PAR Systems Develops Fuel Removal Machine for Fukushima Daiichi

January 20, 2016

PAR Systems, Inc., a world leader in nuclear decommissioning, robotic manipulators, material handling and automation solutions, in coordination with Westinghouse Electric Company, has developed a remotely operated, submersible tool delivery platform for spent fuel pool debris and fuel removal tasks at the damaged Unit 3 of TEPCO’s Fukushima Daiichi nuclear power plant in Japan.

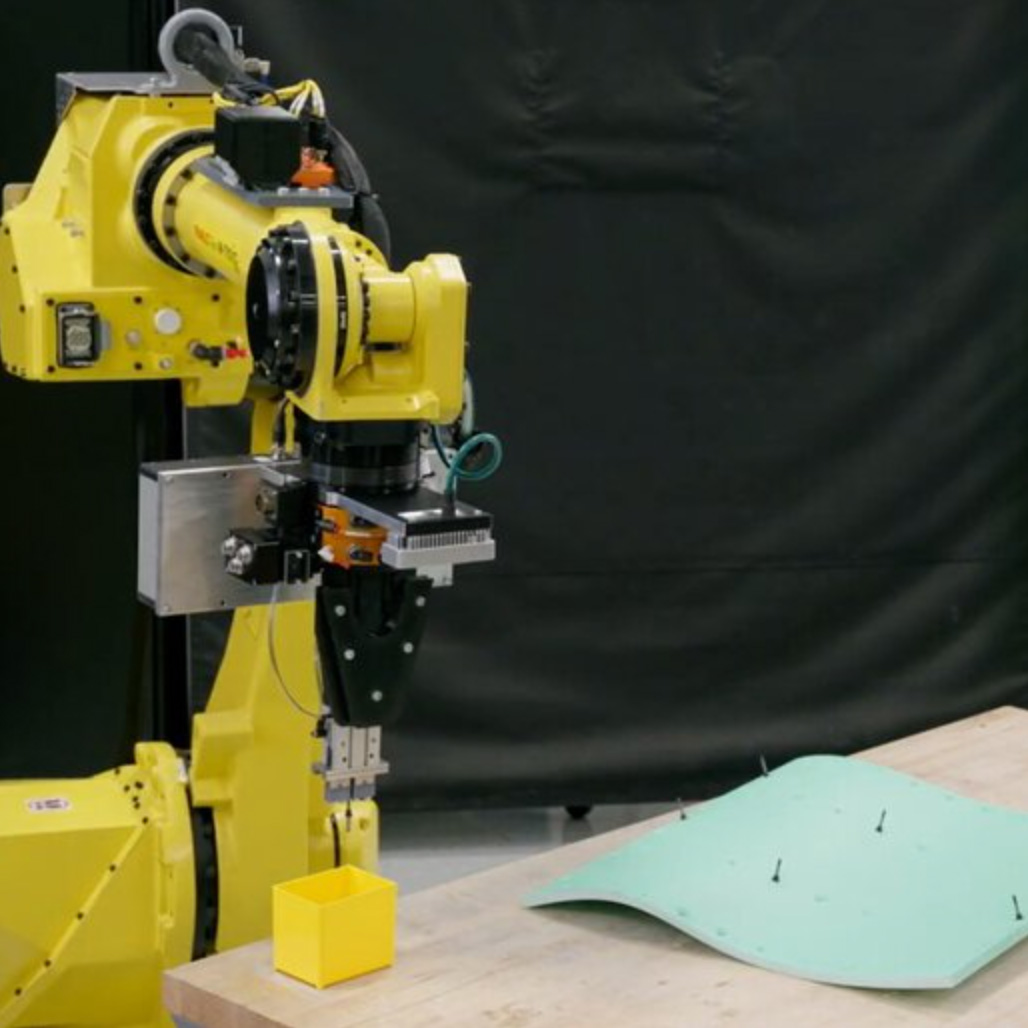

Toshiba revealed PAR Systems’ massive 74 tonne fuel handling machine on January 18th, highlighting this important, ground-breaking technology which will be used to safely remove the contents of the spent fuel pool at the top of the reactor building. PAR Systems’ equipment is a combination gantry crane, fuel handling machine and submersible robotic tool delivery system. The system utilizes PAR’s TensileTruss™ system to deliver Westinghouse provided manipulator arms and tooling necessary for underwater debris and fuel recovery. The gantry and tensile truss equipment were designed to be operated remotely with minimal maintenance required. PAR’s equipment interfaces seamlessly with the equipment provided by Westinghouse to complete the fuel and debris removal system for Toshiba.

PAR Systems is proud to have been entrusted with this important project for the ongoing project at Fukushima Daiichi. PAR has much experience in this type of system development, having built the first remote robotic nuclear crane and tensile truss system for the decommissioning of the damaged Unit 4 at Chernobyl Nuclear Plant in Ukraine as well.

About PAR Systems

PAR Systems, a portfolio company of MML Capital Partners (www.mmlcapital.com), is a world leader in providing advanced intelligent solutions for critical material handling, automation, and robotic applications that drive customer quality, safety, and productivity. Since 1961, PAR has created fully integrated systems, which are often first-of-a-kind manufacturing solutions, for a broad range of industries including aerospace, hazardous material/nuclear, life science and process automation, marine/defense, heavy material handling, and industrial. Headquartered in Minnesota, PAR Systems has global engineering and manufacturing centers of excellence. For more information on PAR Systems, visit www.par.com.

###