Automated Assembly Systems

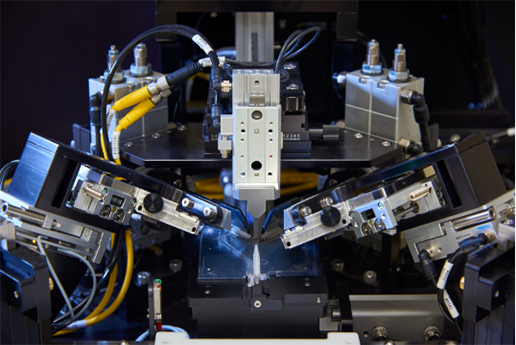

Using the latest technology in vision, motion control, and component handling, PAR Systems has improved the quality of finished goods for hundreds of customers.

From sorting and feeding to assembly and part inspections, we have automated processes on thousands of assembly systems. Our automated assembly machines are customizable, effective, and provide high-quality results. We have extensive experience working within rigorous standards for finished products, from medical devices to semiconductors.

Benefits of Automated Assembly

Significant improvement in cycle time, reduced labor costs, and improved productivity are just the beginning. Automated assembly offers many additional benefits including:

- Ergonomic improvements for repetitive tasks, minuscule parts, or precise movements

- Consistent finished goods quality and accurate assembly

- Ease of operation using our standard software for all systems

- Automated logging with 21 CFR part 11 compliance

- ISO 9001 and 13485 certified project management and documentation approach

Download more information about our automated assembly systems.

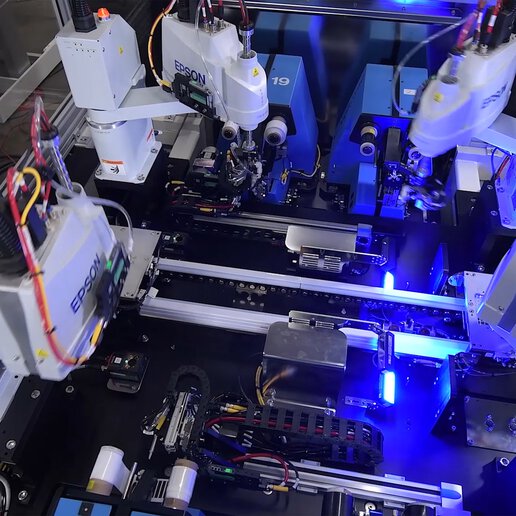

Bringing a full suite of technologies to your assembly challenges.

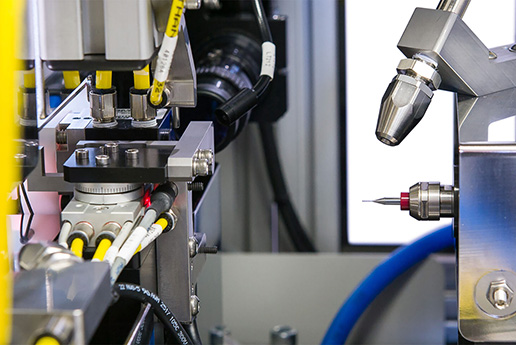

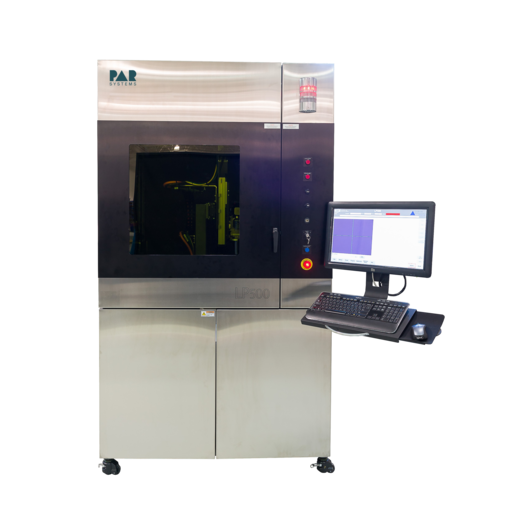

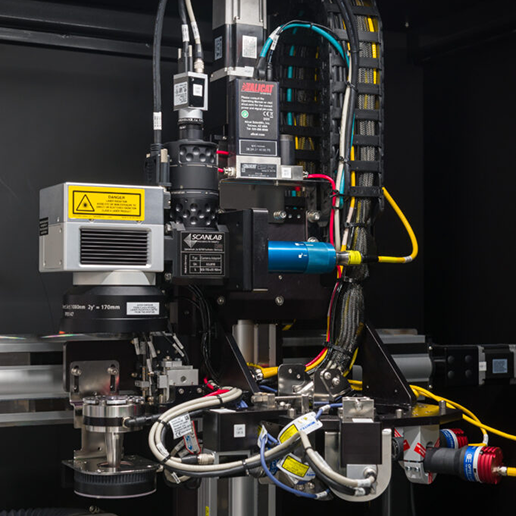

Laser Integration

Solving your process challenges

Laser integration is a core competency in our assembly automation offerings. We have the experience to support your laser cutting and welding, ablation, and soldering processes and can integrate your unique application within a total automation solution.

Laser Processing

Customized to your needs

Our laser processing machines are easily configurable to accommodate specific applications with customizable product fixturing along with simple and user-friendly programming. Our Laser Platforms LP500 can perform laser welding or laser surface treatment. Automating these processes can improve safety, quality, and yield.

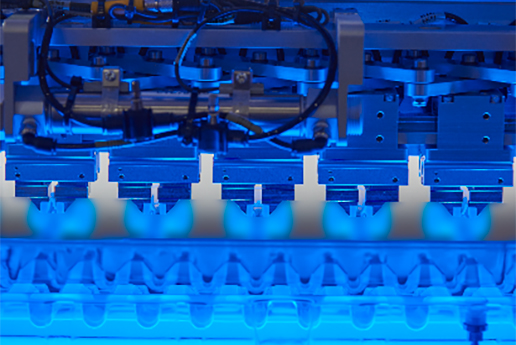

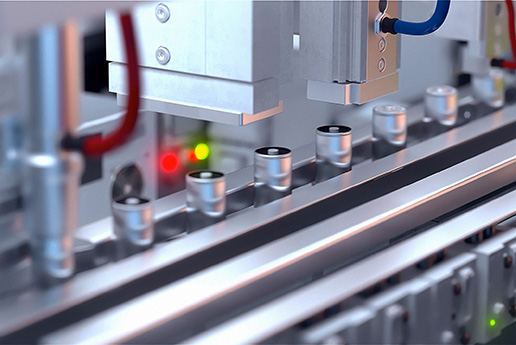

Component Feeding

Optimize part handling

Component feeding is often a core function of assembly automation and one that we specialize in. Our automated feeding capabilities include material and parts feeding, web and wire handling, and flex feeding.

We automate the handling of components from very small precision parts destined for medical devices to very large parts destined for rockets and for many things in between. We also have capability to automate component and part feeding amongst a wide range of materials.

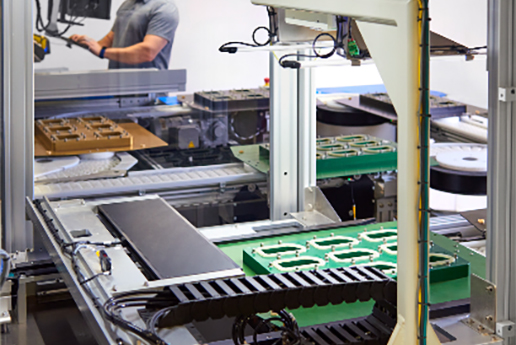

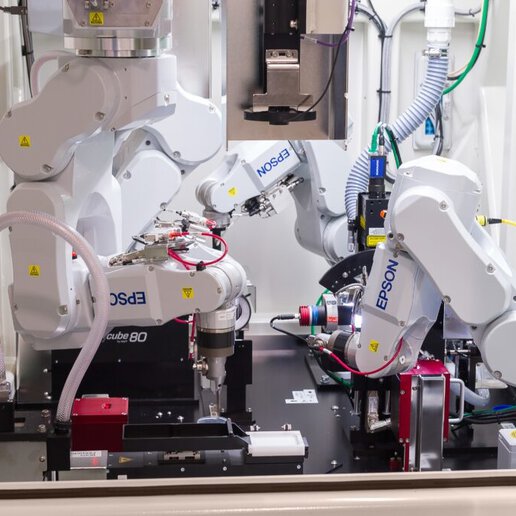

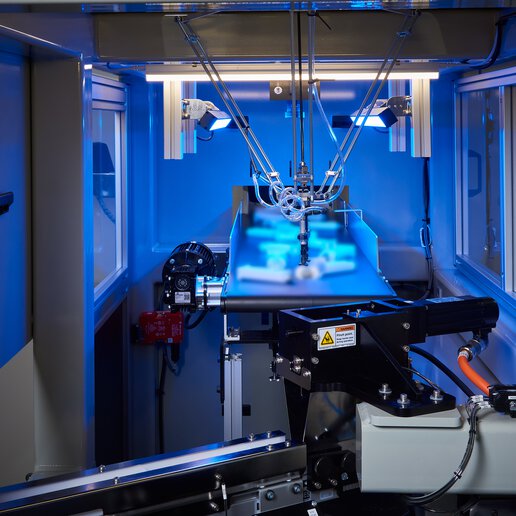

Final Assembly

A purposeful approach.

Every automation need is different, and each requires an approach that fits the needs of the application. PAR offers a wide-range of system layouts and base technologies, including semi-auto stations, conveyor-linked work cells, cam-driven machines, smart conveyance technologies, dial plates, walking beams, web lines, robots, gantries, and more.