Material Removal

Milling, Grinding & Cleaning

PAR Systems has expertise in streamlining your milling, grinding and cleaning operations to provide a fully automated solutions that answer all of your material removal needs.

Our Process

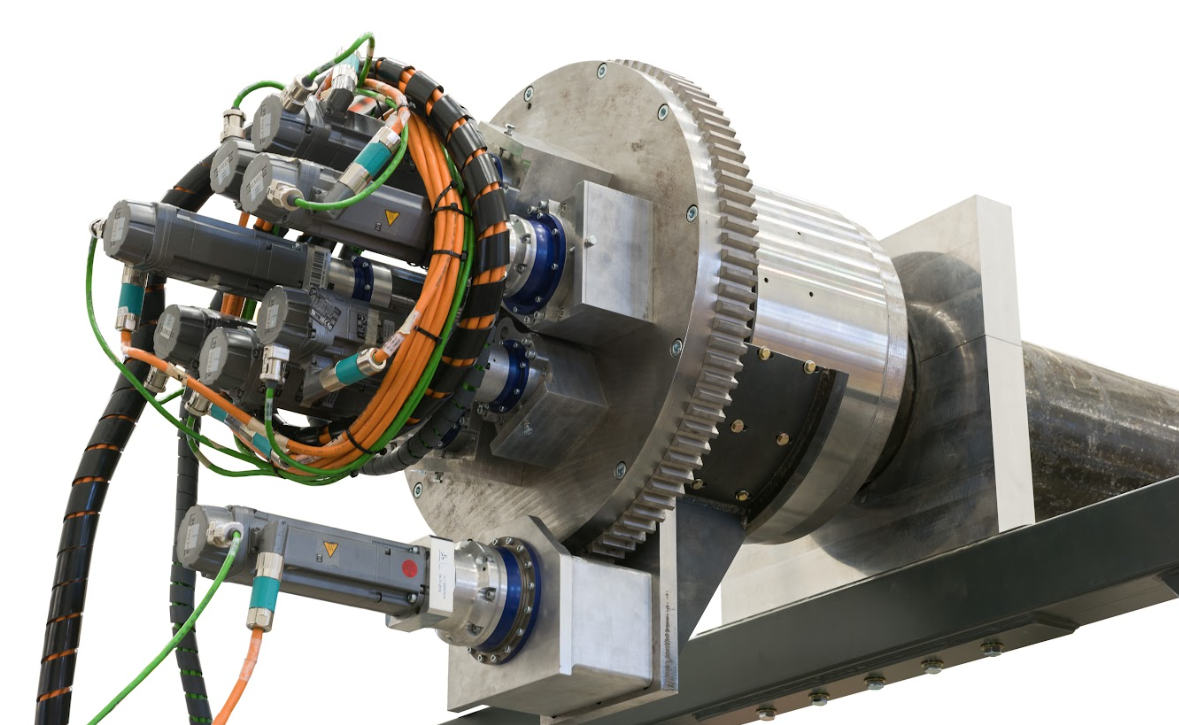

Precision Milling.

Our spindle milling and trimming systems can be integrated into your production line operations. PAR’s solutions are highly customizable and configurable to any unique manufacturing specifications. Our spindle milling and trimming systems can be designed using robotic fixtures of rigid dedicated tools each offering its own advantages depending on the application and environment. Spindle milling and trimming can be used on a variety of materials such as composites, preforms, aluminum, titanium, glass, and ceramic.

We work with the materials you use in every stage of your manufacturing process.

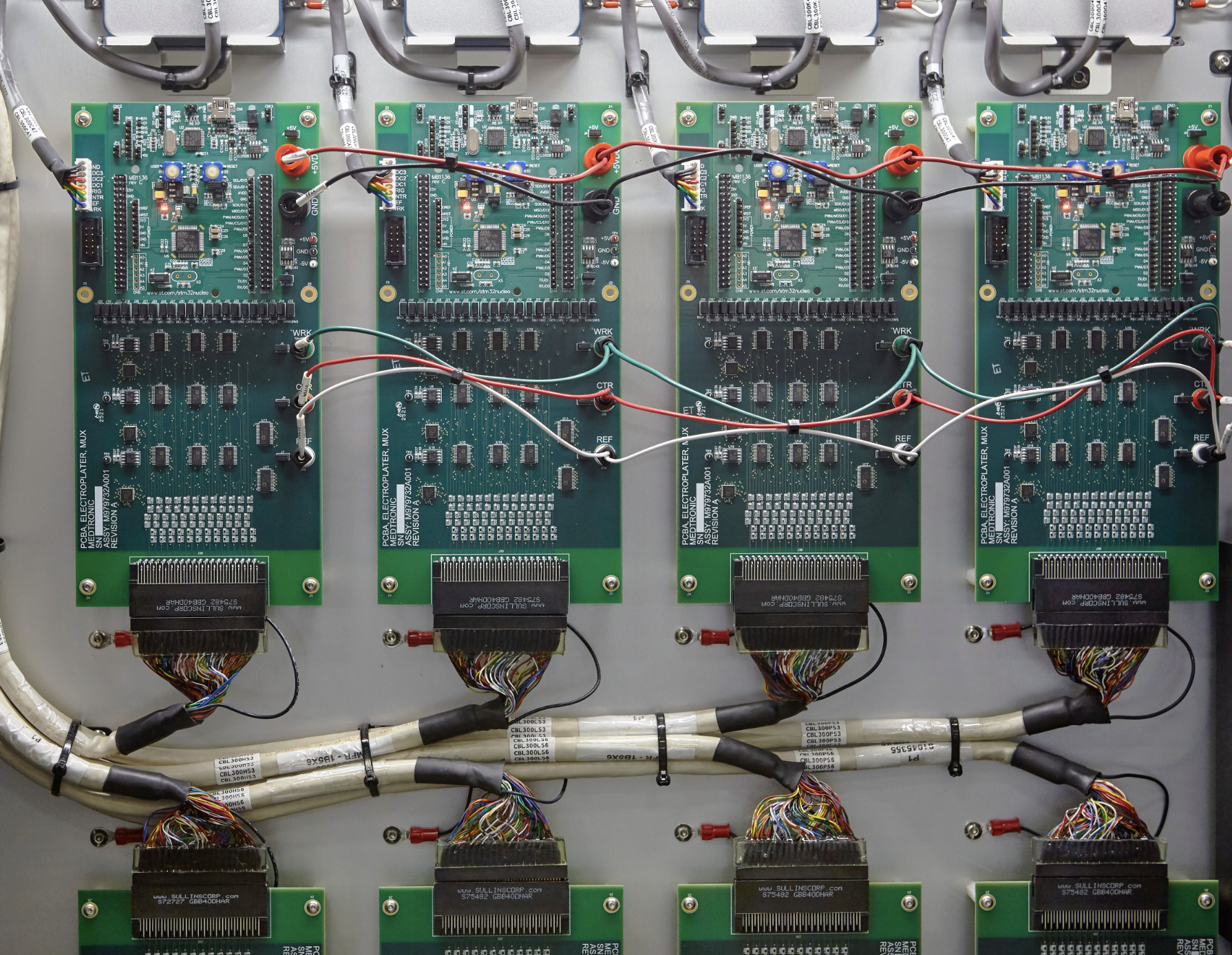

PAR’s automated milling, grinding and cleaning systems work for many different materials and include many fully integrated capabilities such as scanning to determine as-built condition, auto calibration, auto tool change, automated loading systems, and in-process inspection.

Composites

Kevlar

Carbon Fiber

Prepreg

Core

Preforms

Aluminum

Titanium

Glass

Ceramic

Benefits of automating milling, grinding & cleaning.

- Significantly improves cycle time, reduces costs and improves productivity

- Configurable fixturing eliminates need for different tooling for each part or assembly and accommodates families of parts

- Improves health and safety conditions in a manufacturing environment

- With multi-part loading, different parts can be cut more efficiently by combining common processes

- Integrated process head allows multiple process tools to be integrated into a single end effector or machine

- PAR provides total management of the system for highly reliable operations

- Saves time through reduced setup time and part positioning

- Precise profile to match as built conditions

- Consistent quality and better efficiency than iterative, hand-working