NASA’s SLS Artemis Moon Mission and PAR Systems’ Friction Stir Welding

NASA’s SLS Artemis Moon Mission and PAR Systems’ Friction Stir Welding

November 23, 2022

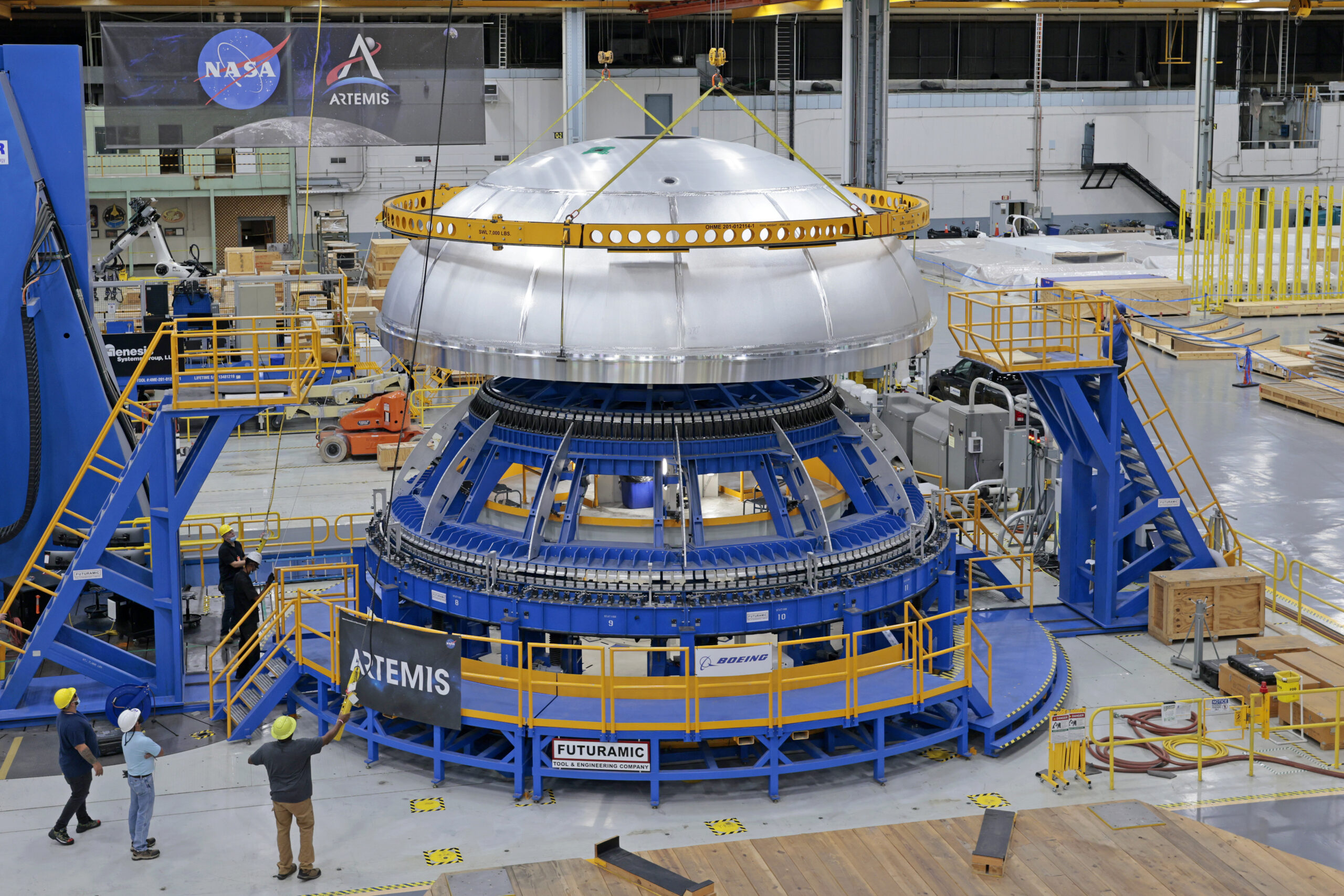

PAR Systems is proud to support NASA’s Artemis program with our Friction Stir Welding I-STIR Technology. Our friction stir welding (FSW) systems played a critical role in the production of this spacecraft, used for welding the fuel tanks of the Space Launch System (SLS) rocket vehicle and the Orion crew capsule.

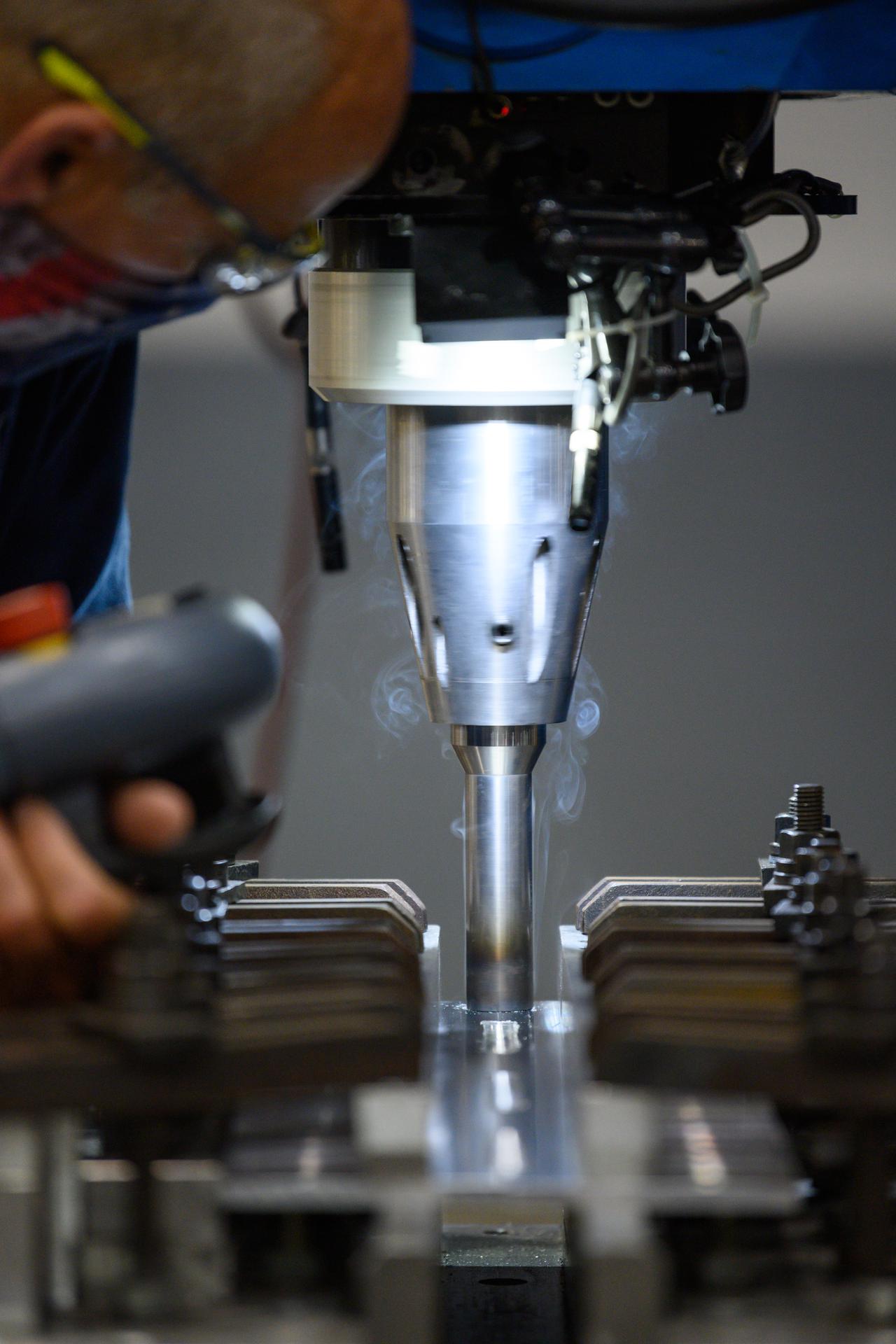

Friction stir welding is often used to weld the critical components that make up the fuel tanks and critical structure of the rocket, because of the superior joining properties of the solid-state process. This process doesn’t add any filler material, so it doesn’t add any weight to the rocket. This is critical to optimizing the rocket’s performance and payload.

(Article continued after image below)

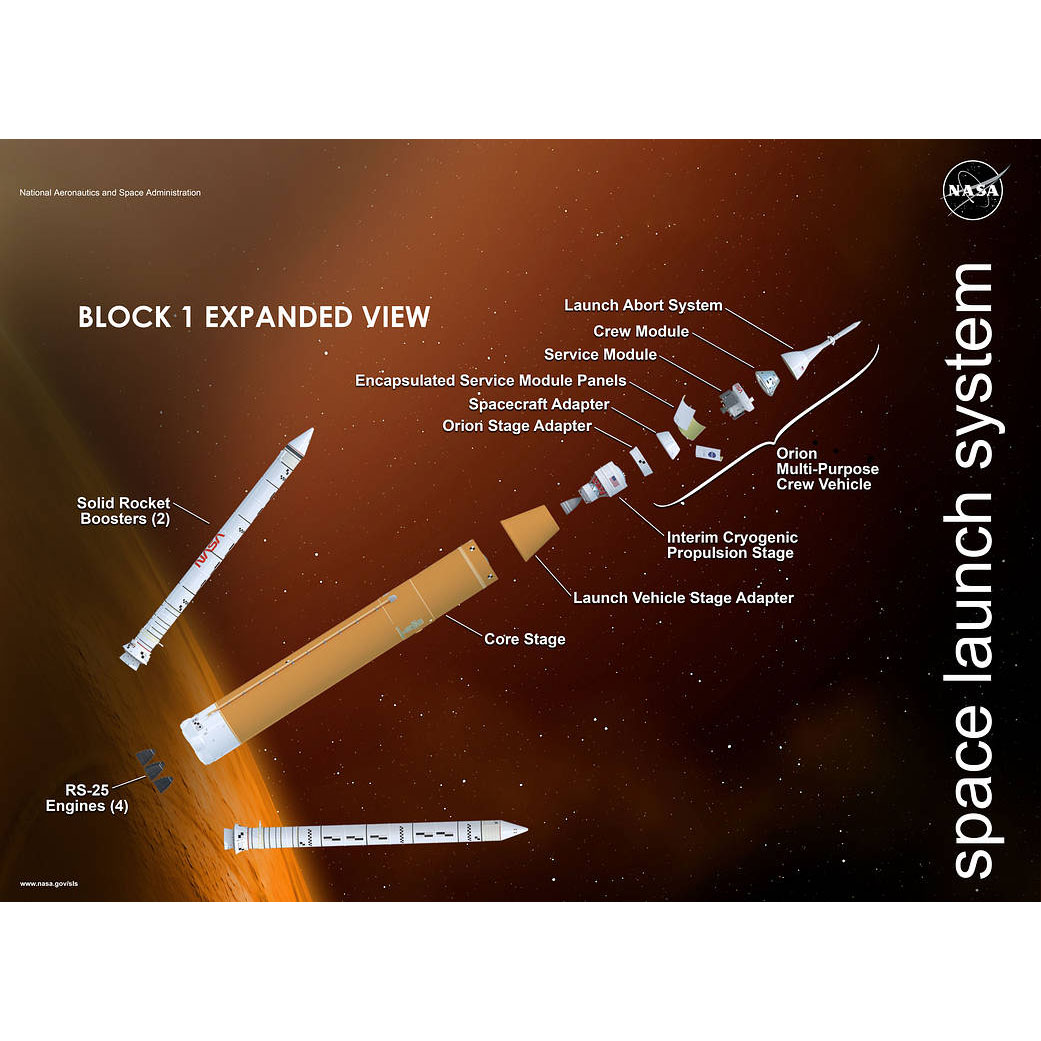

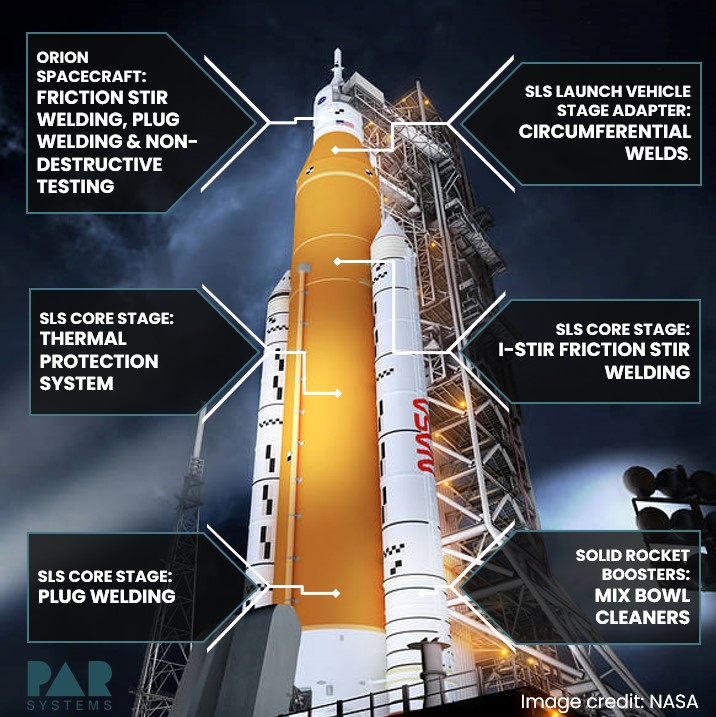

So, what goes into the making of the Space Launch System (SLS) rocket and it’s Orion spacecraft? The SLS rocket consists of a multitude of components including its core stage, solid rocket boosters, stage adapter, engine, propulsion stage, the Orion crew module, service module, and various other components and adapters.

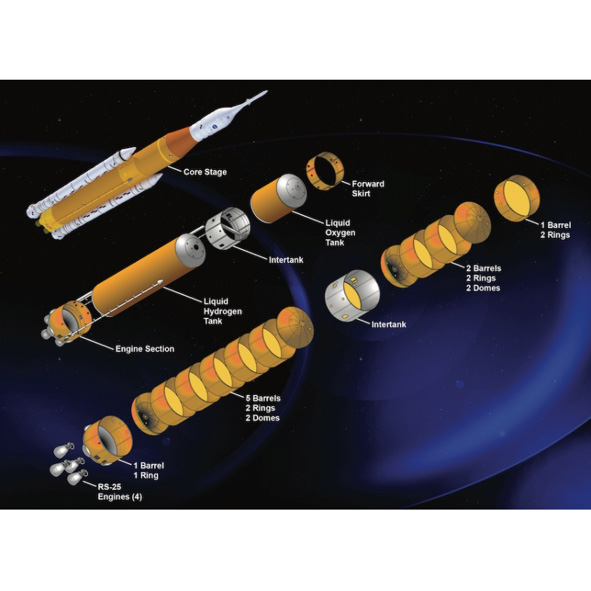

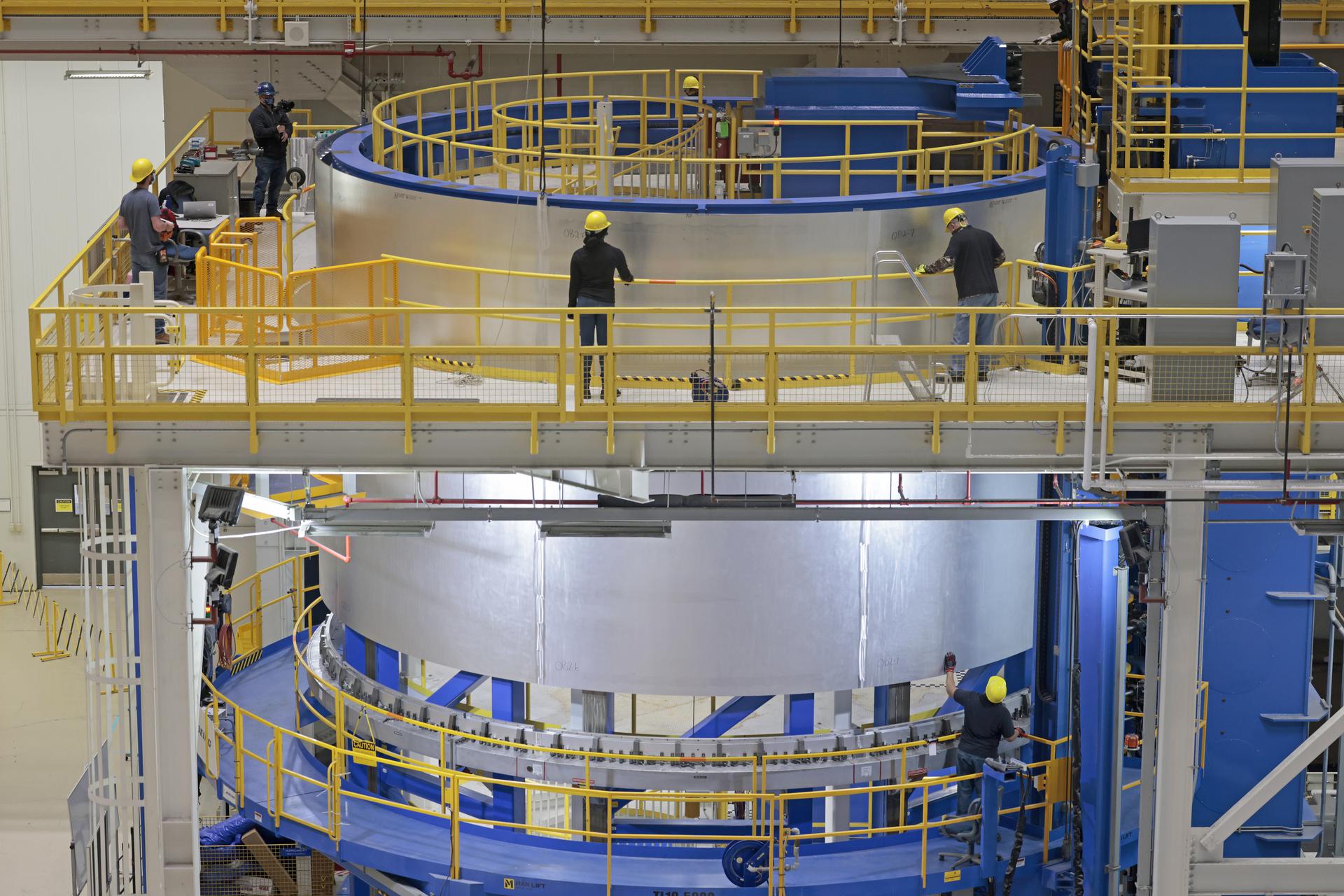

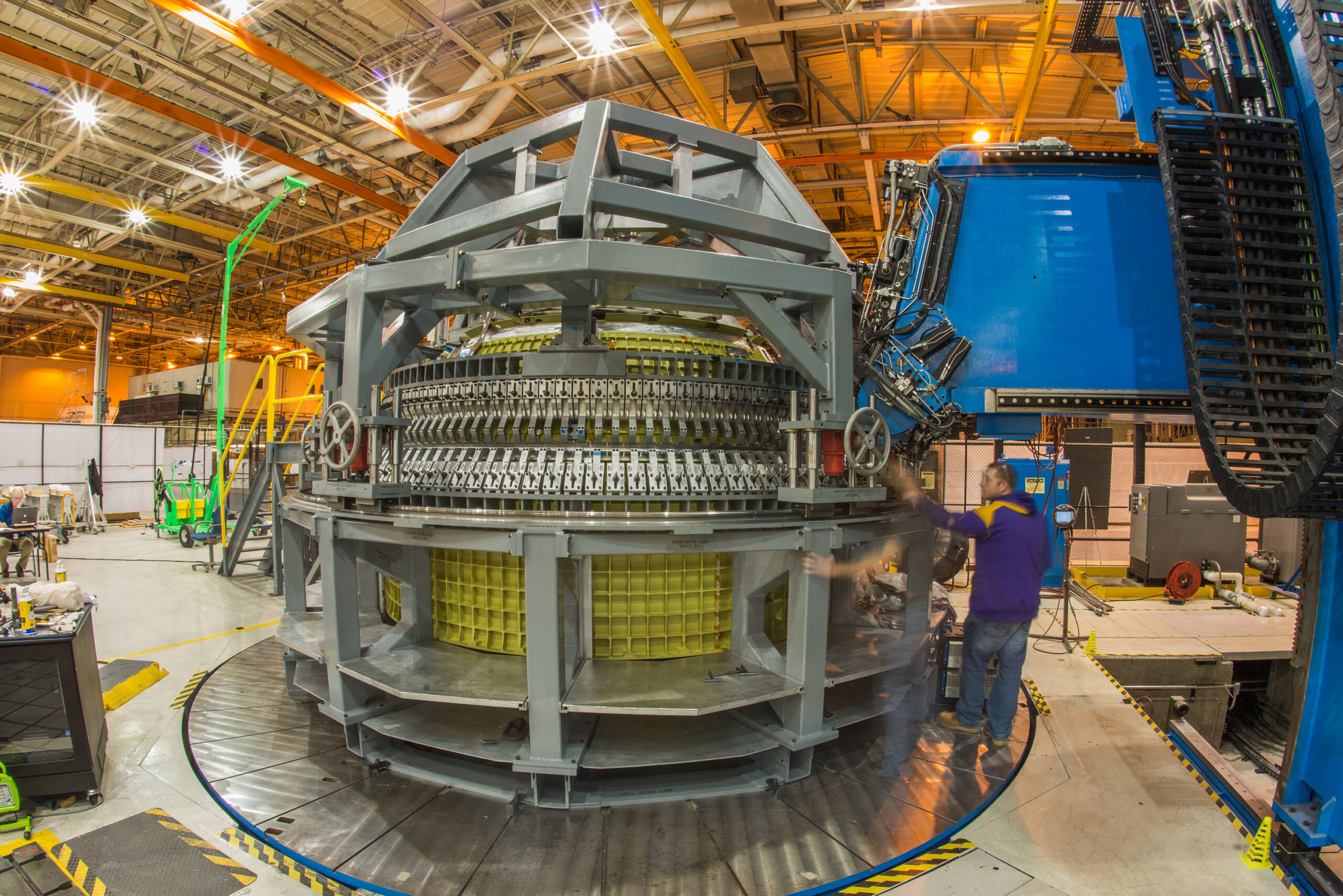

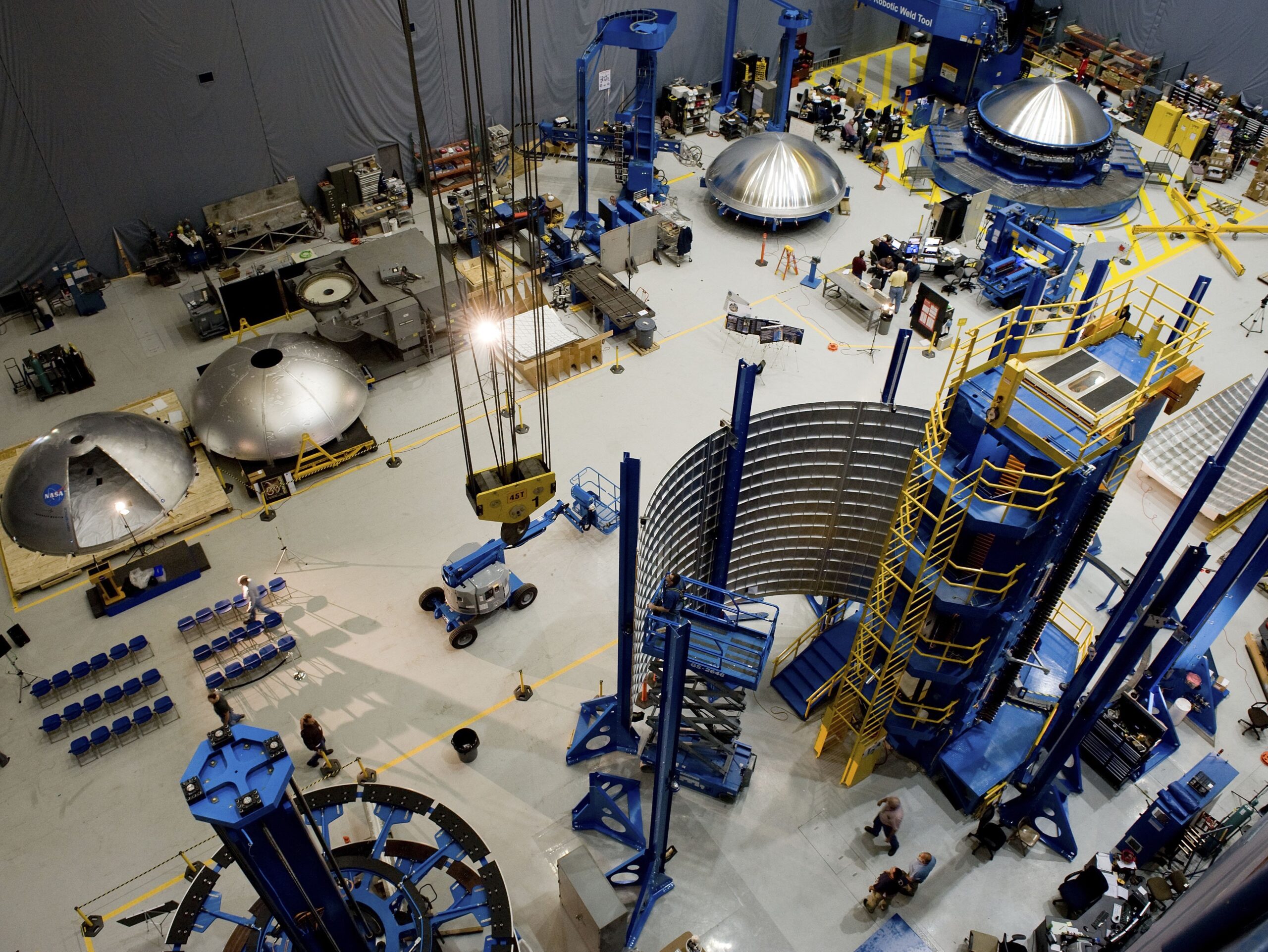

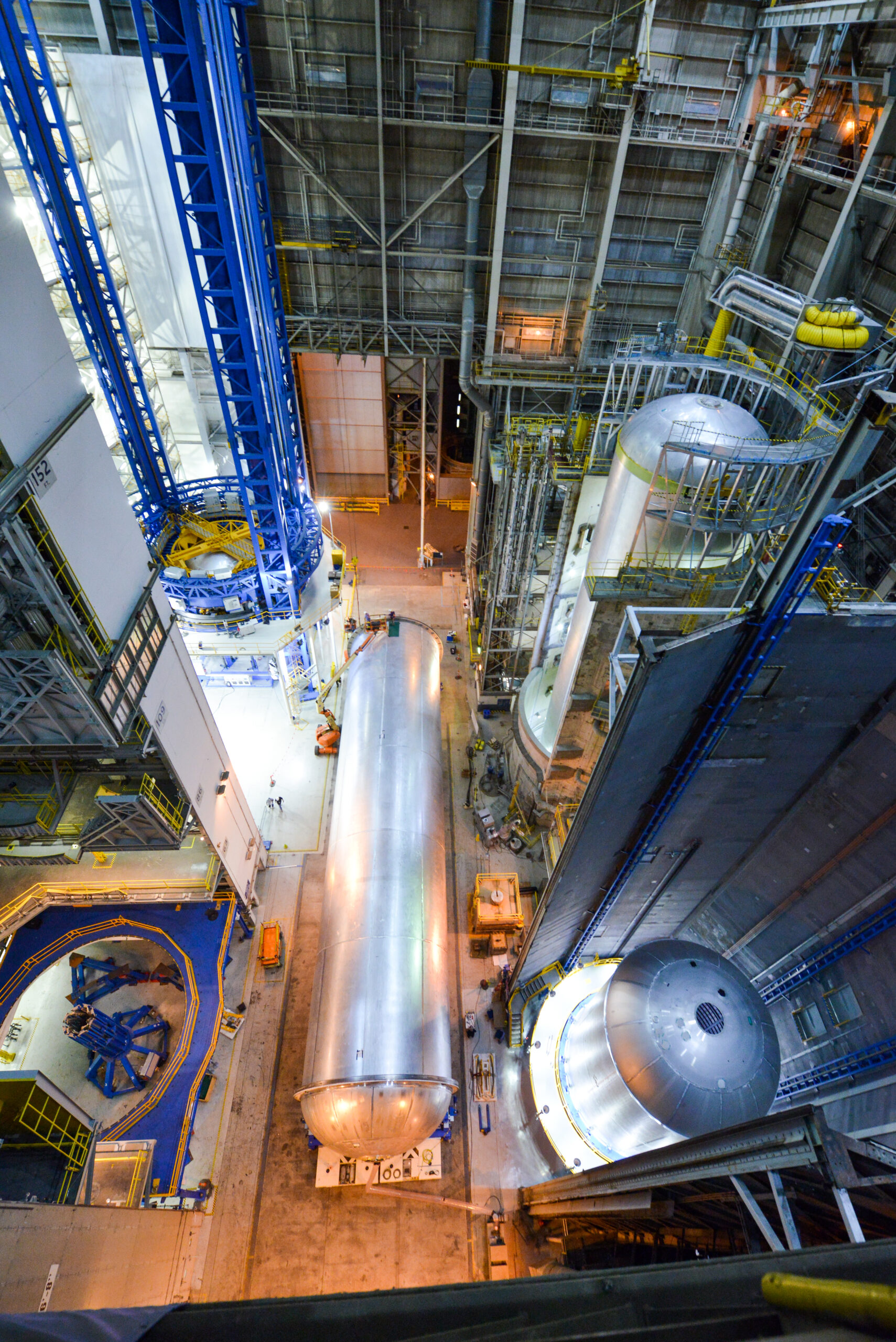

PAR has played an integral role supporting production of the core stage, stage adapter and Orion crew module using our I-STIR friction stir welding technology. The rocket’s fuel tanks are primarily what makes up the core stage of the rocket. Our friction stir welding systems are used in the production of the barrels, rings, domes and inter-tank assemblies that make up the components of fuel tanks of NASA’s Space Launch System (SLS) core stage. For context of size, when the core stage tank is in a horizontal assembly position, it is over 27 feet wide and 212 feet long! That’s as tall as 7 telephone poles stacked on top of each other!

(Article continued after images below)

The fuel tanks are what hold the fuel (liquid oxygen and liquid hydrogren) that enable Artemis’s SLS rocket to launch into space. Without precisely built fuel tanks, the SLS rocket could not have launched into space to carry out the Artemis I mission. The rocket tanks of SLS are comprised of various components including barrels, domes and rings. Even the multiple barrels and domes that make up the fuel tank are produced in panel sections of material that need to be welded together to complete a barrel or dome. PAR’s friction stir welding is used to weld these panel sections together to create these critical fuel tank components.

Our friction stir welding systems contributed these multitude of components that make up the fuel tanks of the Artemis SLS rocket including: vertical and plug welding of the core stage barrels, circumferential and gore welding of the core stage domes, core stage adapter rings and adaptive weld tooling for the launch vehicle stage adapter.

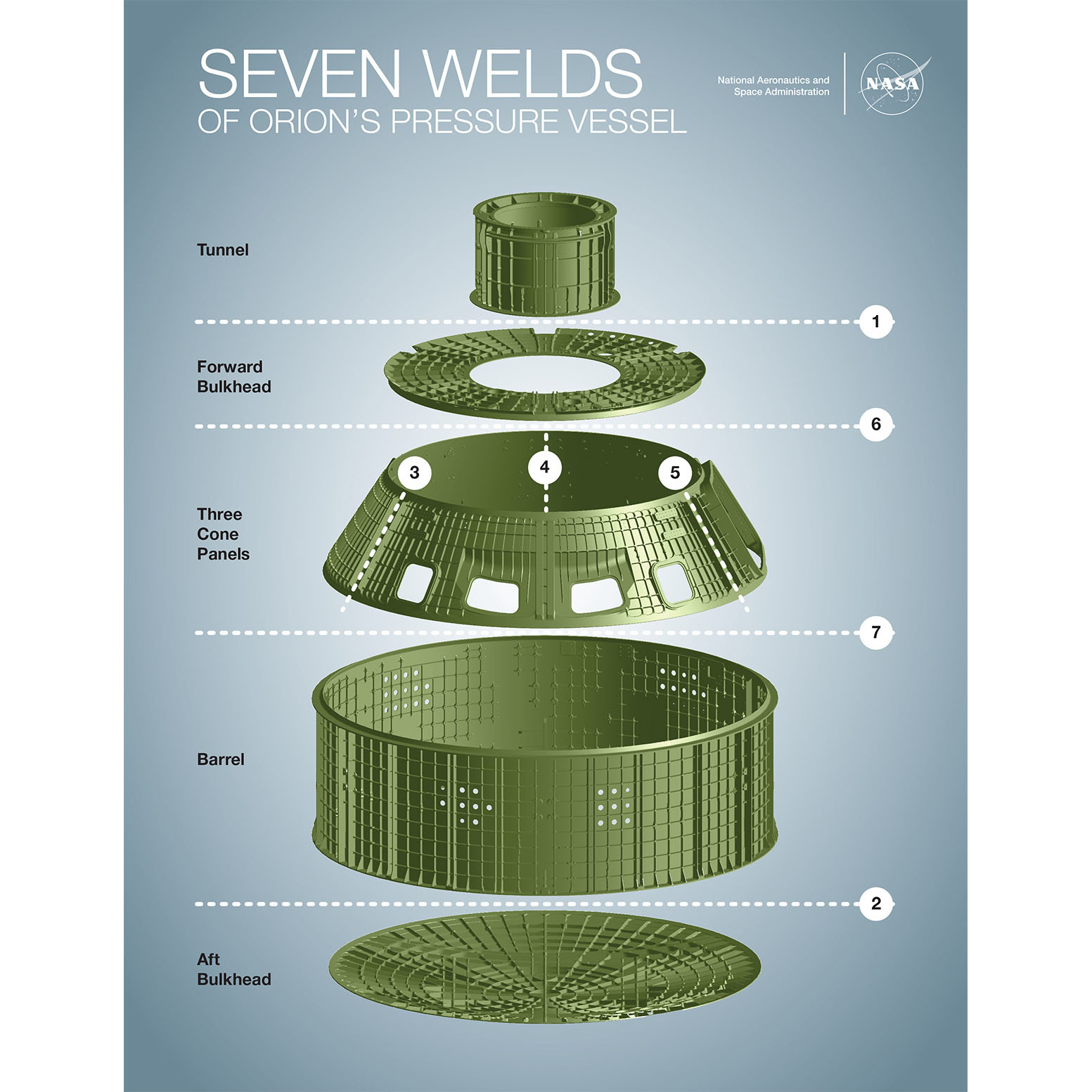

Another major part of this spacecraft is its payload, which for the Artemis mission is the Orion crew capsule. This capsule is what is slated to transport the first woman and first person of color to land on the moon! Our universal FSW and plug welding systems also supported the production of Artemis’ Orion crew capsule.

Jim Freeman, Chief Engineer for Friction Stir Welding at PAR Systems shares, “PAR is proud to have provided our friction stir welding equipment for manufacturing of numerous key components on the Space Launch System (SLS) and the Orion Crew Capsule in support of the Artemis 1 mission. Our friction stir welding and friction plug welding equipment welded a majority of the Core Stage, Stage Adapter and Orion structural components. PAR is proud to have supported our partners at NASA, Boeing and Lockheed and we look forward to continuing to support the future of Artemis launches and our return to the Moon and on to Mars!”

PAR’s Friction Stir Welding and Space

PAR specializes in building friction stir welding systems that produce a superior quality weld in challenging environments and require precise control of large equipment, much like rockets for space missions.

Friction stir welding is the optimal joining process for the welding of fuel tanks on rocket space vehicles for many reasons, primarily because it is a solid-state joining process, which means it does not add any material or weight and it joins two materials completely into one solid material with minimal distortion. What does this mean for space? This means that these tanks sections can be welded together without any added weight and when NASA is launching a massive rocket into space, like SLS for the Artemis mission, weight is critical. Less weight means less fuel required, but more payload availability, which lowers costs (savings which could equal millions of dollars for our space programs). More payload availability can enable the crew to take more materials aboard the spacecraft to support space exploration. All in all, friction stir welding creates a more efficient rocket. This also means that the materials friction stir welded – SLS’s core stage tanks, stage adapter and crew module are of superior quality and strength. Typically, with traditional welding or joining processes, where two materials are welded together creates a weak spot, but because friction stir welding is a solid-state process and joins two materials truly into one material, it creates a super strong and durable structure. This superior quality is of utmost importance when we are talking about materials being launched into space and withstanding the extreme forces that happen in a launch.

Learn more about our friction stir welding expertise.

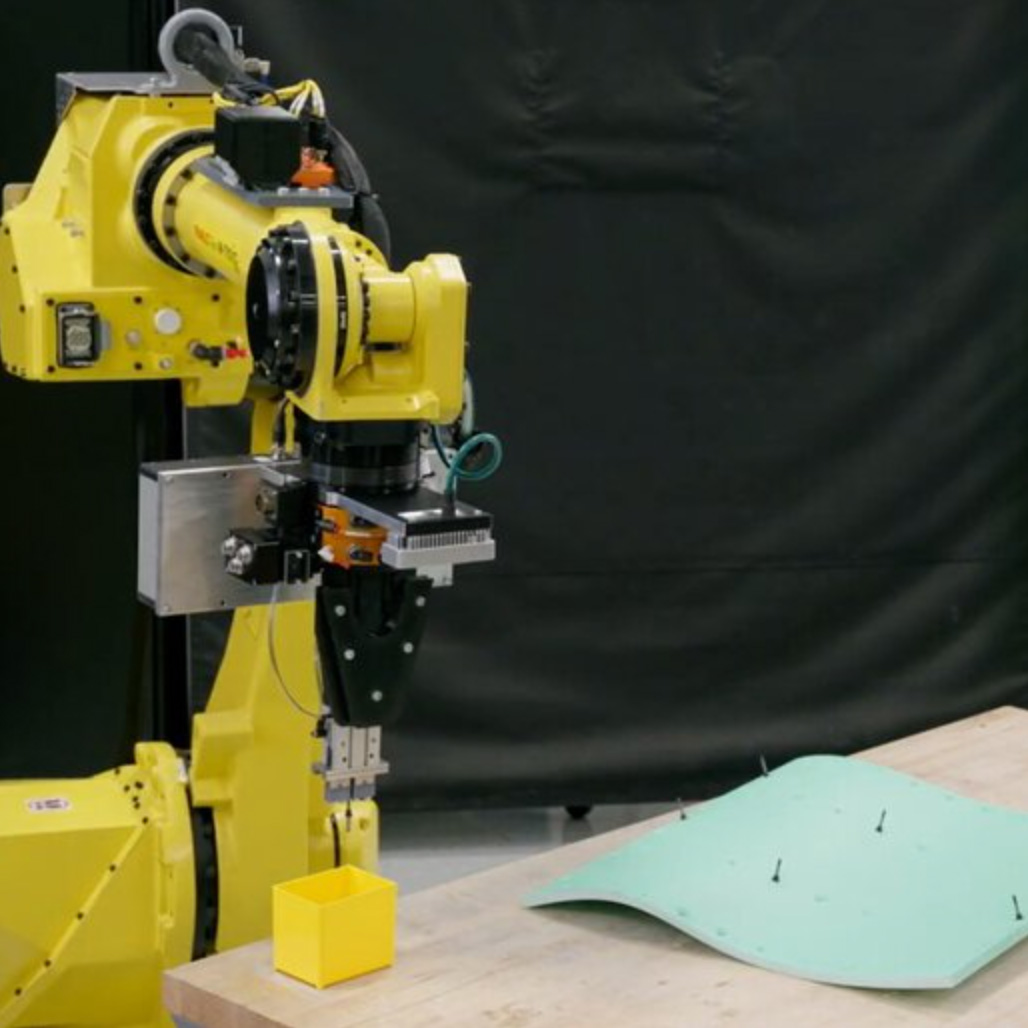

Multi-Functional Systems and Other Technologies

Not only does PAR specialize in designing and building of friction stir welding systems, we’re also experts at engineering multi-functional automation systems that integrate multiple processes in one machine, which can enhance the overall value, production efficiency and bottom-line impact to manufacturers, such as those in the space industry. Some of these systems we’ve provided to support NASA’s Artemis program integrate multiple automation processes, such as cutting and trimming a part to size after it’s been friction stir welded or inspecting the part after it’s been cut or welded.

Learn more about our multi-functional and adaptive manufacturing expertise.

PAR Systems contributed to NASA’s Artemis mission in more ways than just our friction stir welding technology. We also supplied systems that automated the process of applying the protective foam insulation that goes on the outside of the fuel tanks as well as the crane systems that lift many of the rocket parts in both manufacturing processes and that enable the final rocket assembly!

Look for our other articles about the additional areas of expertise and ways PAR contributed to Artemis.

About Artemis

NASA’s SLS rocket for the Artemis mission is the most powerful rocket ever developed in the world with 8.8 million pounds of thrust produced during liftoff! The Artemis mission begins with Artemis I, an uncrewed flight test for deep space exploration to validate the Orion spacecraft and SLS rocket for the Artemis II mission which will bring astronauts back to landing on the moon.

Artemis I is on a 25-day mission, which launched on November 16th, 2022, that includes a test orbit around the moon. NASA is going back to the Moon for scientific discovery and inspiration for a new generation of explorers. The uncrewed Orion spacecraft of Artemis I will travel thousands of miles beyond the Moon, farther than any spacecraft built for humans has ever flown before!

Artemis II will land the first woman and first person of color on the Moon. The Artemis mission demonstrates NASA’s commitment and capability to extend human existence to the Moon and beyond and to build a long-term human presence at the Moon for decades to come.

Read more about Artemis and PAR’s contributions to this space program.