Automated Friction Stir Welding

Friction stir welding from PAR Systems is an automated process that uses the most advanced technology on the market and creates multiple efficiencies, saving you time, labor, cost and energy.

At PAR, we thrive on complex problems and excel at execution.

Is Friction Stir Welding Right for Your Application?

Friction stir welding is a solid-state joining process that uses a rotating, non-consumable tool to generate frictional heat to join materials. FSW works with both ferrous and non-ferrous metals, including aluminum.

When compared to conventional arc welding, FSW technology reduces energy consumption during welding by as much as 70%¹

FSW is an optimal choice when you want to weld lightweight alloys, minimize distortion or want an automated process that improves efficiency.

You can save significant capital investment by using PAR’s proof of concept process to determine application feasibility for FSW. If you’re interested in exploring feasibility for your project, use the contact form below to get in touch.

PAR Automated Friction Stir Welding

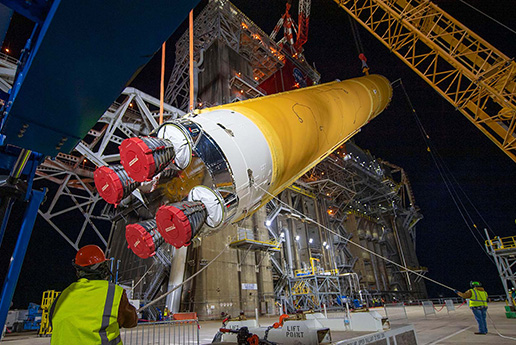

PAR uses the most advanced automated FSW technology on the market, and we have proven experience designing automated FSW systems. This welding method is ideal for the aerospace, marine and nuclear industries and effective for various applications including aerospace passenger planes and space launch vehicles and semiconductor pressure vessels.

- Automation maximizes labor costs, energy and manufacturing efforts

- Repeatable process frontloads investment, reducing production time

- Real-time quality monitoring allows for immediate issue resolution and data acquisition lets customers achieve superior quality welds with the potential to eliminate post-weld inspection

- Welds dissimilar materials and alloys, including aluminum

- Stronger joints than other welds

- No filler materials or foreign object debris

- Exceptional mechanical design, electrical controls and CNC

- Tailored specifically to the application

- Easily follows complex curvatures

- High degree of accuracy = more control

Connect with an

FSW Expert

Aluminum Welding Automation

Friction stir welding is superior to conventional welding methods in part because it works with previously “un-weldable” alloys, including aluminum. Not only does FSW weld these non-ferrous metals, it can produce stronger joints and improved tensile strength compared to fusion welding. FSW also welds in a single pass and minimizes distortion.

Automated aluminum FSW reduces the need for high-touch labor, making your production faster and more efficient.