Friction Stir Welding for Automotive Applications

PAR Systems friction stir welding uses the the most advanced technology on the market and can weld lightweight alloys, including aluminum, to produce lighter, more energy-efficient vehicles.

Is Friction Stir Welding Right for Your Automotive Application?

Friction stir welding is a solid-state joining process that uses a rotating, non-consumable tool to generate frictional heat to join materials. FSW works with both ferrous and non-ferrous metals.

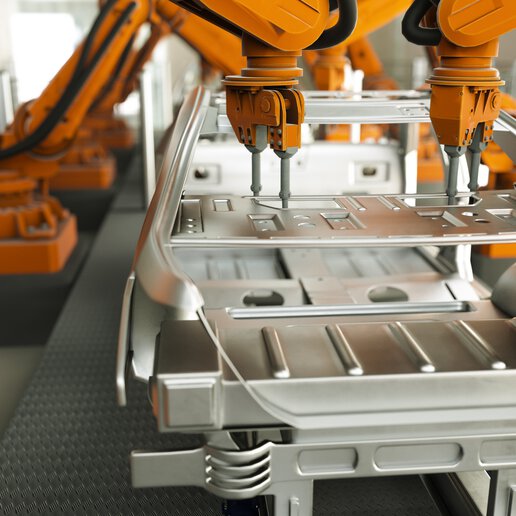

EV battery trays are an ideal application for friction stir welding. FSW outperforms other welds in EV battery trays because it eliminates the need for added materials or rivets and can weld lightweight aluminum alloys, reducing the weight of the tray. It also creates a sealed structure with no gaskets, rivets or seals where there may be ingress from water or other materials.

When compared to conventional arc welding, FSW technology reduces energy consumption during welding by as much as 70%¹

FSW is an optimal choice for both gas and electric vehicle production using aluminum or other lightweight alloys. It also welds different alloys and thicknesses for:

- tailor welded blanks

- bumper beams

- rear spoilers

- suspension links

- alloy wheels

Considering friction stir welding? You can save significant capital investment by using PAR’s proof of concept process to determine application feasibility for FSW. If you’re interested in exploring feasibility for your project, use the contact form below to get in touch.

FSW for Aluminum and Steel

Friction stir welding is superior to conventional welding methods in part because it works with both ferrous and non-ferrous metals, including steel and aluminum. Not only does FSW weld these metals, it can produce stronger joints and improved tensile strength compared to fusion welding. FSW also welds in a single pass and minimizes distortion.

PAR Friction Stir Welding

PAR has proven experience designing complex, customizable friction stir welding solutions.

- Welds lightweight alloys, including aluminum, that are ideal for automotive production

- Economical welding of complex 3D seams

- No filler materials required

- Stronger joints than other welds

- Minimizes distortion

- No ventilation hood or hazardous fumes

- Saves time, labor, cost and energy

- Automated, repeatable process

- Real-time quality monitoring