Material Removal

PAR Systems automated material removal systems provide customized, high-tech solutions to maximize your productivity, precision, and safety—whether machining composite parts, metallic components, or other materials.

Benefits of Automating Material Removal

Material removal processes—such as cutting, grinding, deburring, and polishing—can pose significant environmental health and safety risks. Automating these tasks not only improves workplace safety but also drives major gains in productivity and quality.

Robotic automation eliminates the need for dedicated tooling through flexible fixturing, reducing changeover time and increasing system adaptability. Automated material removal enhances cycle times, lowers manufacturing costs, and minimizes setup and part positioning requirements.

The result? Faster production, consistently high-quality output, and safer working conditions.

Our systems also support adaptive manufacturing, using intelligent feedback to adjust in real time to part variation and process conditions—ensuring optimal performance every cycle.

- Faster cycle times and lower costs

- Flexible fixturing handles part families—no dedicated tooling

- Safer work environments with reduced manual handling

- Multi-part loading speeds up production

- Integrated tools maximize space and efficiency

- PAR-managed systems ensure reliable performance

- Minimal setup and repositioning for quicker runs

- Adaptive profiling for higher accuracy

- Consistent, high-quality results vs. manual methods

Well-versed Experience in Multiple Material Removal Methods

PAR specializes in waterjet cutting, high-speed spindle milling, laser ablation, and ultrasonic milling material removal methods.

Our experience in precise removal control and adaptive manufacturing make us the right fit for your machining and material removal needs. We also specialize in developing adaptive systems for critical components in challenging environments using these technologies.

Precision Automated Cutting & Trimming

From small components to large wing covers, we can provide a cutting and trimming system to maximize the productivity of your operations. Our systems are designed to offer the perfect marriage of precision and efficiency. Learn more about the benefits of our cutting and trimming systems as well as their fully integrated capabilities.

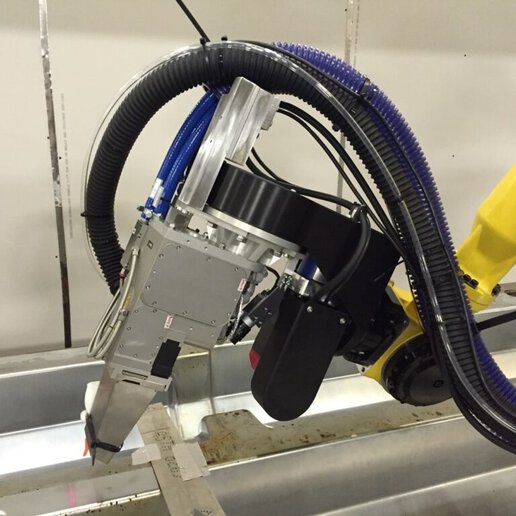

High-Speed Spindle Milling, Grinding, & Cleaning

PAR’s high-speed spindle milling and trimming systems perform cutting and material removal operations precisely and virtually dust-free for a higher quality cut and safer operations. Our automated milling machines typically include RFID enabled automatic tool change capabilities, integrated vacuum dust collection systems, probe systems for part location and machine calibration, and integrated inspection capabilities.

Ultrasonic Cutting & Sculpting

Ultrasonic cutting virtually eliminates friction in the cutting process, allowing for low-force cutting and higher-quality cuts while producing no dust. Ultrasonic cutting and sculpting can be used on a variety of materials such as composites, preforms, aluminum, and core materials. PAR’s ultrasonic cutting systems use both traditional straight knives and rotating discs that expands and contracts at ultrasonic rates to cleanly trim aerospace honeycomb core materials. Our systems can provide a single-station cutting system built on a precision motion platform.

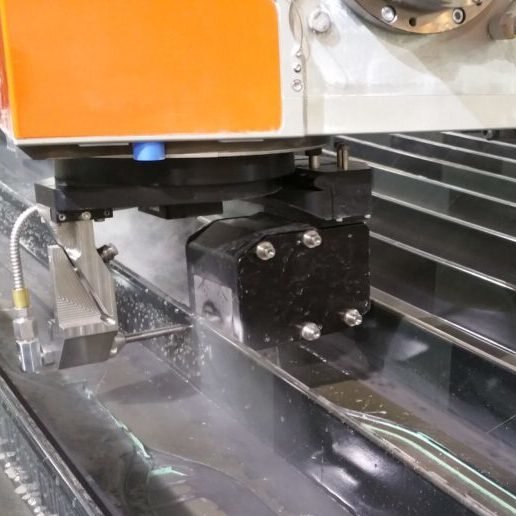

Waterjet Cutting & Trimming

Waterjet cutting and trimming is a perfect solution when materials are susceptible to distortions from other cutting methods such as heat cutting. PAR Systems’ waterjet systems can operate in up to five axes of motion and are designed for a variety of sizes, industries and applications. Our waterjet systems are customizable and configurable to meet your advanced manufacturing needs. Designed and built for your applications, they are available in variable sizes and with multiple add-on options.

Laser Ablation

PAR Systems designs and builds laser ablation systems for removing coatings, debris and residues on parts and materials. We use a robust system design and highly reliable components to deliver high precision solutions designed to meet the specific tolerances for your application at maximum productivity levels. Our systems deliver micro precision to the thousandths of an inch and can build systems that allow you to ablate multiple sides of a part at once.