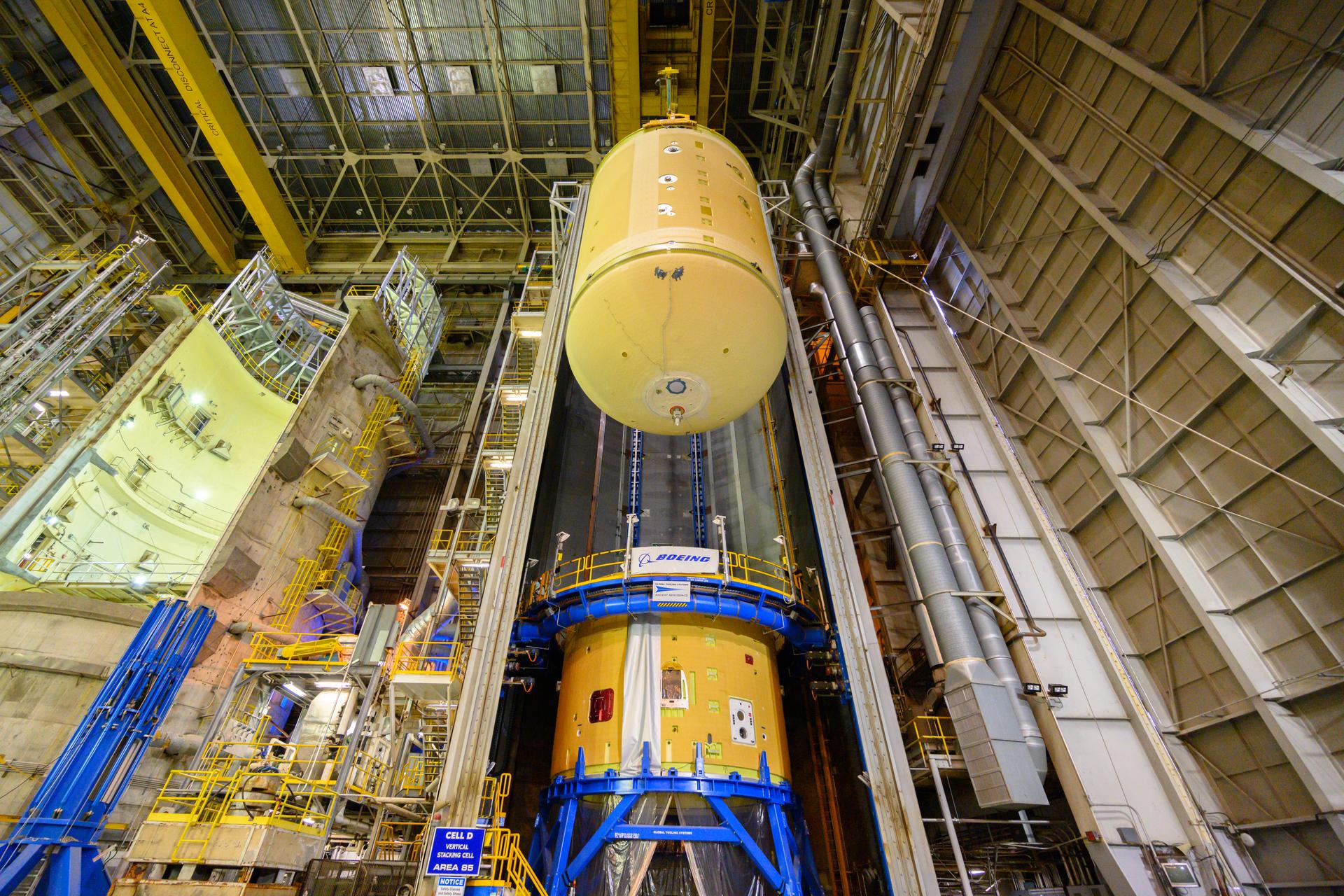

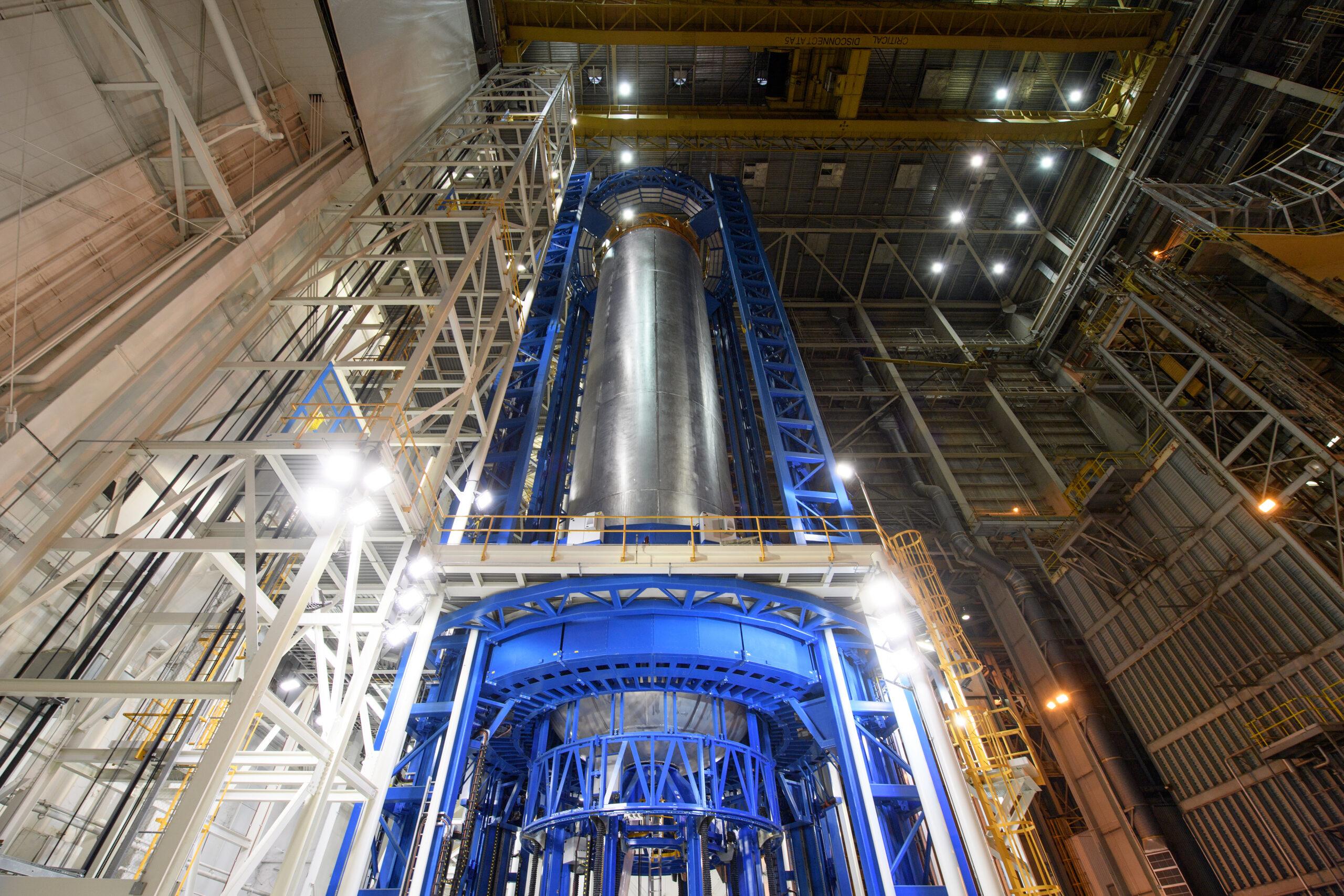

NASA’s Vehicle Assembly Building (VAB) is where several sub-assemblies of the SLS rocket for the Artemis mission are put together for final assembly. The main overhead crane at the VAB of NASA’s Kennedy Space Center is a PAR Systems crane and is used to perform the final rocket assembly and payload canister hoisting. This main crane at Kennedy Space Center is a 325-ton bridge crane with a 50-ton auxiliary hook and is used to lift the massive rocket stage components from horizontal to vertical positions and stack them into position for the final rocket assembly. This main crane can lift NASA’s rocket components 462 feet high, that’s more than 2 airplanes stacked end-to-end on top of each other! It’s what puts all the pieces of the rocket together and is capable of lifting the entire rocket onto its crawler which brings the rocket from the VAB out to the launch pad. Once fully assembled, NASA’s SLS rocket stands 322 feet tall and weighs 5.75 million pounds!

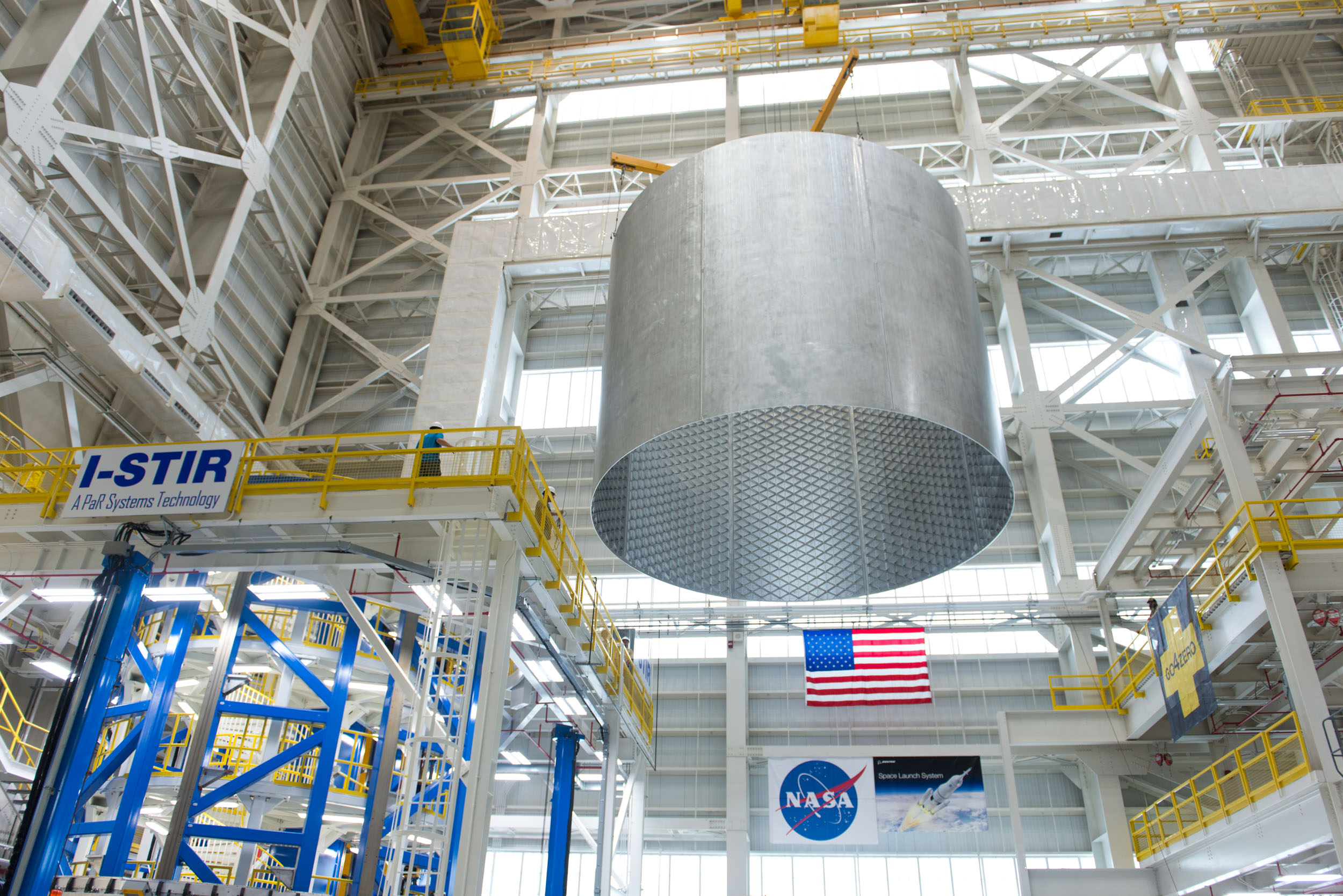

NASA’s Michoud Assembly Facility (MAF) in New Orleans, LA is another major production facility that involves SLS’s core stage assembly. There are two primary PAR cranes used at this facility in the rocket’s production process. These overhead cranes are both 75-ton capacity cranes with 12-ton auxiliary hooks, equipped with our special X-SAM safety system and can lift rocket components 172 feet high, that’s more than 5 school buses stacked on top of each other! These cranes are frequently used for the lifting operations needed to move parts in and out of friction stir welding machine operations of the rocket’s fuel tanks and core stage components and are at times used jointly when lifting the rocket’s massive fuel tanks and re-position them for transport. This tandem operation involves hoisting both ends of the tank and maneuvering from a vertical to a horizontal position, before they are moved onto a transport crane, which moves the tank to other NASA facilities, to begin the next stage of production.

Some of these transport cranes that NASA uses are also built by PAR Systems. These cranes carry fuel tanks and rocket boosters from building to building throughout the rocket’s production process. In the case of the rocket boosters, they are transported by crane from one assembly location, to another facility location where the boosters are hoisted to the vertical position so the propellant can be inserted.

Our cranes also do complex lifting and hoisting of the SLS’s Solid rocket boosters. These cranes enable the production and assembly of the various stages of the solid rocket boosters and its hot fire testing. PAR’s crane for the solid rocket booster production is a 200-ton capacity with a unique 2 trolleys, 2 hook configuration which make complex hosting and maneuvering possible. The extremely critical solid rocket boosters are moved from a horizontal to vertical position for propellant insertion. Our cranes are outfitted with special fixturing and a special safety system allowing the cranes to perform complex maneuvers. PAR also specializes in building cranes necessary for complex and challenging environments. The solid rocket booster cranes were designed to operate in a Class 1 Div. 1 environment. PAR cranes are used to move the rocket boosters into their test fire stage. This ensures that the rocket boosters will be properly positioned to fire successfully.

Tim Flacco, Field Service Technician for PAR Systems has worked with NASA and their contractors in support of the Artemis and Shuttle programs for the past 15 years. Tim has done work on PAR’s cranes that assemble the SLS solid rocket fuel boosters and on PAR’s cranes that assemble the main stage of SLS at NASA’s Michoud Assembly Facility. Tim shares, “Our crane system assembled the Space Shuttles, and now Artemis in the VAB at Kennedy Space Center. While I never grew up to be an astronaut like every other child dreams to be, as an adult by working for PAR I get to be part of the greatest endeavor mankind has ever undertaken. It’s an honor to be even a small piece of history.”

PAR’s X-SAM Safety System Technology

Cranes used for NASA’s Artemis program carry many incredibly heavy, high-value and highly sensitive loads, so it is of the utmost importance they are built with back-up systems to prevent failure or an accident.

One of the technologies that make PAR’s cranes unique is they are outfitted with our X-SAM® technology, a specialized single-point failure-proof safety system. This patented technology is a safety monitoring system that protects the crane hoists from failing which can prevent an accident that could cause a crane from dropping its critical load. It contains an emergency drum brake system, rope spooling monitor and drive train failure detection systems.

If a part of the crane such as the cable shaft, coupling or gear teeth were to break or malfunction, our X-SAM will sense the break-away and will activate the special drum brake safety system to save the crane’s payload from free-falling. X-SAM will also sense if the crane is experiencing a slip clutch due to carrying a load that is too heavy or a two blocking, it will deploy a special brake system, safeguarding the critical load. X-SAM technology has a dual wire rope, each of which can handle the full load if one were to malfunction, and X-SAM will also prevent crane failure due to an overwrapped drum or a drum releasing too fast by activate speed control to protect a critical load.

Learn more about our specialized cranes.

Crane Controls and Capacity Upgrades

PAR has upgraded drives and controls of many of these cranes used for NASA’s Artemis mission. Crane upgrades are sometimes necessary to integrate enhanced technologies or safety systems, or when parts or controls may no longer be available.

Aging overhead cranes built may not be able to meet current production requirements. Whether this is a result of excessive equipment repair downtime, maintenance downtime, or simply from the crane’s own operational performance inefficiencies, these are often the primary drivers when considering whether it is time to modernize your crane.

Ederer cranes was acquired by PAR Systems in 2003. These crane systems used to support NASA’s Artemis program were originally manufactured by Ederer and Colby cranes which were acquired by PAR Systems. More information about PAR’s crane systems is available here.

Learn more about our crane uprate and upgrade services.

Field Service Support and Maintenance

PAR is a long-term partner with all of our customers, including NASA and we are continually supporting our crane equipment used for the Artemis mission by performing service and maintenance when needed. PAR’s service team are experts in keeping your equipment up and running. We can help our customers keep their equipment up and running with spare parts needs, equipment upgrades or replacements, install and training services, and performance assessments when needed. Our goal is keeping operations up and running and when our team is well versed with operations are as critical as a NASA space launch mission, the reliable service of PAR Systems is support our customers can count on.

Learn more about our service team.

Multi-Functional Systems

Not only does PAR specialize in designing and building of specialty crane systems, we’re also experts at engineering multi-functional automation systems that integrate multiple processes in one machine, which can enhance the overall value, production efficiency and bottom-line impact to manufacturers, such as those in the space industry. An integrated multi-process automated system minimizes the number of times a rocket component need to move in the production process.

Utilizing our complex and incredibly accurate crane and robotic motions systems to integrate multiple production processes in the same machine can keep the same component in the same facility location throughout multiple stages of production reducing risk, time and cost, while increase production efficiency. Some of these systems we’ve provided to support NASA’s Artemis program integrate multiple automation processes, such as cutting and trimming a part to size after it’s been friction stir welded or inspecting the part after it’s been cut or welded.

Learn more about our multi-functional and adaptive manufacturing expertise.

Other Technologies

PAR Systems contributed to NASA’s Artemis mission in more ways than just our specialized crane systems. We also supplied systems that friction stir weld components of the rocket’s fuel tank and core stages together as well as systems that automate the process of applying the protective foam insulation that goes on the outside of the fuel tanks.

Read our other articles about the additional areas of expertise and ways PAR contributed to Artemis.

About Artemis

NASA’s SLS rocket for the Artemis mission is the most powerful rocket ever developed in the world with 8.8 million pounds of thrust produced during liftoff! The Artemis mission begins with Artemis I, an uncrewed flight test for deep space exploration to validate the Orion spacecraft and SLS rocket for the Artemis II mission which will bring astronauts back to landing on the moon.

Artemis I is on a 25-day mission, which launched on November 16th, 2022, that includes a test orbit around the moon. NASA is going back to the Moon for scientific discovery and inspiration for a new generation of explorers. The uncrewed Orion spacecraft of Artemis I will travel thousands of miles beyond the Moon, farther than any spacecraft built for humans has ever flown before!

Artemis II will land the first woman and first person of color on the Moon. The Artemis mission demonstrates NASA’s commitment and capability to extend human existence to the Moon and beyond and to build a long-term human presence at the Moon for decades to come.

Read more about Artemis and PAR’s contributions to this space program.