Ultrasonic Cutting & Sculpting

Precision ultrasonic cutting and sculpting systems that boost productivity, reduce tooling costs, and streamline complex processes—fully automated and tailored for high-efficiency manufacturing.

Precision and Efficiency Combined

Cutting of core materials is often a difficult and extremely dusty operation that leaves ragged edges and torn cells. To achieve the precision and cut quality demanded by aerospace applications, without the dust, PAR uses ultrasonic cutting technology.

Contact us to learn more about our ultrasonic cutting technology.

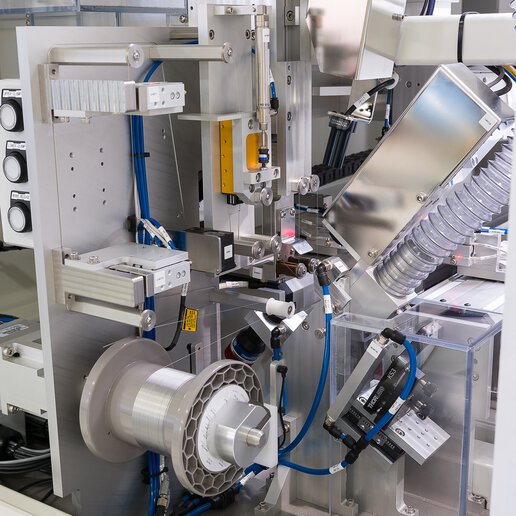

Single-station Cutting Solution

PAR’s ultrasonic cutting systems use both traditional straight knives and rotating discs that expands and contracts at ultrasonic rates to cleanly trim aerospace honeycomb core materials. Whether phenolic, Kevlar, or aluminum core, these machines provide the optimal solution, without dust. To enhance productivity, the machines can also cut pre-impregnated composite material (prepreg), enabling all your cutting operations to be in a single station.

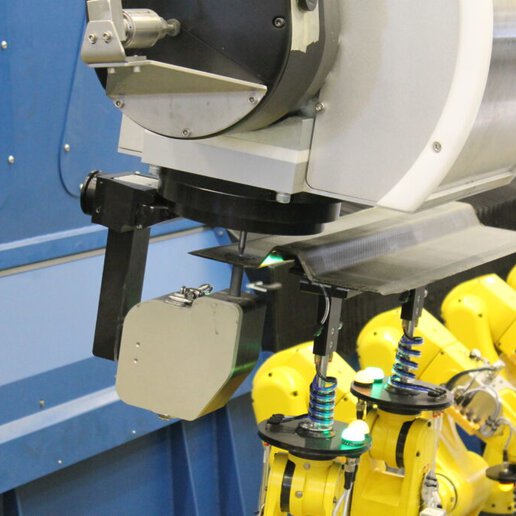

Precision Motion

PAR’s Precision Motion Platform provides the base motion system for the integrated ultrasonic cutting process. The linear motors provide the high speed and high acceleration that this process demands. And if required, a spindle head can be automatically exchanged for the ultrasonic head to provide drilling and secondary milling processes.

Higher Quality & Safety

Ultrasonic cutting virtually eliminates friction in the cutting process, allowing for low-force cutting and higher-quality cuts while producing no dust. Ultrasonic cutting and sculpting can be used on a variety of materials such as composites, preforms, aluminum, and core materials.

No matter the material, we have a system to cut it to exacting standards.

- Composites

- Kevlar

- Carbon Fiber

- Fiberglass

- Prepreg

- Core

- Preforms

- Aluminum

- Titanium

- Glass

- Ceramic

- + More

Related Solutions

Certified in all the right places.